Introduction

In the world of electronics and industrial applications, momentary switches play a pivotal role in providing users with precise control over electrical circuits. Among these versatile switches, the PBS-105 Red Small 2-Pin Momentary Switch stands out as an efficient and reliable option.

Featuring a striking red color and a compact design, this switch is a popular choice for various start-stop operations. In this article, we will delve into the details of the PBS-105 momentary switch, highlighting its features, applications, and the benefits it offers in diverse settings.

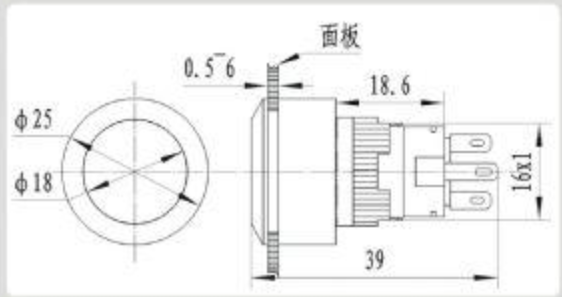

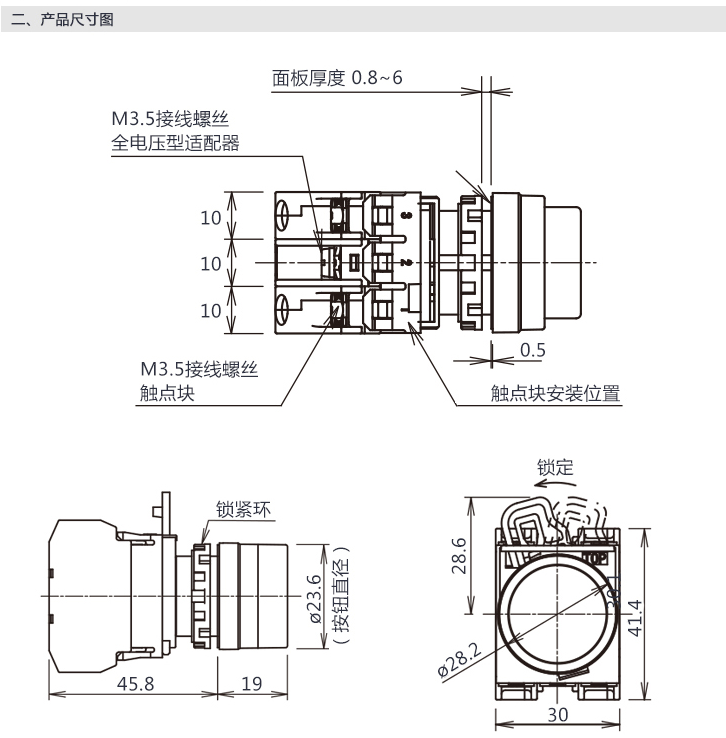

FILN Momentary Switch Drawing

| Production Series | FLM7-10FJM | Light Guide Button | PC plastic |

| Button Shape | round | Actuator | 304 Stainless steel |

| Button LED Color | Housing Sleeve | H59 nickel plated brass/304Stainless steel | |

| Mechanical Life | The 500 thousand time | Button Pin | H62 copper alloy |

| Electrical Life | The 100 thousand time | Rubber Ring | SIL silica gel |

| Protection Level | IP67 IK09 | Nut | H59 nickel plated brass |

| Rated Voltage | 240V(DC) 250V(AC) | Housing | PA66+GF20% nylon |

| Rated Current | 3A(DC)0.5A(AC) | Light Source | LED |

| Rated Power | 180W(DC)1250W(AC) | Resistor | Metal film |

| Operating Temperature | -25℃~+85℃ | Contact | AgCdO12 |

Understanding the PBS-105 Momentary Switch

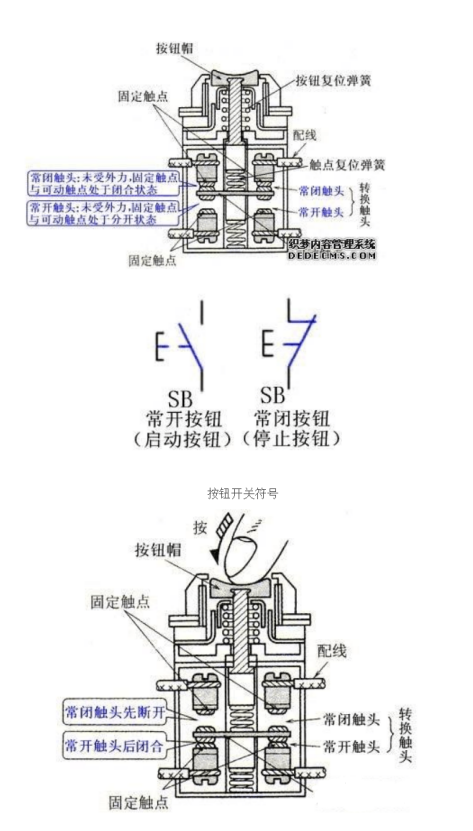

The PBS-105 momentary switch is known for its momentary action, meaning it remains active only while pressure is applied to its actuator. As soon as the actuator is released, the switch returns to its default state.

This unique functionality is ideal for applications requiring temporary or on-demand control, preventing accidental activations and providing users with greater precision.

Key Features of the PBS-105 Momentary Switch

1. Red Button Design

The PBS-105 momentary switch features a vibrant red button that adds visibility to control panels and devices. The red color stands out, making it easy for users to locate and activate the switch when needed. This feature is particularly beneficial in critical applications where quick access is essential.

2. Compact Size and 2-Pin Configuration

The switch’s small form factor allows for convenient integration into various electronic devices and systems. Its 2-pin configuration simplifies installation, making it an excellent choice for projects with limited space. Despite its compact size, the PBS-105 switch offers efficient performance and reliability.

3. Momentary OFF-(ON) Operation

The (OFF)-(ON) configuration of the PBS-105 momentary switch indicates that the switch is normally in the “OFF” state. Upon pressing the actuator, it becomes momentarily active in the “ON” state. Once the pressure is released, the switch returns to its default “OFF” state. This operation is essential for applications requiring short bursts of electrical connection.

4. Current Handling Capacity

The PBS-105 momentary switch is designed to handle currents up to 0.5A. While it is suitable for low-power circuits, it remains efficient and reliable in its specified range. This makes it ideal for a wide range of consumer electronics and small-scale industrial applications.

5. Compatibility with 12V Circuits

The PBS-105 momentary switch is engineered to operate seamlessly with 12V circuits. This compatibility allows it to be used in various electronic devices, gadgets, and systems operating within the 12V range.

Applications of the PBS-105 Momentary Switch

The PBS-105 momentary switch finds extensive use in diverse industries and applications, owing to its unique features and reliable performance.

1. Consumer Electronics

In the realm of consumer electronics, the PBS-105 momentary switch serves as a vital component in products such as remote controls, kitchen appliances, and small handheld devices. It acts as a power button, mode selector, or reset switch, offering users precise control over their devices.

2. Industrial Automation

The PBS-105 momentary switch is widely employed in industrial automation settings. Its use in control panels, machinery, and equipment facilitates start-stop operations, emergency shutdowns, and safety interlocks. These switches ensure the efficient and secure automation of industrial processes.

3. Gaming and Entertainment

The responsive and tactile feedback of momentary switches like the PBS-105 makes them an excellent choice for gaming controllers. Gamers benefit from precise inputs during gameplay, enhancing their overall gaming experience.

4. Automotive Applications

Momentary switches are also prevalent in the automotive industry, where they are utilized for functions such as activating lights, horns, or window controls. The PBS-105’s momentary action ensures that these functions are triggered only when necessary, enhancing energy efficiency and safety.

Conclusion

The PBS-105 Red Small 2-Pin Momentary Switch is a powerful and efficient component, offering precise control and momentary operation. With its compact design, vibrant red button, and compatibility with 12V circuits, it finds applications in various consumer electronics, industrial automation, gaming, and automotive systems.

Whether it’s providing users with convenient control in electronic gadgets or ensuring safe operations in industrial settings, the PBS-105 momentary switch continues to be a popular and reliable choice.

FAQs

- What is the color of the PBS-105 momentary switch? The PBS-105 momentary switch features a vibrant red button, adding visibility and making it easy for users to locate and activate the switch.

- Can the PBS-105 momentary switch handle high currents?

The PBS-105 momentary switch is designed to handle currents up to 0.5A, making it suitable for low-power circuits and applications. - Is the PBS-105 momentary switch suitable for automotive use?

Yes, the PBS-105 momentary switch is commonly used in automotive applications, such as activating lights, horns, or window controls, providing precise control when needed. - Does the PBS-105 momentary switch have a momentary action?

Yes, the PBS-105 momentary switch operates in a momentary (OFF)-(ON) configuration, meaning it remains active only while pressure is applied to the actuator. - What voltage range is the PBS-105 momentary switch compatible with?

The PBS-105 momentary switch is engineered to operate seamlessly with 12V circuits, making it compatible with various electronic devices and systems.

A Comprehensive Guide to Mini Push Button Switch 2 Pin: Everything You Need to Know

The mini push button switch 2 pin is a fundamental yet vital component in the world of electronics, finding its place in numerous applications ranging from simple on/off controls to intricate Arduino projects. This comprehensive guide delves into everything you need to know about the 2 pin push button switch, including its functionality, wiring process, differences with the 4 pin version, troubleshooting, alternatives, safety considerations, and even its use with Arduino platforms. Whether you’re a hobbyist or a professional, understanding the various aspects of these switches can enhance your projects and streamline your work. Continue reading to explore the multifaceted world of mini push button switches and uncover tips, tricks, and insights that cater to all skill levels.

What is a Mini Push Button Switch 2 Pin and How Does It Work?

Definition and Working Principle

A mini push button switch 2 pin is a small electronic switch designed to control the flow of electricity. By pressing the button, users can close or open the circuit, allowing or stopping the current flow. This type of switch is commonly found in various electronic devices. Find more details about the on/off functionality here.

Design and Components

Mini push button switches often come with a simple design, consisting mainly of a casing, 2 pins, and a spring mechanism that ensures the button returns to its original position when released.

Applications

These switches are used in various applications, such as controlling lights, signals, motors, and other electrical devices. They are favored for their compact size and reliability.

What’s the Difference Between 2 Pin and 4 Pin Mini Push Button Switches?

2 Pin Mini Push Button Switch

2 pin push button switches are basic in design and come with two terminal pins. One pin is connected to the power source, while the other is connected to the device. When the button is pressed, the circuit is completed. Explore 2 pin push button switch connection here.

4 Pin Mini Push Button Switch

On the other hand, 4 pin mini push button switches offer more complex connections. These include two pins for input and two for output, allowing for more versatile control options. Find more information about the 4-pin connection here.

Comparison

- Functionality: 4 pin switches offer more functionality, including latching or momentary actions.

- Complexity: 2 pin switches are simpler and more straightforward to wire.

- Applications: 4 pin switches are suited for more complex control systems.

How to Wire a Mini Push Button Switch 2 Pin?

Necessary Tools

To wire a mini push button switch 2 pin, you will need some basic tools such as wire strippers, a soldering iron, and a multimeter.

Step-by-Step Guide

- Identify the pins: Determine which pin is connected to the power source and which is connected to the device.

- Strip the wires: Using wire strippers, strip the ends of the wires.

- Connect the wires: Solder or crimp the wires to the respective pins.

- Test the connection: Use a multimeter to ensure proper connectivity.

Click here for detailed guidance on push switch with terminal pins.

How to Choose the Right Mini Push Button Switch 2 Pin for Your Project?

Understand the Requirements

Before selecting a mini push button switch 2 pin, consider your project’s specific requirements, such as voltage, current rating, and the type of action needed (momentary or latching).

Consider the Material

Choose the material that suits your application, such as plastic for lightweight or metal for durability. Find various 12mm metal miniature push button switches here.

Check the Specifications

Ensure that the specifications like voltage rating, current capacity, and size match your project needs. Always refer to the manufacturer’s datasheet.

Compare Prices and Brands

Look for reputable brands and compare prices to find a switch that offers both quality and value.

Consider Environmental Factors

If your application requires a waterproof switch, opt for a micro push button switch that offers waterproof capabilities. Check out the micro push button switch waterproof options here.

How to Troubleshoot a Mini Push Button Switch 2 Pin?

Visual Inspection

Start by visually inspecting the switch for any visible damage or loose connections.

Test the Continuity

Use a multimeter to test the continuity. If there’s no continuity when the button is pressed, the switch may be faulty.

Check the Wiring

Ensure that the wiring is correct and that there are no loose or broken connections.

Replace if Necessary

If the switch is found to be defective, replace it with a new one of the same specifications. Find a suitable replacement here.

What are the Alternatives to Mini Push Button Switch 2 Pin?

Toggle Switches

Toggle switches offer a more substantial feel and are suitable for applications requiring a clear ON/OFF position.

Rotary Switches

Rotary switches allow users to select multiple positions, making them suitable for applications requiring multiple options.

Slide Switches

Slide switches are operated by sliding a lever and can be used in applications that require a slim profile.

Micro Push Button Switch 4 Pin

Micro push button switch 4 pin offers more complex control options, making them an alternative to the basic 2 pin switches. Find various 4 pin switches here.

What are the Safety Considerations When Using a Mini Push Button Switch 2 Pin?

Proper Wiring

Ensure that the wiring is done correctly to avoid short circuits or electrical hazards.

Appropriate Ratings

Always use a switch with the correct voltage and current ratings for your application.

Proper Installation

Make sure to install the switch securely to prevent it from coming loose during operation.

Compliance with Standards

Choose switches that comply with safety standards and regulations relevant to your region.

Maintenance

Regular inspection and maintenance are crucial to ensure the safe and proper functioning of the switch. Find more about switch maintenance here.

How to Use a Mini Push Button Switch 2 Pin with Arduino?

Understanding the Connection

A 2 pin push button switch can be easily connected to an Arduino board for various projects. One pin is connected to a digital pin on the Arduino, and the other is connected to the ground.

Programming

Use the Arduino IDE to write the code that will define how the switch will function in your project.

Example Projects

Examples of projects include controlling LEDs, triggering alarms, or navigating menus on an LCD.

Tutorials and Resources

There are various tutorials and resources available online to guide you through the process. Explore Arduino-related push button switches here.

Conclusion

Mini push button switch 2 pin is a versatile and commonly used electronic component. Understanding its design, wiring, applications, alternatives, and safety considerations is essential for hobbyists and professionals alike. From simple on/off control to more complex connections with Arduino, these switches provide various functionalities that cater to different project needs. By considering the above aspects and referring to the provided resources, one can effectively choose, wire, troubleshoot, and utilize these switches in a multitude of applications.

Popular Product:

Popular Product:

Popular Product:

Popular Product: