Product Drawings:

Product Parameters:

| Production Series | FLM16-11FJ | Light Guide Button | |

| Button Shape | round | Actuator | 304 Stainless steel |

| Button LED Color | Housing Sleeve | H59 nickel plated brass/304Stainless steel | |

| Mechanical Life | The 500 thousand time | Button Pin | H62 copper alloy |

| Electrical Life | The 100 thousand time | Rubber Ring | SIL silica gel |

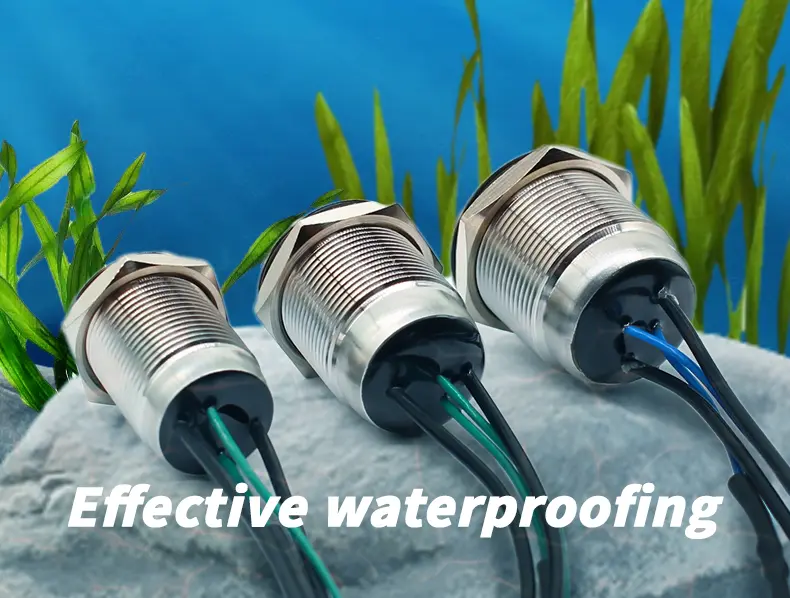

| Protection Level | IP65 IK09 | Nut | H59 nickel plated brass |

| Rated Voltage | 36V(DC) 250V(AC) | Housing | PA66+GF20% nylon |

| Rated Current | 5A(DC)5A(AC) | Light Source | |

| Rated Power | 180W(DC)1250W(AC) | Resistor | |

| Operating Temperature | -25℃~+85℃ | Contact | AgCdO12 |

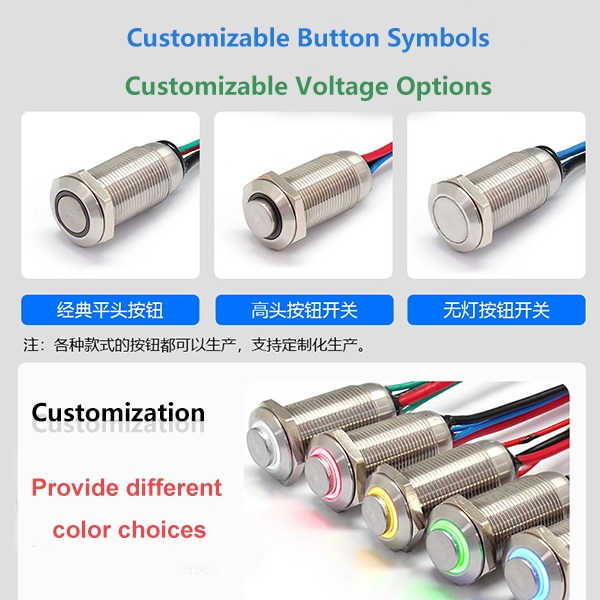

FILN Pushbutton Switch Customization

Advantages of Customization:

- Personalization: Symbols tailored to individual preferences.

- Customizable Voltage and Color: Tailored voltage and color options.

- Diverse Wiring Options: Multiple wiring methods to suit diverse needs.

- More Affordable Pricing: Cost-effective pricing choices.

Applications:

- Industrial Applications

- Home Automation

- Automotive Integration

- Medical Devices

- Consumer Electronics

- Public Infrastructure

- Commercial Use

- Security Systems

- Hospitality Industry

- Transportation Use

Related products:

Small Momentary Switches: A Comprehensive Guide to Usage, Types, and Applications

Small momentary switches are integral components in numerous applications, ranging from industrial machinery to everyday electronic devices. This comprehensive guide delves into the world of momentary switches, exploring their types, functions, sourcing strategies, regulatory standards, evolution, common myths, and innovative uses. Whether you’re a seasoned engineer or a curious hobbyist, understanding these switches’ multifaceted aspects can enrich your projects and inspire creative applications. Join us as we unravel the nuances and potential of small momentary switches to fuel your next innovation!

What Are Small Momentary Switches, and How Are They Used?

Small momentary switches, also referred to as momentary micro switches, are switches that only remain in their “on” or “off” state while being actuated. These switches are used in various applications and devices, from everyday household gadgets to industrial machinery. In this section, we’ll explore three perspectives on their function and usage.

Understanding the Basics:Small momentary switches are designed to change their state only when pressure is applied, returning to their default position when released. This function makes them suitable for applications where temporary control is required.

Common Applications:These switches are commonly found in doorbells, car starters, keyboard keys, and more. They can be used to control electrical signals, initiate actions, or provide immediate response in various devices. The momentary waterproof 12V round switches are perfect examples of such applications.

Varieties and Specifications:Small momentary switches come in various forms, including momentary push-button switch, 12-volt momentary push-button switch, and others. Different specifications can be tailored to unique needs, like the miniature push-button switch, providing compact and efficient performance.

What Are the Advantages and Disadvantages of Small Momentary Switches?

Understanding the pros and cons of small momentary switches is crucial for selecting the right type for a particular application. This section will explore the advantages and disadvantages from three different perspectives.

Advantages

- Efficiency: These switches provide efficient control as they return to their default state automatically, reducing the chance of accidental continuous activation.

- Versatility: With options such as the 12-volt momentary push-button switch, they can be used in various devices and applications.

- Affordability: Many momentary switches are cost-effective, making them an attractive choice for budget-conscious projects.

Disadvantages

- Limited Control: Since they only remain active while pressed, they might not be suitable for applications requiring continuous activation.

- Wear and Tear: Frequent usage might lead to quicker wear and tear, demanding regular replacement.

- Sensitivity Issues: Some designs might be too sensitive or require a specific force to actuate, which can cause usability challenges.

How to Choose the Right Small Momentary Switch for Your Project?

Choosing the right momentary micro switch is vital for the efficiency and effectiveness of your project. In this section, we will look at three aspects to consider when selecting the proper switch.

Determine the Requirements:Understanding the specific needs of your project, such as voltage, current, size, and actuation force, will guide your selection. For specific applications like waterproofing, you might consider options like the IP65 momentary mini push-button switch.

Consider the Application:Identifying the specific application and environment where the switch will be used can also influence the selection. Different applications like industrial machinery or household appliances might require different types of momentary switches.

Evaluate Quality and Budget:Balancing quality and budget is crucial. It’s essential to find a switch that meets the quality standards without overshooting the budget. Brands and suppliers like Indicator Light offer a wide range of options to choose from.

What Are the Different Types of Momentary Push Button Switches?

There are numerous types of momentary push-button switches tailored for different needs and applications. We’ll explore these from three different viewpoints, focusing on functionality, design, and special features.

Functionality-Based Types

- Normally Open: These switches complete the circuit only when pressed, and examples include momentary push-button switch normally open.

- Normally Closed: The circuit remains closed until the switch is pressed, opening the circuit momentarily.

Design-Based Types

- Miniature: Compact in design, options like miniature momentary push-button switch are suitable for small devices.

- With LED: Incorporating LEDs, such as momentary push-button switch with LED, adds visual feedback to the operation.

Special Features

- Waterproof: Some switches are designed to resist water, like waterproof momentary switch.

- Starter Switches: Specific designs are tailored for starting engines, such as momentary car push-button ignition switch.

How to Install and Maintain Small Momentary Switches?

Proper installation and maintenance are key to ensuring the long-term functionality of small momentary switches. This section will provide a guideline from three angles: installation, troubleshooting, and maintenance.

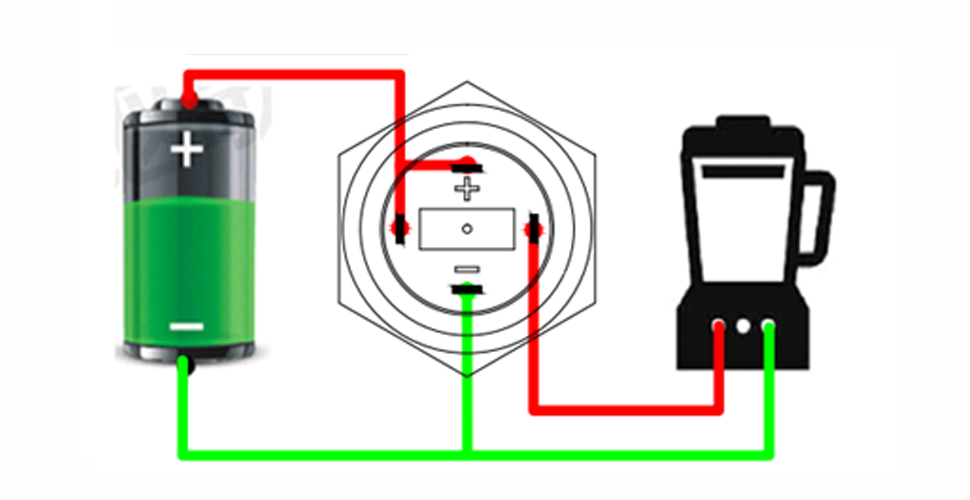

Installation Guidelines

- Understanding the Diagram: Knowing how to read a momentary push-button switch diagram is essential for proper wiring and connections.

- Using the Right Tools: Specific tools might be needed for installation, ensuring a secure fit and proper connection.

- Following Safety Precautions: Taking appropriate safety measures, including disconnecting power during installation, is vital.

Troubleshooting Tips

- Identifying Common Issues: Recognizing common problems like unresponsive switches or intermittent connections can aid in swift repairs.

- Utilizing Multimeters: Using multimeters to check for continuity and resistance helps in diagnosing the underlying issues.

- Consulting Manuals: Manufacturer’s manuals and guides, such as those provided by Indicator Light, offer detailed troubleshooting steps.

Maintenance Recommendations

- Regular Inspection: Regularly inspecting the switches for wear, corrosion, or other damages helps in early detection of issues.

- Cleaning: Keeping the switches clean from dust and debris can prolong their life and efficiency.

- Replacement Planning: Having a plan for replacement, such as keeping spare switches like small push-button switch, ensures minimal downtime in case of failure.

How to Source Small Momentary Switches?

Finding the right source for purchasing small momentary switches involves considering various factors. We’ll explore three viewpoints: local sourcing, online purchasing, and customized orders.

Local Sourcing

- Retail Stores: Local electronics stores might carry standard momentary switches suitable for common applications.

- Wholesale Suppliers: Working with local wholesale suppliers can provide bulk purchasing options and possibly discounted rates.

- Specialty Shops: Some specialized shops may carry unique or specialized momentary switches, such as 12mm momentary switch.

Online Purchasing

- Online Retailers: Websites like Amazon and eBay may carry various momentary switches, providing a wide selection.

- Manufacturer:Buying directly from manufacturers like [Indicator Light]

icatorlight.com/momentary-switch-push-button/) can provide authentic products and support.

- Global Marketplaces: Platforms like Alibaba connect global suppliers and buyers, offering diverse options for sourcing.

Customized Orders

- Tailored Specifications: Some suppliers allow custom orders to match specific requirements, such as the momentary 220V push button switch.

- Collaboration with Manufacturers: Collaborating with manufacturers for customized designs can provide unique solutions tailored to specific needs.

- Contract Manufacturing: Utilizing contract manufacturing services for large or complex orders can ensure consistent quality and delivery.

What Regulations and Standards Govern Small Momentary Switches?

Compliance with regulations and standards is crucial in the manufacturing and usage of momentary micro switches. This section will cover three perspectives on regulations: international standards, regional compliance, and industry-specific guidelines.

International Standards

- IEC Standards: International Electrotechnical Commission (IEC) standards apply globally, defining the general requirements for switches.

- RoHS Compliance: Restriction of Hazardous Substances (RoHS) compliance ensures that the switches do not contain harmful materials.

- CE Marking: Compliance with CE marking indicates that the switches meet EU safety and environmental requirements.

Regional Compliance

- FCC Compliance in the USA: Meeting the Federal Communications Commission (FCC) standards ensures the switches don’t interfere with radio frequency communications.

- CCC Certification in China: China Compulsory Certification (CCC) ensures the product meets Chinese safety and quality standards.

Industry-Specific Guidelines

- Automotive Standards: Specific standards apply to momentary switches used in automotive applications, ensuring reliability and safety.

- Medical Device Compliance: Switches used in medical devices must meet particular regulations to ensure patient safety and device effectiveness.

How Have Small Momentary Switches Evolved Over Time?

The evolution of small momentary switches has been influenced by technological advancements, industry needs, and consumer demands. We will explore this evolution from three perspectives: historical development, technological advancements, and future trends.

Historical Development

- Early Inventions: The basic principles of momentary switches date back to the early 20th century, with simple mechanical designs.

- Industrial Usage Growth: The expansion of industrial machinery led to the growth of various types of momentary switches, including 110V momentary push-button switch.

- Consumer Electronics Integration: The rise of consumer electronics further diversified the types and applications of momentary switches.

Technological Advancements

- Miniaturization: The development of miniature momentary push-button switches enabled integration into smaller and more complex devices.

- Material Innovation: The use of new materials enhanced durability and allowed for features like waterproofing.

- Smart Integration: The integration of smart technologies, such as IoT, expanded the functionality and connectivity of momentary switches.

Future Trends

- Eco-Friendly Designs: The push towards sustainability is leading to the development of environmentally friendly momentary switch designs.

- Increased Customization: The demand for tailor-made solutions will likely lead to more customizable and adaptable momentary switch options.

- Integration with Emerging Technologies: Continued integration with emerging technologies like artificial intelligence and automation will shape the future landscape of momentary switches.

What Are Some Common Myths and Misconceptions About Small Momentary Switches?

Understanding common myths and misconceptions about small momentary switches can prevent misunderstandings and wrong choices. In this section, we’ll debunk three common myths.

Myth 1: All Momentary Switches Are the Same

This misconception often leads to incorrect purchases and misunderstandings. In reality, there are various types, specifications, and designs, such as momentary push-button switch 4-pin, each serving different purposes.

Myth 2: Momentary Switches Are Only for Industrial Use

While they are widely used in industrial applications, momentary switches are also found in everyday devices like keyboards, toys, and remote controls.

Myth 3: Momentary Switches Are Difficult to Install and Maintain

Though some specialized applications might require expert handling, many momentary switches are user-friendly and come with clear guidelines for installation and maintenance, such as those available on Indicator Light’s website.

How Can Small Momentary Switches Be Used in Innovative Ways?

The versatility of small momentary switches allows for creative and innovative applications. This section will explore three unconventional uses and innovations related to momentary switches.

Interactive Art Installations:Artists are incorporating momentary switches into interactive art pieces, allowing viewers to engage and control aspects of the artwork.

Adaptive Accessibility Devices:Momentary switches can be customized for adaptive technologies, providing accessibility solutions for individuals with disabilities, such as custom control interfaces.

Educational DIY Kits:Educational kits incorporating momentary switches, like momentary button, are used to teach electronics and engineering principles to students in an interactive and hands-on way.

Summary:Small momentary switches are versatile components found in various applications, from industrial machines to household gadgets. Understanding their types, applications, advantages, disadvantages, and innovative uses helps in making informed decisions for projects and applications. Whether you are a hobbyist, engineer, or manufacturer, this comprehensive guide provides insights into the world of momentary switches and assists in choosing the right switch for your specific needs.

If you are looking for a push button switch for your project, you may have come across the term “momentary meaning” and wondered what it means. In this article, we will explain what momentary meaning is, how it differs from other types of push button switches, and how to choose the right one for your needs.

What is Momentary Meaning?

Momentary meaning is a term that describes how a push button switch operates.

A push button switch is a type of switch that has a button that can be pressed to make or break an electrical circuit. A momentary push button switch is one that only maintains the circuit while the button is pressed.

As soon as the button is released, the circuit is broken.

For example, a doorbell is a common example of a momentary push button switch. When you press the button, the bell rings, but when you release the button, the bell stops. The circuit is only completed when the button is pressed.

Other types of push button switches include maintained or latching switches, which stay in the same position until they are pressed again.

For example, a light switch is a maintained push button switch. When you press the switch, the light turns on and stays on until you press the switch again to turn it off.

How to Choose the Right Push Button Switch?

There are many factors to consider when choosing a push button switch for your project, such as:

- The voltage and current rating of the switch

- The size and shape of the switch

- The color and style of the switch

- The mounting type and location of the switch

- The environmental conditions and protection level of the switch

However, one of the most important factors is the function of the switch. Depending on your application, you may need a momentary or a maintained push button switch.

A momentary push button switch is suitable for applications that require a temporary or intermittent action, such as:

- Starting or stopping a machine

- Sending a signal or command

- Activating an alarm or emergency stop

- Testing or resetting a device

A maintained push button switch is suitable for applications that require a permanent or continuous action, such as:

- Turning on or off a light or fan

- Selecting a mode or option

- Locking or unlocking a door

- Controlling a volume or speed

Where to Buy Push Button Switches?

If you are looking for high-quality and affordable push button switches, you can visit FILN as an Online Shop. We are a leading supplier of push button switches and other electrical components. We offer a wide range of push button switches with different features and specifications. Whether you need a momentary or a maintained push button switch, we have it all.

You can browse our online catalog and find the perfect push button switch for your project. You can also contact us if you have any questions or need any assistance. We are always happy to help you.

Conclusion

Push button switches are simple but versatile devices that can be used for various purposes.

Momentary meaning is one of the terms that describe how a push button switch operates. A momentary push button switch only maintains the circuit while the button is pressed, while a maintained push button switch stays in the same position until it is pressed again.

Depending on your application, you may need either type of push button switch.

You can find both types of push button switches at FILN, where we offer high-quality and affordable products.

We hope this article has helped you understand what momentary meaning is and how to choose the right push button switch for your project.

If you have any questions or comments, please feel free to leave them below. Thank you for reading.

FILN specializes in producing momentary push button switches, and has an important position in the industry. Our buttons have the largest variety in the country, based on different sizes, shapes, functions, colors, voltage, and specifications.

To better serve our global customers, our products have obtained ROHS, CE, VDE, UL, ISO9000 and other quality certifications. Currently, our momentary push button switches have been widely used in Europe, America, North America, Asia, South Africa, Southeast Asia and other regions.

Our momentary push button switches have significant meanings and have a wide range of applications.

Whether it’s packaging machines, coffee machines, water dispensers, automatic labeling machines, or household appliances such as ovens, electric frying pans, washing machines, refrigerators, massage chairs, our products can provide high-quality switching functions for them.