What is Waterproof Push Button?

There are many types of push button switches on the market, one of which is water resistant and is usually referred to as a push button switch waterproof, which can also be called push button switch waterproof.

There is no doubt that this type of button is for use in environments with water, most commonly in some large kitchen equipment, where water is needed for daily operation and cleaning, so a push button switch that is waterproof is especially needed.

An In-Depth Guide to Waterproof Push Button: Types, Features, and Applications

Waterproof push buttons are an integral part of modern technology, offering both functionality and aesthetic appeal in various applications. These buttons, designed to withstand harsh conditions, are available in numerous forms, such as waterproof momentary switches, waterproof on/off switches, and more. This comprehensive guide explores everything you need to know about waterproof push buttons, including their design, applications, innovations, selection process, maintenance practices, safety precautions, and purchasing options. Whether you’re an industry professional or someone looking to understand the essentials of these versatile buttons, this article provides an in-depth look that will equip you with the knowledge and insights you need.

H2: What are Waterproof Push Buttons and How Do They Work?

H3: Definition and Basics of Waterproof Push Button

Waterproof push buttons are specially designed switches that remain unaffected by water or moisture. They are essential in many industrial, marine, and outdoor applications where standard push buttons might malfunction due to water exposure.

H3: Working Mechanism

Waterproof push buttons work on the same principle as regular push buttons, but with an added layer of protection against water and moisture. This additional waterproofing allows the button to function effectively in environments where there might be contact with water or high humidity.

H3: Types of Waterproof Push Buttons

There are various types of waterproof push buttons, including momentary, latching, on/off switches, and more. Each type serves a unique purpose and can be found in different applications.

- Momentary Waterproof Push Buttons: These switches are only active when pressed. Here you can find more details about waterproof momentary switches.

- Latching Waterproof Push Buttons: They remain in their last state after being pressed, offering a different kind of control.

- Waterproof On/Off Switches: These switches allow control over power flow and are used in various applications.

H2: What are the Applications of Waterproof Push Buttons?

H3: Marine Usage

Waterproof push buttons are indispensable in marine applications due to the constant exposure to water and salt. Marine push button switches are designed to handle these extreme conditions, ensuring functionality on boats, yachts, and other maritime vessels.

H3: Industrial Applications

Industries that deal with water or fluids often need waterproof buttons. Whether controlling machinery or managing various processes, the reliability provided by waterproof push buttons ensures smooth operation. Find an extensive range of industrial waterproof buttons here.

H3: Outdoor Devices and Equipment

Outdoor equipment such as lawn mowers, power washers, and other garden tools often require waterproof on/off switches to handle exposure to weather elements. Waterproof buttons ensure that these devices continue to function effectively.

H2: What are the Features of Waterproof Push Buttons?

H3: Durability

Waterproof push buttons are highly durable, capable of withstanding harsh conditions without losing functionality. This makes them suitable for environments where they might be exposed to water, moisture, dust, and other potential hazards.

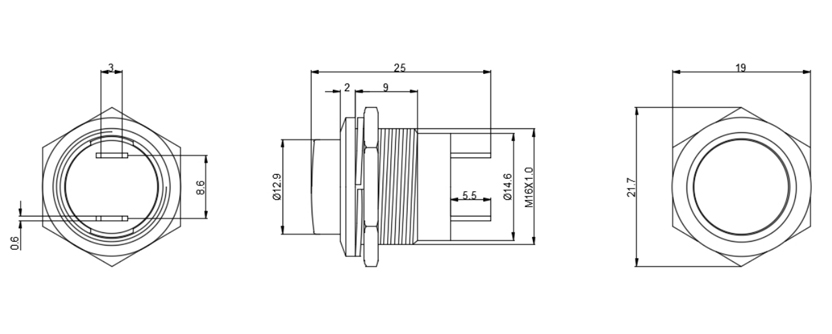

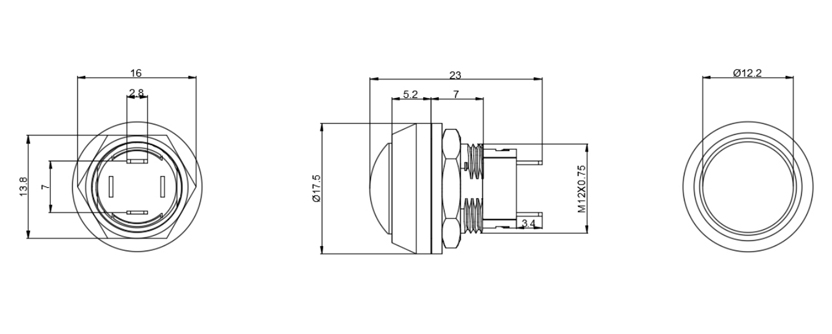

H3: Size Variations

Waterproof push buttons come in various sizes, such as 12mm, 16mm, and 30mm. For example, 12mm momentary push button switches are popular for their compact design and versatility.

H3: Design and Customization

Manufacturers offer a wide range of designs and customization options, allowing waterproof buttons to fit specific needs and aesthetics. From color variations to LED integration, the options are vast.

H2: How to Choose the Right Waterproof Push Button?

H3: Understanding the Requirements

Knowing the exact requirements of your application will guide you in choosing the right waterproof push button. Consider factors such as the button’s function (momentary or latching), size, design, and the environment where it will be used.

H3: Consulting Experts and Suppliers

Consulting with experts or suppliers can help you select the right waterproof push button for your specific needs. They can guide you based on your application’s requirements and the latest market trends. Explore various waterproof button options here.

H3: Considering the Budget

While looking for the ideal waterproof push button, it’s essential to consider the budget. There are options available at various price points, allowing for a suitable match without compromising on quality.

H2: How to Install and Maintain Waterproof Push Buttons?

H3: Installation Process

Installing waterproof push buttons is a straightforward process, but it may require specialized tools and expertise, depending on the application. Proper installation ensures optimal performance and longevity. Check out this 16mm waterproof push button switch for specific installation guidelines.

H3: Regular Maintenance

Regular maintenance of waterproof push buttons is essential to keep them functioning correctly. It includes periodic cleaning, inspections, and necessary replacements of components if needed.

H3: Safety Precautions

While handling, installing, or maintaining waterproof push buttons, following safety guidelines is crucial to avoid any accidents or damage to the equipment.

H2: Where to Buy Waterproof Push Buttons?

H3: Online Retailers

Purchasing waterproof push buttons online offers a wide variety of options and often better prices. Various suppliers provide different types, sizes, and designs, such as this extensive collection of waterproof push buttons.

H3: Local Suppliers and Manufacturers

Local suppliers and manufacturers can provide personalized service and quicker delivery. They can also offer expert guidance in selecting the right waterproof push button for your specific needs.

H3: Custom Orders

If you need waterproof push buttons with specific designs or features, you can place custom orders with manufacturers. They can create products tailored to your exact requirements, ensuring the best fit for your application.

In conclusion, waterproof push buttons are vital components in various applications, offering reliability, functionality, and aesthetics. By understanding their types, features, applications, and considering factors such as budget and expert consultation, you can find the perfect waterproof push button to meet your needs. Whether you need a waterproof latching push button switch or a waterproof momentary on-off-on toggle switch, knowing what to look for will guide you to the best solution.

H2: How to Differentiate Between Quality and Non-Quality Waterproof Push Buttons?

H3: Material Quality

The material used in waterproof push buttons significantly impacts their performance and durability. High-quality materials such as metal and durable plastic ensure that the button can withstand harsh conditions without wearing out. You can explore waterproof metal push buttons here.

H3: Waterproof Rating

A higher waterproof rating indicates better protection against water and moisture. Look for waterproof push buttons with ratings like IP65, IP67, or higher, as they provide an assurance of water resistance.

H3: Brand Reputation

Buying waterproof push buttons from reputable brands or suppliers ensures quality and reliability. They often comply with industry standards and offer warranties, reflecting confidence in their products.

H3: User Reviews and Feedback

Reading user reviews and feedback can provide insights into the actual performance and quality of the waterproof push buttons. Customers’ real-life experiences can guide you in making an informed decision.

H2: How to Troubleshoot Common Issues with Waterproof Push Buttons?

H3: Unresponsiveness

If a waterproof push button becomes unresponsive, inspect for any physical damages or debris that might be blocking its function. Cleaning and minor adjustments can often resolve this issue.

H3: Intermittent Functionality

Intermittent functionality might result from wiring problems or internal wear and tear. Checking the connections and replacing worn-out parts can restore proper function.

H3: Complete Malfunction

Complete malfunction of a waterproof push button might require professional examination. It could be due to internal failures or significant damage that might necessitate replacement with a new push button like this 24V waterproof metal push button switch.

H2: What are the Environmental Benefits of Using Waterproof Push Buttons?

H3: Longevity and Sustainability

Quality waterproof push buttons last longer and reduce the need for frequent replacements. This longevity contributes to sustainability by reducing waste and the need for new manufacturing.

H3: Energy Efficiency

Some waterproof push buttons come with energy-efficient features, such as LED indicators. These features minimize energy consumption, contributing to overall environmental conservation.

H3: Compliance with Environmental Standards

Many manufacturers adhere to environmental standards in the production of waterproof push buttons. Using such products supports eco-friendly practices and promotes responsible consumption.

H2: What Are the Innovations in Waterproof Push Button Technology?

H3: Integration with Smart Technology

Modern waterproof push buttons can be integrated with smart technology, allowing for remote control and monitoring. This innovation adds convenience and advanced functionality to various applications.

H3: Improved Aesthetics and Customization

Recent advancements in design and customization allow waterproof push buttons to be tailored to specific aesthetics and branding requirements. Check out these 16mm push button metal designs for examples of innovative aesthetics.

H3: Enhanced Safety Features

Innovations in safety features have led to waterproof push buttons that offer additional protection against electrical shocks and other potential hazards. These advancements contribute to safer and more reliable operations.

H3: Development of Specialized Buttons

Specialized waterproof push buttons such as LED 110V momentary push button switches and double push button switch 12V red green have been developed for particular needs and applications, demonstrating the continual evolution of this technology.

Waterproof push buttons continue to evolve, providing versatile and innovative solutions for various applications. Understanding the range of available options, features, benefits, and latest advancements helps consumers and professionals alike make informed decisions to suit their specific needs. From choosing the right waterproof momentary on-off-on toggle switch to maintaining and troubleshooting these essential components, a comprehensive understanding of waterproof push buttons ensures optimal performance, safety, and satisfaction. Whether you’re involved in marine, industrial, or outdoor equipment, waterproof push buttons are indispensable, and knowing how to select, install, and care for them will contribute to the success of your projects and applications.

H2: What are the Applications of Waterproof Push Buttons in Marine Environments?

H3: Control Systems

Waterproof push buttons are used in marine control systems to handle various tasks like navigation, communication, and equipment operation. They are ideal due to their resistance to salt water and extreme weather conditions.

H3: Emergency Systems

In emergency systems on ships and offshore platforms, waterproof push buttons are essential for initiating alarms, shutting down machinery, and other critical actions.

H3: Recreational Boats

Recreational boats often utilize waterproof push buttons for lighting, music systems, and other amenities. Explore marine push button switches here.

H2: How to Properly Install Waterproof Push Buttons?

H3: Selecting the Right Location

Installation starts with choosing the right location that offers protection and accessibility. Consider the surrounding environment and potential exposure to elements.

H3: Using Appropriate Mounting Hardware

Utilize appropriate mounting hardware to ensure a secure fit. It includes brackets, screws, and other components designed for waterproof installations.

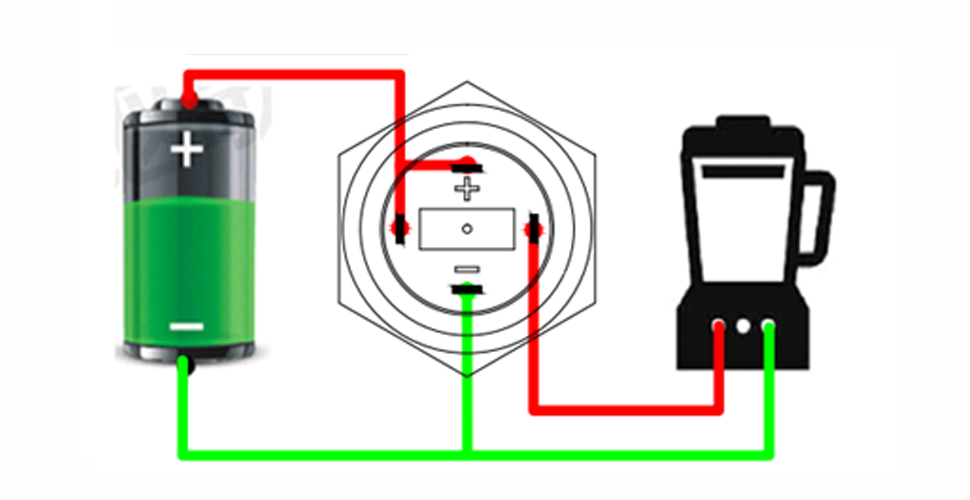

H3: Wiring and Connections

Proper wiring and connections are vital for the functioning of waterproof push buttons. Use specialized waterproof connectors and follow the wiring diagram provided by the manufacturer.

H3: Finalizing Installation with Sealing

Finalizing the installation with proper sealing ensures water and moisture don’t penetrate the assembly. Specialized gaskets and sealants can be used to enhance the waterproofing.

H2: What are the Safety Measures to Consider When Using Waterproof Push Buttons?

H3: Understanding Specifications and Ratings

Understanding the specifications and ratings of waterproof push buttons ensures their correct usage according to their design. Misuse can lead to failure or hazardous conditions.

H3: Regular Inspection and Maintenance

Regular inspection and maintenance help in identifying potential issues early and ensuring that the waterproof push buttons are in good working condition.

H3: Compliance with Safety Standards

Compliance with safety standards such as CE, UL, or RoHS is crucial. It ensures that the waterproof push buttons meet the required safety and quality benchmarks.

H2: How Can You Customize Waterproof Push Buttons for Specific Needs?

H3: Selecting Specific Features

Customizing waterproof push buttons starts with selecting specific features like size, color, shape, and function. For example, a 12mm momentary push button switch could be chosen for compact applications.

H3: Collaborating with Manufacturers

Working closely with manufacturers allows for further customization. They can provide tailored solutions, such as specialized engravings, branding, or unique functionalities.

H3: Utilizing Customizable Kits

Some suppliers offer customizable kits that allow users to assemble waterproof push buttons with desired features. These kits provide flexibility for individual or small-scale projects.

H2: Where to Buy Quality Waterproof Push Buttons?

H3: Authorized Distributors

Authorized distributors of reputable brands ensure quality and authenticity. They offer a wide range of waterproof push buttons, including 30mm waterproof push button switches.

H3: Manufacturer Direct Sales

Purchasing directly from manufacturers may offer customization options and bulk pricing benefits. Indicator Light’s push button switches provide a good example.

H3: Online Marketplaces

Online marketplaces offer a variety of waterproof push buttons from different brands and suppliers. Careful examination of reviews and ratings can guide a wise purchase.

H3: Specialty Stores

Specialty stores focusing on specific industries or applications might provide specialized waterproof push buttons suited for unique requirements.

The extensive use of waterproof push buttons across various industries and their continual innovation make them an essential component in modern applications. With proper selection, installation, and maintenance, waterproof push buttons offer reliable and efficient solutions for numerous tasks. Whether you’re looking for a waterproof button cover, waterproof latching push button switch, or a waterproof on/off switch, understanding the unique features, benefits, and applications of these buttons will guide you in making the right choice. By aligning with industry standards and embracing innovations, waterproof push buttons continue to provide versatile and robust solutions, meeting diverse needs and contributing to the successful execution of various projects.

H2: How to Test Waterproof Push Buttons for Reliability?

H3: Conducting Water Resistance Tests

Water resistance tests involve exposing the waterproof push button to controlled water exposure conditions. It ensures the integrity of the waterproofing features.

H3: Performing Mechanical Durability Tests

Mechanical durability tests involve repeated actuation to simulate real-world use. This checks how the waterproof push button withstands wear and tear.

H3: Electrical Performance Evaluation

Testing the electrical performance ensures that the waterproof push button operates within its specified electrical ratings, preventing potential malfunctions.

H3: Compliance with Industry Standards

Conducting tests in compliance with industry standards like IP ratings ensures that the waterproof push button meets the specified safety and performance criteria.

H2: What are the Latest Innovations in Waterproof Push Buttons?

H3: Smart Connectivity

The integration of smart connectivity allows waterproof push buttons to connect with smart devices or systems, providing remote control and monitoring features.

H3: Enhanced Durability Materials

Innovations in material science have led to waterproof push buttons with enhanced durability, resisting extreme temperatures and corrosive environments.

H3: Customizable Interfaces

New designs offer customizable interfaces, allowing users to change labels, colors, or functions to match specific requirements. Check out the waterproof momentary push button switch options at Indicator Light.

H3: Energy-efficient Designs

Energy-efficient designs contribute to sustainability by reducing power consumption, making waterproof push buttons more environmentally friendly.

H2: How are Waterproof Push Buttons Different from Regular Push Buttons?

H3: Enhanced Water and Dust Protection

Waterproof push buttons are specifically designed with seals and gaskets to prevent water and dust ingress, unlike regular buttons that may lack these protections.

H3: Suitable for Harsh Environments

Waterproof push buttons can be used in harsh environments, including wet, humid, or dusty conditions, where regular push buttons may fail.

H3: Material and Construction

The material and construction of waterproof push buttons are meant to endure challenging conditions. A waterproof metal push button stop switch, for example, offers ruggedness.

H3: Price Consideration

Waterproof push buttons may cost more than regular ones due to specialized materials and design. However, the investment ensures reliable performance in demanding applications.

H2: How to Select the Right Waterproof Push Button for Your Application?

H3: Determine the Requirements

Understanding the specific requirements of your application, such as current rating, voltage, mounting style, and other factors, is crucial in selection.

H3: Evaluate Environmental Conditions

Consider the environmental conditions where the waterproof push button will be used, such as humidity, temperature, and exposure to chemicals.

H3: Check Compliance and Certifications

Look for waterproof push buttons that comply with relevant certifications like IP ratings, ensuring they meet the required standards.

H3: Consider Aesthetic Preferences

Consider the aesthetic aspects like color, shape, and design, especially if the waterproof push button will be used in visible or customer-facing areas.

H3: Consult with Experts or Suppliers

Consulting with experts or suppliers can provide valuable insights and recommendations tailored to your application. Explore various waterproof push button switches here.

By understanding the variety of waterproof push buttons, their applications, and the considerations for their selection, installation, and testing, users can make informed decisions to meet their specific needs. Waterproof push buttons are versatile and robust components that find usage in various fields, including industrial machinery, marine applications, home appliances, and more. Innovations in design, materials, and functionality continue to expand their applications, making them an essential part of modern technology. Whether looking for a waterproof momentary switch normally open, a waterproof on/off switch, or a 12mm momentary push button switch, the right choice will offer reliable and efficient performance in demanding conditions, contributing to the overall success of the project or product.

H2: What Maintenance Practices Should Be Followed for Waterproof Push Buttons?

H3: Regular Inspection

Regular inspection ensures that the waterproof push buttons are free from physical damage, wear, and tear. Monitoring for signs of moisture ingress or corrosion is essential.

H3: Cleaning and Lubrication

Cleaning the waterproof push buttons with appropriate cleaning agents and applying suitable lubrication can prolong their life and maintain optimal performance.

H3: Following Manufacturer’s Guidelines

Following the manufacturer’s guidelines for maintenance ensures that the practices are aligned with the design and materials of the waterproof push buttons.

H3: Scheduled Replacement

In applications where failure is not an option, scheduling regular replacement of waterproof push buttons ensures that they are always in optimal condition.

H2: How to Troubleshoot Common Issues with Waterproof Push Buttons?

H3: Issue with Actuation

If there’s an issue with actuation, checking for physical obstructions, misalignment, or internal damage may resolve the problem.

H3: Electrical Malfunction

Electrical malfunctions can be troubleshooted by inspecting wiring, connections, and ensuring proper voltage and current supply.

H3: Water Ingress

Water ingress may indicate a failure in the waterproofing features. Inspecting seals, gaskets, and taking corrective measures can prevent further damage.

H3: Wear and Tear

Signs of wear and tear may lead to malfunction. Regular inspection and replacement of worn-out parts, as needed, can ensure ongoing reliability.

H2: How are Waterproof Push Buttons Designed for Specialized Industries?

H3: Medical Industry

In the medical industry, waterproof push buttons are designed with materials that can be easily sterilized, providing safe usage in critical medical applications.

H3: Marine Applications

Waterproof push buttons for marine applications are constructed with corrosion-resistant materials, handling saltwater exposure. Explore marine-specific options here.

H3: Food Processing Industry

In the food processing industry, waterproof push buttons must meet specific hygiene standards, using food-grade materials and designs that prevent contamination.

H3: Industrial Automation

Industrial automation requires waterproof push buttons with rugged designs to withstand heavy usage, vibration, and harsh environmental conditions.

H2: What are the Common Mistakes to Avoid When Using Waterproof Push Buttons?

H3: Incorrect Installation

Incorrect installation can compromise the waterproof features. Following the proper installation guidelines is essential.

H3: Misunderstanding of Waterproof Ratings

Misunderstanding or ignoring the specific waterproof ratings may lead to using the push button in an unsuitable environment, causing failure.

H3: Lack of Regular Maintenance

Neglecting regular maintenance can lead to hidden issues that may result in unexpected failure or decreased performance of the waterproof push buttons.

H3: Ignoring Manufacturer’s Specifications

Ignoring manufacturer’s specifications and guidelines can result in incorrect usage, affecting the functionality and reliability of the waterproof push buttons.

In the field of waterproof push buttons, careful selection, installation, and maintenance practices are vital to ensuring optimal performance and longevity. By understanding the specific requirements of various industries and applications, it becomes possible to choose and utilize the right waterproof push buttons, whether it’s a waterproof button cover, waterproof latching push button switch, waterproof on/off switch, or a waterproof momentary on-off-on toggle switch. With ongoing innovations and a focus on quality and compliance, waterproof push buttons offer an extensive array of solutions tailored to meet diverse needs and challenges. Their role in modern technology continues to expand, making them an indispensable part of various projects and products, from industrial machinery to personal gadgets. By adhering to best practices and avoiding common mistakes, users can maximize the benefits of waterproof push buttons, ensuring successful implementation and reliable functionality in various environments.

H2: How to Ensure Safety When Using Waterproof Push Buttons?

H3: Compliance with Regulations

Adhering to industry regulations and standards for waterproof push buttons ensures they meet the necessary safety criteria.

H3: Proper Installation

Proper installation by skilled professionals eliminates potential risks associated with incorrect wiring or mounting.

H3: Regular Inspection and Maintenance

Regular inspection and maintenance can identify and correct potential safety hazards before they become significant issues.

H3: Emergency Measures

Implementing emergency measures, such as emergency stop buttons or circuit breakers, provides additional safety layers.

H2: What Aesthetic Options are Available for Waterproof Push Buttons?

H3: Variety of Colors and Finishes

Waterproof push buttons come in various colors and finishes to match different aesthetic preferences and design themes.

H3: Customizable Labels and Icons

Customizable labels and icons allow for a tailored look and functionality, suiting specific applications or branding requirements.

H3: Modern and Sleek Designs

Modern and sleek designs are available, providing a contemporary appearance that can complement various design concepts. Find attractive options here.

H3: Material Choices

Material choices such as metal, plastic, or rubber offer different aesthetic and functional characteristics, enhancing the overall look and feel.

H2: How are Waterproof Push Buttons Contributing to Sustainability?

H3: Energy-efficient Models

Energy-efficient waterproof push buttons contribute to sustainability by reducing energy consumption.

H3: Recyclable Materials

Using recyclable materials in the construction of waterproof push buttons supports environmentally friendly manufacturing practices.

H3: Long-lasting Designs

Long-lasting and durable designs minimize waste by reducing the need for frequent replacements, thus contributing to sustainability.

H3: Sustainable Manufacturing Processes

Some manufacturers are adopting sustainable manufacturing processes, reducing environmental impacts in the production of waterproof push buttons.

H2: Where to Buy Waterproof Push Buttons?

H3: Direct Manufacturer Purchases

Buying directly from manufacturers like Indicator Light ensures original and quality products.

H3: Authorized Distributors and Dealers

Purchasing through authorized distributors or dealers guarantees that the waterproof push buttons are genuine and backed by warranties.

H3: Online Marketplaces

Online marketplaces offer a wide variety of waterproof push buttons, including waterproof momentary switches, waterproof on/off switches, and more.

H3: Specialty Stores

Specialty stores catering to specific industries or applications can provide expert advice and specialized waterproof push button options.

In this comprehensive overview of waterproof push buttons, we’ve explored their applications, design considerations, innovations, selection process, maintenance practices, troubleshooting tips, specialized industry designs, common mistakes to avoid, safety precautions, aesthetic options, sustainability contributions, and purchasing options. Waterproof push buttons are an essential component across a wide array of fields and continue to evolve with technological advancements, offering solutions that are as functional as they are aesthetically appealing. Whether it’s a waterproof button cover, waterproof momentary switch normally open, waterproof latching push button switch, or a 12mm momentary push button switch, understanding the characteristics, requirements, and best practices is vital to make informed decisions and ensure success in various projects and applications. By adhering to quality standards, considering sustainability, and aligning with specific needs and preferences, waterproof push buttons prove to be versatile, reliable, and indispensable in modern technology.

##Conclusion

Waterproof push buttons play a crucial role in numerous industries and applications, from industrial machinery to personal devices. They are designed to withstand varying environmental conditions, providing reliability and functionality where regular buttons might fail. The vast array of options, including waterproof button covers, waterproof momentary switches, waterproof on/off switches, and 12mm momentary push button switches, offers tailored solutions to meet diverse needs and challenges.

The careful selection, proper installation, maintenance, and understanding of waterproof push buttons’ applications ensure optimal performance and longevity. Innovations continue to enhance their aesthetic appeal and contribute to sustainability, making them a valuable choice for modern technology.

Various sources, including direct manufacturers like Indicator Light, authorized distributors, online marketplaces, and specialty stores, provide access to quality waterproof push buttons. With continuous advancements and focus on quality, safety, and compliance, waterproof push buttons are poised to remain an essential part of technology, fulfilling various requirements and exceeding expectations.

Waterproof Push Button Prices in the USA

When it comes to purchasing waterproof push buttons, it’s crucial to consider the prices offered by different suppliers. This article will provide you with an overview of the price range for waterproof push buttons in the USA, along with details from various suppliers.

Searching for Waterproof Push Button Prices

To begin your search for waterproof push button prices, you can explore different suppliers. Here are a few options to consider:

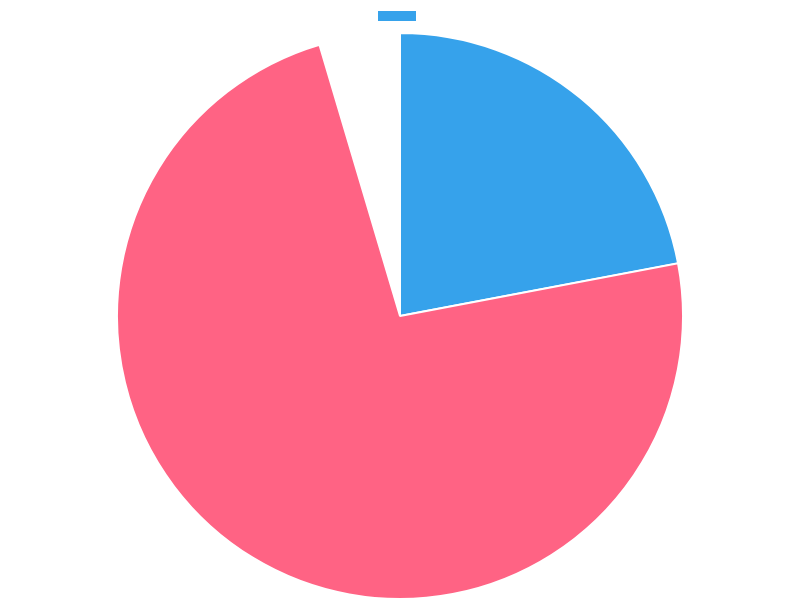

Price Range Distribution among Suppliers

Let’s take a look at the price distribution among these suppliers in the form of a pie chart:

According to the chart, the price distribution among the suppliers is as follows:

- Prowire USA: 35%

- Amazon: 50%

- STI EMEA: 15%

Price Range Details

Now, let’s delve into the specific price ranges offered by each supplier:

| Supplier | Price Range | Notes |

|---|---|---|

| Prowire USA | $15.900 to $19.950 | Depending on the model and features |

| Amazon | $5 to $20 | Depending on the model and features |

| STI EMEA | Not specified | Specific pricing information not available |

Exploring the Suppliers

Prowire USA

Prowire USA is a reliable supplier of waterproof push buttons. They offer a range of models with prices varying from $15.900 to $19.950 per unit, depending on the specific model and features.

Amazon

Amazon is a popular online marketplace that provides a wide selection of waterproof push buttons. The prices on Amazon can range from $5 to $20 or more, depending on the model and features.

STI EMEA

STI EMEA is known for their unique range of waterproof push buttons, which are highly regarded for their design, quality, and value. However, specific pricing information is not available on their website.

Important Considerations

It’s important to note that the prices mentioned above are approximate and may vary depending on the supplier, retailer, and location. To obtain the most accurate and up-to-date pricing information, it is recommended to check with the specific supplier or retailer.

In conclusion, when searching for waterproof push button prices in the USA, it’s essential to consider multiple suppliers to gain a comprehensive understanding of the market. By exploring options like Prowire USA, Amazon, and STI EMEA, you can find the right waterproof push button that suits your needs and budget.

Water in a pushbutton switch may cause the following hazards:

Electrical appliances can malfunction:

Water is a good conductive medium, and when water enters a pushbutton switch or the circuit around it, it can cause a short circuit or an electrical failure.

This can cause the pushbutton switch to not work properly, causing damage to the circuit which can lead to a serious fire.

Risk of electric shock:

If water gets into a pushbutton switch, there is a risk of electric shock when people touch the wet switch.

Electrocution is very dangerous, causing light electric shock injuries and serious life-threatening injuries.

Causes damage to equipment:

If water enters a pushbutton switch, the water may penetrate inside the switch and damage the internal mechanical or electrical components.

Eventually, the switch will not work properly and will need to be repaired or replaced after a power failure.

Causes short circuits:

When water enters the circuit, it may cause a short circuit.

A short circuit may cause excessive current, resulting in overheating of equipment, damage to parts, and in severe cases, fire.

Endangers personal safety:

When water enters a pushbutton switch, especially in a humid environment, there is a risk to personal safety.

The combination of water and electricity can easily lead to electrocution accidents and endanger our lives.

Summarize:

Therefore, in special environments, you should try to avoid water in the push button switch. So the push button switch waterproof was invented.

If you find water in the push button switch, you should immediately disconnect from the power supply and immediately seek professional help to repair the power off or replace the switch to ensure safety.

Advantages of waterproof push button switches:

What are the advantages of the waterproof button in comparison?

| Advantages | Description |

|---|---|

| Waterproof Performance | Waterproof buttons and switches have excellent waterproof performance, effectively preventing water and moisture from entering the internals, reducing the risk of electrical malfunctions. |

| Reliability | Waterproof buttons and switches are designed and tested to provide high reliability and durability, ensuring stable operation over an extended period with minimal chances of failure. |

| Safety | Waterproof buttons and switches prioritize safety, significantly reducing the risk of electric shock. Even when users have wet hands or the switch is exposed to water splashes, they offer reliable electrical isolation and protection. |

| Wide Application | Waterproof buttons and switches find applications in various fields such as outdoor appliances, bathroom equipment, boats, industrial machinery, etc., catering to diverse waterproofing needs. |

| Easy to Clean | The surface of waterproof buttons and switches is typically made of water-resistant materials, facilitating easy cleaning. They resist water droplets, dust, and dirt accumulation, ensuring a clean appearance and smooth operation. |

| Maintenance Cost Savings | Waterproof buttons and switches reduce the risk of electrical malfunctions and damage, resulting in lower maintenance costs. Their ability to prevent water ingress extends their lifespan, reducing the need for frequent replacements due to water-related damages. |

| Compliance with Standards and Certifications | Waterproof buttons and switches usually conform to relevant waterproof standards and certification requirements, ensuring recognized performance and safety, meeting specific industry and market demands. |

It is important to note that specific push button switch waterproof features and benefits may vary by manufacturer, model and application.

When purchasing, it is recommended to refer to the technical specifications and documentation provided by the manufacturer for specific waterproofing features and benefits of the product.

Two Types of Push Button Switch Waterproof

| Surface Waterproof Push Buttons Switches | Fully Waterproof Push Buttons Switches | |

|---|---|---|

| Definition | Surface waterproof pushbutton switch with an outer surface that resists water splash and light moisture. | The fully waterproof pushbutton switches are designed to withstand complete immersion in water or exposure to severe moisture without any damage. |

| Protection Level | Provides basic protection against water splashes and light moisture on the surface. | Offers comprehensive protection against water ingress and can withstand full immersion without compromising functionality. |

| Applications | Ideal for applications with occasional exposure to water or light moisture, such as kitchens, bathrooms or outdoor areas with limited direct water contact. | Ideal for high-risk applications with continuous or long-term exposure to water, such as marine environments or industrial settings. |

| Water Resistance Rating | Typically has an IP (Ingress Protection) rating of IPX4 or higher, indicating resistance to water splashes from any direction. | Has a higher IP rating of IPX7 or higher, indicating the ability to withstand immersion in water up to a certain depth for a specific duration. |

| Internal Protection | Primarily focuses on protecting the external surface against water intrusion, but internal components may not be fully sealed. | Designed with robust internal sealing to prevent water penetration, ensuring the internal components remain completely protected. |

| Maintenance | Requires regular inspection and cleaning to ensure no water has seeped into the internal components. | Requires minimal maintenance, as the comprehensive sealing prevents water ingress and minimizes the risk of internal damage. |

About this 22MM Push Button Switch Waterproof

The picture shows this is all waterproof button switch.

It is 22MM in size and is relatively suitable for some small devices that need to be waterproof.

It is fully sealed at the end, so it can be used normally even if it is placed in water.

This product has obtained the corresponding IP67 waterproof certification.

If you think its size is smaller, we also recommend an enlarged 30MM fully waterproof pushbutton switch, which is more suitable for use on large equipment and more atmospheric.

We can customize the voltage and color of the pushbutton switch.

FILN’s Push Button Switch Waterproof:

As a professional push button switch manufacturer, we can provide both surface waterproof push button switches and produce fully waterproof push button switches for you.

On top of these two, the function of the push button switch is also different, like waterproof momentary push button switch such as momentary push button, and there is a self-locking waterproof switch.

In addition, FILN’s waterproof pushbutton switches can also be equipped with lights, which are capable of emitting light.

Because LEDs are installed in the push button switch, a corresponding voltage is generated.

The general waterproof push button switch 12v momentary is more common, there is also the voltage is 220V. any button switch voltage can be produced for you.

Button Parameters

| Production Series | FLM22-FW-3 | Light Guide Button | |

| Button Shape | round | Actuator | 304 Stainless steel |

| Button LED Color | Housing Sleeve | H59 nickel plated brass/304Stainless steel | |

| Mechanical Life | The 500 thousand time | Button Pin | H62 copper alloy |

| Electrical Life | The 100 thousand time | Rubber Ring | SIL silica gel |

| Protection Level | IP65 IK08 | Nut | H59 nickel plated brass |

| Rated Voltage | 220V(AC) | Housing | PA66+GF20% nylon |

| Rated Current | 10A | Light Source | |

| Rated Power | 2200W | Resistor | Metal film |

| Operating Temperature | -25℃~+85℃ | Contact | AgCdO12 |

If you are interested in the 22MM waterproof momentary push button switch in the picture, please leave us a message directly at the bottom of the website and we will provide you with the best quotation.

If you need to purchase a lot of quantity, you can send an email directly to our sales manager, and even customize a unique pattern/logo on the waterproof ship switch for you, which can serve you one-to-one.

Waiting for your consultation.