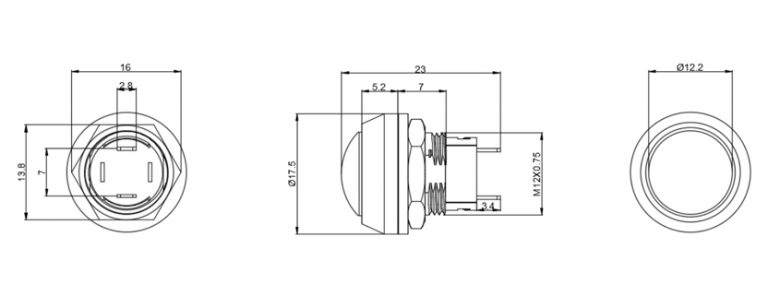

Product Drawings:

Product Parameters:

| Product Name | GQB16 |

| Operation Type | Momentary |

| Light Voltage | DC 12V |

| Contact Type | 1NO |

| Material | Plastic |

| Mounting Hole Dia. | 16mm |

| Included Components | Micro Switch (optional, not included) |

How to wire a button electric switch with led?

In electrical circuits, how you wire a button electric switch can affect not only the operation of the switch itself but also connected devices. Here, we explain two different circuit configurations for a button electric switch, focusing on LED indicators and device operation.

The wiring way is as follows, the first step, the positive pole of the power is connected to the NO pin, the second step, connect the negative pole of power to the C pin of the switch.

Video of other button switch wiring

Customization Advantages of FILN button electric switch

The FILN button electric switch is a versatile product that can be customized according to the needs of different customers. This flexibility opens up an array of advantages for users, making it a sought-after component in various applications.

Why Customization is Important for button electric switch ?

Customization is not just a luxury but a necessity in the ever-competitive market. Manufacturers are under constant pressure to provide products that meet specific customer needs. In the case of the FILN button electric switch, customization has a significant impact in terms of functionality, aesthetics, and adaptability.

- Industry requirements differ: Different sectors have different requirements for push button switches. For example, the medical industry might require switches that are easily sterilizable, while the automotive industry may need switches that can withstand harsh conditions.

- Consumer Preferences: End-users may prefer specific symbols or lights that make the switches easier to use or identify, enhancing the user experience.

- Technological Advances: As technology progresses, the requirement for switches also changes. Customization ensures that the product remains relevant.

Customizable Button Symbols

One of the most prominent features that can be customized in a FILN button electric switch is the button symbol. Customers can opt for various light symbols depending on their specific needs.

- User Experience: A customized symbol can dramatically improve user experience by providing easy identification of the button’s function.

- Branding: Companies can also opt for symbols that align with their brand identity, ensuring consistency in product design.

- Regulatory Compliance: In some industries, there are specific symbols that are required by law to ensure safety and compliance.

Customizable Voltage Options

Another crucial aspect of customization is the voltage of the push button switch. FILN offers various voltage options, such as 110v push button switches, to cater to the varied needs of customers.

- Geographic Requirements: Different countries have different standard voltages. Custom voltage options allow for the global distribution of products.

- Device Compatibility: Customizable voltage ensures that the switches can be easily integrated into different systems without requiring additional components.

- Energy Efficiency: The ability to customize voltage can help in creating energy-efficient systems.

FILN’s commitment to customization offers not just product variety but also competitive advantage. Whether it’s custom symbols, voltages, or connectors, the button electric switch can be tailored to meet the unique demands of your project, making it a smart choice for a multitude of applications.

Related products:

What is a Button Electric Switch and How Does it Work?

A button electric switch is a type of switch mechanism that controls the flow of electricity by opening or closing an electrical circuit. Primarily used in a range of residential, commercial, and industrial settings, button electric switches are a key component in managing electrical power.

Mechanical Principles: The switch consists of a housing containing mechanical contacts that complete or break the circuit when the button is pressed or released.

Electrical Components: Internally, button electric switches usually contain contacts, a spring, and a button actuator. The spring mechanism helps to revert the button to its original position after being pressed.

Application: They are frequently used for operations like turning lights on/off, initiating electrical circuits, and in control panels.

Types: Button switches come in various forms, including but not limited to, momentary, latching, single-pole, and double-pole.

Compatibility: These switches are compatible with different voltage and current ratings, making them versatile for various applications.

Size and Material: They are generally small in size and may be made from plastic or metal. Some come with LED indicators.

Wiring: Wiring a button electric switch requires some knowledge of electrical circuits. For comprehensive guidance on wiring, visit How to wire a push-button switch.

Durability: High-quality button switches are designed for longevity and can withstand a substantial number of press/release cycles.

Safety: It’s essential to follow safety procedures while installing or using button electric switches to avoid electrical shocks.

Replacement: Switches may wear out over time and may need replacement, especially in older installations.

How Do You Choose the Right Button Electric Switch?

When choosing a button electric switch, several factors come into play:

Application Requirements: Know the specific application you need the switch for. For example, a heavy-duty industrial setting might require a different type of switch compared to a residential light switch.

Voltage and Current: Always match the switch to the voltage and current specifications of the electrical circuit it will control.

Type of Switch: There are several types, like momentary or latching. Momentary switches return to their default position after being released, while latching switches stay in the new position until pressed again.

Material and Durability: Choose a switch made from materials that are suitable for your application. Durability is especially important for switches that will be used frequently.

Safety Features: Look for safety certifications and features like water-resistance if the switch will be used in an environment exposed to moisture.

Installation: Some switches are easy to install yourself, while others may require professional installation. Always refer to the manufacturer’s guidelines.

Price: Switches come in a variety of price ranges. It’s important to balance cost with quality and functionality.

Local Codes and Regulations: Always make sure the switch you’re installing meets all local and national electrical codes.

Reviews and Recommendations: It’s always a good idea to look at product reviews and ask for recommendations from people in the same industry.

Retailer or Manufacturer: Finally, choose a reliable retailer or manufacturer to ensure you’re getting a high-quality product.

For a detailed guide on how to connect a button electric switch, you can refer to How to connect a push-button switch.

What are the Common Uses of Button Electric Switches?

Button electric switches are versatile and find applications in a wide array of areas:

Household Applications: One of the most common uses is in household lighting. From push button light switch replacement to installation, they’re ubiquitous in homes.

Industrial Use: In industrial settings, these switches are often part of complex control systems and may be used to initiate a wide range of processes.

Automotive Industry: In the automotive sector, button switches are used for various functions including ignition, window control, and entertainment systems.

Consumer Electronics: In gadgets like smartphones, cameras, and household appliances, micro button switches are commonly used.

Medical Equipment: In medical devices, button switches are used to control various functionalities and need to be highly reliable.

Gaming Consoles: These switches find application in gaming consoles, where quick and reliable button presses are critical.

Public Services: In public transport services, button switches are used for various controls, including door operation and emergency systems.

Accessibility: Button switches are also employed in systems designed for individuals with mobility challenges.

Security Systems: These switches are often part of home and industrial security systems, used for tasks like arming or disarming alarms.

Control Panels: Often used in control panels in both residential and commercial settings for a variety of applications.

For specific use-cases in wiring a button electric switch with an LED, you can check out How to wire push button switch with LED.

What are the Types of Button Electric Switches?

There are numerous types of button electric switches available, each with unique features to suit various applications:

Momentary Switches: These switches revert to their default position after being pressed and released. They are commonly used in applications like doorbells.

Latching Switches: Once pressed, these switches latch into a new position and stay that way until pressed again. These are often used in lighting systems.

Single-Pole Switches: These have one input and one output and are often used for simple on/off functions.

Double-Pole Switches: These have two inputs and two outputs, offering more complex control.

Illuminated Switches: These switches come with a built-in LED to indicate their status.

Non-Illuminated Switches: These are standard switches without an LED indicator. For more details, you can visit Non-Illuminated Push Button Power Switch.

Waterproof Switches: These are designed to operate reliably in wet conditions. Check out Push Button Switch Waterproof for more information.

High-Voltage Switches: These are designed for use in high-voltage applications.

Low-Voltage Switches: These are meant for use in low-voltage applications like in some types of battery-operated devices.

Custom Switches: These are tailor-made to suit specific needs and are often used in specialized industrial applications.

How to Install a Button Electric Switch?

Installing a button electric switch requires caution and a certain level of expertise. Here are the general steps involved:

Safety First: Turn off the power to the circuit you’ll be working on to ensure safety.

Preparation: Make sure you have all the necessary tools and materials, including the switch, wire, screwdriver, and wire stripper.

Identify Wires: Identify the hot wire, ground wire, and any neutral wires in the circuit.

Connect Wires: Using the identified wires, connect them to the corresponding terminals on the switch. For a momentary car push button ignition switch, refer to Momentary Car Push Button Ignition Switch.

Secure the Connections: Use wire nuts or terminal screws to secure the wire connections.

Test: Before securing the switch to the wall or panel, turn the power back on briefly to test the switch. If it works as expected, turn the power off again.

Secure the Switch: Once you’ve verified that the switch is working correctly, you can secure it to the wall or panel.

Replace the Faceplate: Attach the switch cover or faceplate over the switch.

Final Testing: Turn the power back on and test the switch one more time to make sure it’s functioning correctly.

Documentation: Keep a record of the installation, especially if it’s part of a more complex electrical system.

How to Maintain a Button Electric Switch?

Maintenance is key for the longevity and reliability of any button electric switch:

Regular Checks: Make a habit of inspecting the switch and surrounding wiring regularly for any signs of wear or damage.

Cleaning: Clean the exterior of the switch as needed, using materials that won’t harm its surface.

Replacement: When you notice signs of wear or if the switch starts to malfunction, it’s often better to replace it than to try and repair it. For a variety of push button switches, check out Push Button Switch On-Off.

Consult a Professional: For more complex systems, consult a professional for regular maintenance checks.

Follow Manufacturer Guidelines: Always refer to the manufacturer’s guidelines for specific maintenance procedures.

What are the Historical Developments in Button Electric Switches?

Push button light switch history reveals a series of developments that have made them more efficient, reliable, and versatile. Initially, switches were bulky and not very user-friendly. Over time, they evolved to become smaller, more efficient, and easier to use.

Early Designs: The earliest designs were basic and merely served the purpose of breaking or completing a circuit.

Material Evolution: Over the years, different materials like plastics and advanced alloys started being used, making switches more durable and reliable.

Technological Advancements: With technological growth, switches started coming with features like LED indicators, waterproofing, and even touch sensitivity.

Safety Improvements: Significant improvements in safety standards have led to switches that are safer to use and install.

Miniaturization: In line with general trends in electronics, switches have also become much smaller, making them suitable for a range of new applications.

Smart Switches: With the advent of smart home technologies, button electric switches are now also available with remote control capabilities via smartphones.

What are Common Problems and Their Solutions?

Button electric switches are generally reliable, but they can face some common issues:

Intermittent Operation: If the switch works intermittently, the internal contacts might be worn or corroded. Replacement is often the best solution.

No Operation: If pressing the button doesn’t complete the circuit, the internal mechanism might be broken. A replacement is usually required.

Stuck Button: If the button doesn’t return to its default position, the spring mechanism inside could be damaged. The switch will need to be replaced.

Electric Shock: If you feel a shock when touching the switch, this is a serious issue and should be addressed immediately by a professional.

Faulty Wiring: Sometimes the issue isn’t with the switch but the wiring. In such cases, consult a professional.

For in-depth information on how push-button switches are wired, visit How is the push-button switch wired?.

What Are the Popular Brands of Button Electric Switches?

When it comes to button electric switches, several brands have carved a niche for themselves in the market:

Siemens: Known for their high-quality and durable products, Siemens offers a wide range of button electric switches suitable for both industrial and residential purposes.

Schneider Electric: Their switches are widely used and respected for their reliability and range of features.

Omron: Specializing in automation and control systems, Omron offers switches designed for specialized applications.

Honeywell: Their switches are known for their durability and are commonly used in industrial settings.

Eaton: They offer a wide range of switches including heavy-duty industrial switches.

For those who are interested in different options for a push-button switch, you can explore the category page for push-button switches.

How to Choose the Right Button Electric Switch?

Choosing the right button electric switch depends on a number of factors:

Application: Understanding the application where the switch will be used is crucial. Is it for a home, an industrial setting, or a specialized piece of equipment?

Type of Switch: Decide on the type of switch you need, be it a momentary, latching, or any other type.

Voltage and Current Ratings: Make sure to pick a switch that can handle the voltage and current requirements of your application.

Material: Different applications may require switches made of specific materials for durability, safety, or resistance to environmental conditions.

Extra Features: Consider if you need any extra features like illumination, waterproofing, or specialized markings on the switch.

For guidance on the technical aspects, you can read How to Connect a Push Button Switch.

Are Button Electric Switches Safe for Home Use?

Safety is a primary concern when using button electric switches in a residential setting:

Certification: Always choose switches that have been certified by recognized safety organizations like UL or CE.

Installation: Proper installation by a qualified electrician minimizes risks. Improper installation can lead to hazards such as electric shocks or fires.

Child Safety: If you have children, consider switches that come with child safety features to prevent accidental operation.

Quality: Don’t compromise on quality to save a few bucks. Low-quality switches are more likely to malfunction and can pose safety risks.

Periodic Checks: Regular maintenance and inspections can help identify any issues before they become a problem.

For an extra layer of safety, especially for specific types of switches, consider browsing Push Button Machine Switch.

Can Button Electric Switches be Used for Heavy Machinery?

Using button electric switches for heavy machinery comes with its own set of considerations:

Durability: Switches used in heavy machinery should be extremely durable and able to withstand the harsh conditions.

High Ratings: Such switches must have high voltage and current ratings to handle the load.

Safety Features: Due to the potentially dangerous nature of heavy machinery, safety features like emergency stop buttons are often necessary.

Ease of Use: The switches should be easy to operate even with gloves on, as is often required in industrial settings.

Documentation: Ensure proper documentation for setup, usage, and emergency procedures to minimize risks.

What Are the Environmental Considerations for Button Electric Switches?

Environmental considerations are increasingly important when selecting and using button electric switches:

Energy Efficiency: Opt for switches that help in conserving energy, especially in large setups where multiple switches are used.

Material Sustainability: Consider switches made from materials that are recyclable or biodegradable.

Longevity: Longer-lasting switches require fewer replacements, reducing waste.

Resistance: In certain environments, like outdoors or in industrial settings, opt for switches that are resistant to elements like water and dust.

For outdoor and tough environmental conditions, take a look at 12V Push Button Switch.

Conclusion

Choosing, installing, and maintaining button electric switches require careful consideration of numerous factors. From the type of switch suitable for your application to the importance of safety features and regular maintenance, making an informed decision will ensure that you get the most out of your button electric switches.