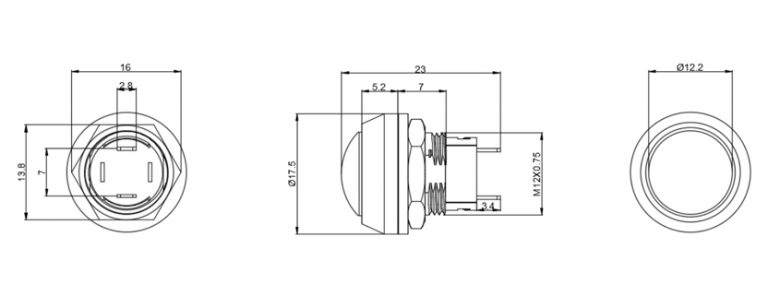

Product Drawings:

Comprehensive Guide to Stainless Steel Push Buttons: Applications, Features, and Selection

- Name:stainless steel push buttons

- Model:GQB12

- Head Type:Hight Head

- Mounting Size:12MM

- Switching Functions:Momentary

- Contact Configuration:1NO

- Rated Voltage: 3A DC / 3A AC

- Voltage Options:36V (DC)250V (AC)

- Material:ABS plastic, Plastic

- Download Certification:CE, CCC, ROSH, UL

- Email:inquiry@cnylin.com.cn

Product Parameters:

| Production Series | FL-GQB12 | Light guide Button | |

| Button Shape | round | Mounting Hole Dia | 12mm |

| Button Color | Housing Sleeve | ABS plastic | |

| Mechanical Life | The 500 thousand time | Button Pin | |

| Electrical Life | The 100 thousand time | Rubber Ring | SIL silica gel |

| Protection Level | IP65 | Nut | H59 nickel plated brass |

| Rated Voltage | 36V (DC)

250V (AC) |

Housing | ABS plastic |

| Rated Current | 3A DC / 3A AC | Light Source | |

| Rated Power | 36W(DC)125W(AC) | Resistor | |

| Operating Temperature | -25℃~+85℃ | Contact | AgCdO12 |

How to wire a stainless steel push buttons with led?

In electrical circuits, how you wire a stainless steel push buttons can affect not only the operation of the switch itself but also connected devices. Here, we explain two different circuit configurations for a stainless steel push buttons, focusing on LED indicators and device operation.

The wiring way is as follows, the first step, the positive pole of the power is connected to the NO pin, the second step, connect the negative pole of power to the C pin of the switch.

Video of other button switch wiring

Customization Advantages of FILN stainless steel push buttons

The FILN stainless steel push buttons is a versatile product that can be customized according to the needs of different customers. This flexibility opens up an array of advantages for users, making it a sought-after component in various applications.

Why Customization is Important for stainless steel push buttons ?

Customization is not just a luxury but a necessity in the ever-competitive market. Manufacturers are under constant pressure to provide products that meet specific customer needs. In the case of the FILN stainless steel push buttons, customization has a significant impact in terms of functionality, aesthetics, and adaptability.

- Industry requirements differ: Different sectors have different requirements for push button switches. For example, the medical industry might require switches that are easily sterilizable, while the automotive industry may need switches that can withstand harsh conditions.

- Consumer Preferences: End-users may prefer specific symbols or lights that make the switches easier to use or identify, enhancing the user experience.

- Technological Advances: As technology progresses, the requirement for switches also changes. Customization ensures that the product remains relevant.

Customizable Button Symbols

One of the most prominent features that can be customized in a FILN stainless steel push buttons is the button symbol. Customers can opt for various light symbols depending on their specific needs.

- User Experience: A customized symbol can dramatically improve user experience by providing easy identification of the button’s function.

- Branding: Companies can also opt for symbols that align with their brand identity, ensuring consistency in product design.

- Regulatory Compliance: In some industries, there are specific symbols that are required by law to ensure safety and compliance.

Customizable Voltage Options

Another crucial aspect of customization is the voltage of the push button switch. FILN offers various voltage options, such as 110v push button switches, to cater to the varied needs of customers.

- Geographic Requirements: Different countries have different standard voltages. Custom voltage options allow for the global distribution of products.

- Device Compatibility: Customizable voltage ensures that the switches can be easily integrated into different systems without requiring additional components.

- Energy Efficiency: The ability to customize voltage can help in creating energy-efficient systems.

FILN’s commitment to customization offers not just product variety but also competitive advantage. Whether it’s custom symbols, voltages, or connectors, the stainless steel push buttons can be tailored to meet the unique demands of your project, making it a smart choice for a multitude of applications.

Related products:

Stainless steel push buttons are an essential element in modern industries, offering versatility and functionality in various applications. From clothing to heavy machinery, these push buttons play a crucial role. This comprehensive guide will delve into the types of stainless steel push buttons, their applications, benefits, buying guides, and more. If you’re looking to explore the world of metal push button clothing or industrial-grade stainless steel push-button switch options, this article will provide you with all the insights you need to make an informed decision. Whether you’re a novice or a seasoned professional, this guide will equip you with the knowledge to understand, choose, and use stainless steel push buttons effectively.

Table of Contents

What Are Stainless Steel Push Buttons and Where Are They Used?

Stainless steel push buttons are specially designed switches made of 304 stainless steel, known for their durability and resistance to environmental factors. These push buttons find wide applications in various industries. Here’s a detailed insight into their applications and features.

Industrial Applications

Stainless steel push buttons are predominantly used in:

- Machinery Controls: They provide precise control in various machinery applications.

- Medical Equipment: Known for their waterproof capabilities, they are perfect for medical devices.

- Automotive Controls: These buttons are used in various automotive control systems.

- Home Appliances: Being robust, they are also found in household appliances like microwaves.

For more specific details, visit Indicator Light’s Stainless Steel Push Button Switches.

Features of Stainless Steel Push Buttons

- Durability: Made with 304 stainless steel, these buttons are highly durable.

- Water Resistance: Many of them are designed as waterproof momentary switches, suitable for various applications.

- Customizable: They can be customized according to different requirements.

- Aesthetic Appeal: With a sleek design, they add to the aesthetic value of the application.

- Low Profile Options: Stainless Steel Push Button Switch Low Profile options are available for specific needs.

Check out more about 16mm Waterproof Push Button Switches for specific waterproof solutions.

How to Choose the Right Stainless Steel Push Button Switch?

Selecting the correct stainless steel push button requires consideration of various factors such as the environment, required functionality, and appearance. Here’s a comprehensive guide:

Consider the Environment

- Outdoor vs. Indoor: Consider whether the push button will be used outdoors or indoors.

- Water Exposure: For water-exposed applications, waterproof momentary push-button switches like those found at this link are suitable.

- Temperature Range: Stainless steel push buttons can withstand various temperature ranges.

Functionality Requirements

- Momentary vs. Latching: Decide whether a momentary or latching function is required.

- Electrical Ratings: Consider the electrical ratings to match the application’s requirements.

- Size: Options like 12mm or 19mm sizes, available at here, must be considered.

Aesthetic Preferences

- Color: Many stainless steel push buttons come in various colors.

- Shape: They are available in different shapes like round or flat head metal push buttons. Learn more about Flat Head Metal Push Button.

- LED Options: Some come with integrated LEDs, such as the 19mm Red LED Marine Push Button Switch.

How to Install and Maintain Stainless Steel Push Buttons?

Installing and maintaining stainless steel push buttons require careful attention to details, such as wiring and regular checks.

Installation Guide

- Check Specifications: Ensure the specifications match the application needs.

- Wiring: Proper wiring according to the provided schematics is essential.

- Mounting: Depending on the design, the mounting process can vary.

- Testing: Test the push button to make sure it’s functioning correctly.

Here’s a link to Metal Momentary Push Button installation.

Maintenance Tips

- Regular Inspection: Regularly inspect for any signs of wear or malfunction.

- Cleaning: Proper cleaning using the right agents ensures long life.

- Replacement: Knowing when to replace the push button is crucial. Consider options like 24V Waterproof Metal Push Button Switch for replacements.

How to Customize Stainless Steel Push Buttons?

Customizing stainless steel push buttons involves selecting the right size, color, function, and other features.

Size Selection

- Diameter Options: Available in various diameters, like 12mm or 19mm. Visit 19mm Momentary Push Button Lamp Switch for specific sizes.

- Height Preferences: The height can be customized according to the application.

- Low Profile Options: Low profile options are available for specific design needs.

Color and Function Customization

- Color Choices: Various color options are available to match the aesthetic requirements.

- Functionality Choices: Functions like momentary or latching can be customized.

Explore more about custom options at Push Button Switch Waterproof.

Integration with Other Components

- LED Integration: LEDs can be integrated for visual feedback.

- Engravings: Custom engravings are possible on the buttons.

- Combinations with Other Materials: Metal buzzer combinations and others can be found at Metal Buzzer.

What Are the Regulations and Certifications for Stainless Steel Push Buttons?

Understanding the regulations and certifications is essential when choosing stainless steel push buttons for your applications.

International Standards

- CE Certification: Many stainless steel push buttons are CE certified.

- RoHS Compliance: Compliance with RoHS standards ensures that the push buttons are free of hazardous substances.

- IP Ratings: IP ratings like IP67 indicate the waterproof capabilities of the push buttons.

For a broad selection, visit Indicator Light’s category page.

Local Regulations

- Compliance with Local Laws: Understanding and complying with local laws is crucial.

- Inspections and Approvals: Regular inspections and approvals by local authorities may be required.

- Industry-Specific Regulations: Different industries may have unique regulations for push buttons.

Where to Buy Stainless Steel Push Buttons?

Finding the right supplier for stainless steel push buttons requires careful consideration of factors like quality, pricing, and support.

Online Suppliers

- Websites: Many websites specialize in stainless steel push buttons like Indicator Light.

- Marketplaces: Online marketplaces also offer various options.

- Check Reviews: Checking customer reviews can provide insights into the quality and reliability.

Offline Suppliers

- Local Distributors: Many local distributors provide these push buttons.

- Manufacturer Direct: Buying directly from the manufacturer might offer better pricing and customization options

.

- Trade Shows: Visiting trade shows can provide an opportunity to see the products firsthand and negotiate with suppliers.

For more specific waterproof options, explore Waterproof Metal Push Button Stop Switch.

Consider Support and Warranty

- Customer Support: Good customer support is vital for a smooth purchase experience.

- Warranty Options: Understanding the warranty options can save future hassles.

- Return Policies: Knowing the return policies can protect against unsatisfactory purchases.

Visit Metal Rotary Switch for rotary switch options, and Metal 12V Buzzer for buzzer options.

Conclusion

Stainless steel push buttons are versatile components used in a multitude of applications. With features like water resistance, durability, and customization options, they meet the needs of various industries. Careful selection, proper installation, adherence to regulations, and knowing where to buy these push buttons can lead to successful utilization of these vital components. Whether you’re seeking a metal push button for clothing or a metal push button switch for industrial machinery, understanding the intricacies can significantly aid your decision-making process.