Small LED Indicator Lights: A Comprehensive Guide

LED indicator lights are an essential aspect of modern technology, finding applications across diverse fields such as industry, transportation, and healthcare. This article delves into the intricate details of LED indicator lights, exploring everything from global market trends, factors to consider when choosing these lights, their application in various sectors, to the advantages, disadvantages, and the technical workings of LED technology. Whether you’re a professional in the field, a hobbyist, or simply curious about this pervasive technology, this comprehensive guide offers valuable insights into the world of 8mm 12v vending blue led indicator light and other LED indicator lights. Continue reading to unveil the fascinating world of LEDs and how they are shaping the way we live and work.

What are small led indicator lights, and what are their applications?

Introduction to Small LED Indicator Lights

Small LED indicator lights, also known as Miniature Flush Indicator Lights, are compact electronic visual indicators that use light-emitting diodes (LEDs) to signal specific conditions. These lights can be found in various voltage options, including 220v, 12 volts, 120v, and 24v, and are utilized in numerous applications.

Common Applications

- Automotive Use: They are commonly used as led indicator lights for cars, signaling turn signals, brake warnings, or other status indicators.

- Industrial Machinery: In industrial settings, small led indicator lights, such as 120v led panel indicator lights, inform operators of machinery status.

- Household Appliances: Appliances like ovens, washers, and meat grinders might utilize 8mm 110v metal blue meat grinder indicator lights for indication purposes.

Technical Specifications

LED indicator lights come in various specifications, such as the 8mm high-pressure led indicator light 120v. They are available in different colors, shapes, and sizes, and some are designed for specific applications like IP67 protection or for bikes, like the 8mm IP65 12-volt indicator light for bikes.

Environmental Benefits

Small LED indicator lights are energy-efficient, offering an eco-friendly alternative to traditional bulbs. They have a longer lifespan, consume less power, and are mercury-free.

Safety Considerations

When choosing led indicator lights, considerations like voltage compatibility (e.g., led indicator light 220v) and protection level (e.g., IP67) should be taken into account to ensure safety and functionality.

Global Market Trends

The demand for small led indicator lights is growing across various industries. From automotive to consumer electronics, the trend of miniaturization and energy efficiency is driving the market.

DIY and Customization

For hobbyists and DIY enthusiasts, small led indicator lights offer a world of customization. Products like 8mm 12v vending blue led indicator light can be tailored to specific projects.

Legal Regulations

Different countries have specific regulations governing the use and manufacturing of small led indicator lights. Compliance with these standards ensures quality and safety.

Conclusion on Small LED Indicator Lights

Small LED indicator lights serve various purposes across different domains. Their adaptability, energy efficiency, and customization possibilities make them indispensable in modern applications.

How do 12 volt led indicator lights differ from other voltages?

Overview of 12 Volt LED Indicator Lights

12 volt led indicator lights are designed to operate at a voltage of 12V. They are prevalent in automotive applications, where 12V is a standard voltage. These lights are compatible with many vehicles, including motorcycles, and are available at various online stores, like here.

Comparison with Other Voltages

- 220V LED Indicator Lights: Unlike the 12 volt version, 220V indicator lights are used in industrial or high-power applications. More details on led indicator light 220v can be found online.

- 120V LED Indicator Lights: 120V is typically used in domestic appliances and commercial machinery, like 120v led panel indicator lights.

- 24V LED Indicator Lights: These are often found in commercial vehicles and specific industrial machinery.

Advantages of 12 Volt LED Indicator Lights

12 volt led indicator lights have specific benefits:

- Compatibility with automotive systems.

- Energy efficiency, especially compared to traditional bulbs.

- Availability in various designs like 8mm mini IP67 277v indicator light.

Challenges with 12 Volt LED Indicator Lights

Despite the advantages, there might be challenges such as:

- Voltage compatibility issues with non-12V systems.

- Possible need for voltage regulators or converters for specific applications.

Usage in Various Industries

12 volt led indicator lights are versatile:

- Automotive: Used as dashboard indicators or exterior signal lights in cars, motorcycles, etc.

- Marine: Used in boats for navigation or status indication.

- Consumer Electronics: Used in devices requiring 12V power.

Customization and DIY Opportunities

12 volt led indicator lights are popular among hobbyists for customization, and there are options like 8mm 12v led green indicator light for specific needs.

Environmental Considerations

Like other small LED indicator lights, 12-volt versions are also environmentally friendly, consuming less power and lasting longer.

Global Market Presence

The market for 12 volt led indicator lights continues to grow, especially in the automotive sector, where fuel efficiency and sustainability are key concerns.

Conclusion on 12 Volt LED Indicator Lights

12 volt led indicator lights offer specialized applications in automotive and other industries. Their energy efficiency, compatibility, and customization options contribute to their growing demand.

What is the meaning behind different LED indicator colors?

Understanding LED Indicator Colors

The color of LED indicators often conveys specific information. For example, green may signify “go” or “operational,” red might indicate a warning or error, and blue could represent connectivity or cooling.

Common LED Indicator Colors and Meanings

- Green: Generally means operational or ready status. It’s often used in traffic lights and control panels.

- Red: Usually indicates a warning or error. You can find 12v red mini led indicator lamp light in various applications.

- Blue: Often associated with connectivity, cooling, or specific conditions, like flat head mini blue led indicator light.

- Yellow/Amber: Signifies caution or transitional states in systems.

Industry-Specific Color Codes

Different industries may have unique color coding systems. For example:

- Healthcare: Specific colors might represent different alert levels.

- Automotive: Colors signify various functionslike turn signals, high beams, etc.

Customization of Colors

Many LED indicator lights allow color customization, like 8mm custom 110v IP67 oven indicator lights, to match specific requirements or branding.

Regulations and Standards

Certain industries have regulations on the use of specific colors for safety and standardization. Compliance with these norms is essential.

Technological Advancements

Modern LED technology enables more precise color rendering, allowing for a broader range of applications, including multi-color indicators like 6v double color led indicator light.

Psychological Aspects

Colors in LED indicators can evoke specific psychological responses. For instance, red can grab attention, while green often conveys safety.

Environmental Considerations

The manufacturing process of specific color LEDs might have varying environmental impacts. Considering eco-friendly options is beneficial.

Global Trends

The global trend towards customization and specificity in product design is driving the use of different colored LED indicators.

Conclusion on LED Indicator Colors

The meaning behind LED indicator colors is multifaceted, encompassing psychological, regulatory, and functional aspects. Different colors convey different information, and understanding these can enhance usability and efficiency.

What are the characteristics of LED panel indicator lights?

Definition and Use of LED Panel Indicator Lights

LED panel indicator lights are small LED lights embedded into panels to provide visual indications. They are used in a variety of settings, from industrial control panels to household appliances.

Types of LED Panel Indicator Lights

- Voltage-Based: Different voltage options like 120v led panel indicator lights are available. More on 120v led panel indicator lights can be found online.

- Shape and Size: They come in various shapes and sizes, such as converx head 8mm mini led indicator lights.

- Color Options: LED panel lights can be found in different colors to signify various statuses.

Advantages of LED Panel Indicator Lights

The benefits of using LED panel indicator lights include:

Challenges with LED Panel Indicator Lights

Some challenges might include:

- Compatibility with existing systems.

- Possible higher upfront cost compared to traditional bulbs.

Industry Applications

LED panel indicator lights find use in:

- Industrial Control Panels: To indicate machinery status.

- Home Appliances: In washing machines, ovens, etc.

- Medical Equipment: To signal various operational statuses.

Customization Options

Customization in size, color, voltage, such as 8mm led metal 110v yellow indicator light, is available to suit specific requirements.

Compliance and Regulations

Compliance with industry standards and regulations ensures the quality and safety of LED panel indicator lights.

Technological Advancements

New technologies enable more functionalities in LED panel indicator lights, such as brightness control or multi-color indications.

Environmental Benefits

LED panel indicator lights are more eco-friendly compared to traditional incandescent bulbs, contributing to sustainability goals.

Market Trends

The market trend towards automation and digitization in various industries is driving the demand for advanced LED panel indicator lights.

Conclusion on LED Panel Indicator Lights

LED panel indicator lights are versatile, energy-efficient, and customizable, suiting a wide range of applications. Understanding their characteristics helps in choosing the right product for specific needs.

How can you choose the best LED indicator lights for cars?

Introduction to LED Indicator Lights for Cars

LED indicator lights for cars are crucial components that provide visual signals for various functions like turning, braking, or alerts. Choosing the right ones is essential for safety and aesthetics.

Factors to Consider While Choosing

- Compatibility: Ensure the LED lights are compatible with your car model and system.

- Voltage Requirements: Choose the right voltage, like 12 volts led indicator lights.

- Color Preferences: Different colors can be chosen for different functions.

Advantages of LED Indicator Lights for Cars

LED lights for cars offer benefits such as:

Challenges in Selection

Challenges might include:

- Finding compatible lights for specific car models.

- Navigating regulatory compliance for road safety.

Customization Options

Customized LED indicator lights can enhance the car’s appearance and functionality. You can find various options like 8mm red flashing led indicator light for specific needs.

Legal Compliance

Adhering to legal standards for brightness, color, and positioning is vital to ensure road safety.

Environmental Impact

Choosing eco-friendly LED indicator lights contributes to environmental sustainability.

Global Trends in Automotive LED Lights

Trends like smart lighting and customization

are influencing the automotive LED light market.

Conclusion on LED Indicator Lights for Cars

Choosing the best LED indicator lights for cars involves considering compatibility, aesthetics, legal compliance, and environmental impact. The right selection enhances safety and adds a personal touch to the vehicle.

What are the applications and specifications of 120v led indicator light circuit?

Introduction to 120v LED Indicator Light Circuit

120v led indicator light circuits are commonly used in North America for various applications. They consist of a 120v power source connected to an LED indicator light.

Applications of 120v LED Indicator Light Circuit

These circuits are used in:

- Industrial Controls: To show machinery status.

- Home Appliances: To signal operational modes.

- Public Spaces: For emergency lighting or informational signage.

Specifications of 120v LED Indicator Light Circuit

- Voltage Rating: 120v.

- Current Requirements: Typically low, depending on the LED.

- Color Options: Available in various colors.

- Mounting Options: Can be panel-mounted like 8mm high-pressure led indicator light 120v.

Advantages of 120v LED Indicator Light Circuit

Advantages include:

- Compatibility with the standard North American power supply.

- Energy efficiency.

- Versatility in applications.

Challenges in Using 120v LED Indicator Light Circuit

Challenges might include:

- Ensuring proper voltage regulation.

- Compatibility with existing systems.

Customization Possibilities

Customization in color, mounting, brightness is possible, including 8mm 110v metal blue meat grinder indicator light.

Compliance with Standards

Meeting the necessary electrical standards and regulations ensures safety and reliability.

Technological Innovations

Innovations in LED technology allow for more functionalities in 120v led indicator light circuits, such as dimming or flashing.

Environmental Considerations

Using LED over traditional bulbs reduces energy consumption, aligning with sustainability goals.

Market Trends

The trend towards energy efficiency and smart controls is driving the use of 120v led indicator light circuits in various applications.

Conclusion on 120v LED Indicator Light Circuit

The 120v led indicator light circuit offers a versatile and energy-efficient solution for various applications. Understanding its specifications and potentials enables optimal utilization.

How are 24v led indicator lights manufactured?

Introduction to 24v LED Indicator Light Manufacturing

24v LED indicator lights are widely used in various applications like industrial controls or vehicles. The manufacturing process is intricate, involving several stages.

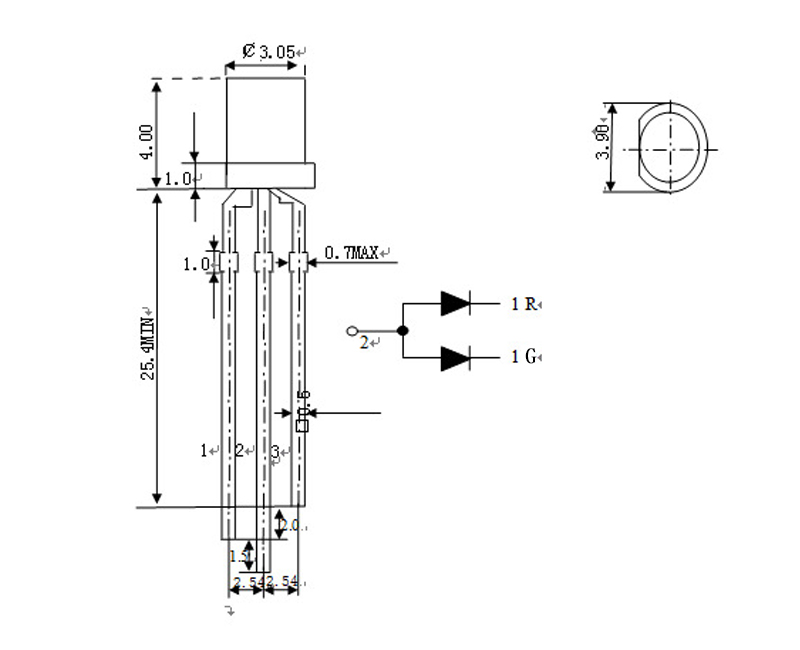

Stages of Manufacturing 24v LED Indicator Lights

- Designing: Creating specifications and blueprints.

- Material Selection: Choosing suitable materials for different parts.

- Assembling Components: Putting together different parts.

- Testing: Ensuring the lights meet the required standards like 8mm IP65 12 volt indicator light for bike.

- Packaging: Packaging the final product for distribution.

Materials Used in Manufacturing

Different materials are used for various parts:

- LED Chip: The light-emitting diode itself.

- Housing: Materials like metal or plastic.

- Electrical Components: Wires, resistors, etc.

Technology and Machinery

Advanced technology and machinery are used for:

- Precision in assembly.

- Quality control.

- Efficient production.

Quality Control in Manufacturing

Quality control ensures that the 24v led indicator lights meet the required standards, including:

- Brightness.

- Lifespan.

- Compliance with regulations.

Customization in Manufacturing

Customized 24v LED indicator lights, like 8mm mini IP67 277v indicator light, can be manufactured to meet specific requirements.

Environmental Considerations in Manufacturing

Considering the environmental impact in manufacturing includes:

- Reducing waste.

- Using eco-friendly materials.

- Energy-efficient manufacturing processes.

Labor and Skill Requirements

Skilled labor is essential for:

- Designing.

- Assembling.

- Quality control.

Global Trends in Manufacturing

Global trends like automation, sustainability, and customization are shaping the manufacturing of 24v led indicator lights.

Conclusion on 24v LED Indicator Light Manufacturing

The manufacturing of 24v led indicator lights involves intricate processes and considerations. Ensuring quality control, customization possibilities, and adherence to environmental standards is essential for producing a competitive product.

What are the practical considerations when using 120v led panel indicator lights?

Introduction to 120v LED Panel Indicator Lights

120v led panel indicator lights are widely used in North America for various signaling purposes. Practical considerations are essential for optimal performance and safety.

Placement and Mounting

Proper placement and mounting options, like those found in 8mm 120v panel mount indicator light, ensure visibility and aesthetic appeal.

Voltage Requirements

Understanding the voltage requirements is vital, as 120v led panel indicator lights are designed for specific voltage input.

Color Selection

Choosing the right color for the specific signaling purpose enhances functionality.

Compatibility with Existing Systems

Ensuring compatibility with existing panels or circuits is essential for smooth integration.

Energy Efficiency Considerations

120v led panel indicator lights are energy-efficient but selecting ones with additional energy-saving features can be beneficial.

Legal Compliance and Standards

Adherence to legal standards ensures safety and avoids legal issues.

Customization Possibilities

Options for customization in size, color, brightness are available, like 8mm 12v vending blue led indicator light.

Maintenance Considerations

Understanding the maintenance requirements ensures longevity and continued performance.

Environmental Impact

Considering eco-friendly 120v led panel indicator lights aligns with sustainability goals.

Technology Integration

Integration with modern technologies like smart controls adds versatility.

Market Trends

Staying abreast of market trends in LED technology ensures up-to-date applications.

Conclusion on Practical Considerations for 120v LED Panel Indicator Lights

Practical considerations for using 120v led panel indicator lights encompass placement, compatibility, customization, legal compliance, and more. Attention to these factors ensures optimal performance and safety.

How do 24v led indicator lights compare to other voltage indicator lights?

Introduction to 24v LED Indicator Lights Comparison

24v led indicator lights are commonly used in industrial and automotive applications. Comparing them to other voltage indicator lights like 12v or 120v helps in choosing the right option.

Comparison with 12v LED Indicator Lights

- Application: 24v is often used inindustrial settings, while 12v is common in consumer products.

- Energy Efficiency: Similar efficiency, but 24v might be more suitable for higher energy needs.

- Compatibility: 24v systems might require specific wiring or resistors.

- Customization: Similar customization options like 8mm 110v metal green led indicator light.

Comparison with 120v LED Indicator Lights

- Application: 120v is standard in North America for household and industrial uses, while 24v is more specific to certain applications.

- Energy Consumption: 24v is usually more energy-efficient.

- Safety Considerations: 24v is considered safer in terms of electrical shock risk.

- Environmental Impact: Both are eco-friendly but choosing the right voltage for the application minimizes energy waste.

Comparison with Other Voltages

Other voltages like 220v or 277v have specific applications and considerations. Understanding these helps in selecting the right voltage.

Customization Across Voltages

Customization in color, mounting, brightness is possible across different voltages, including 8mm yellow led indicator light 220v.

Global Trends

Global trends in energy efficiency and technological advancements affect all voltage levels of LED indicator lights.

Conclusion on 24v LED Indicator Lights Comparison

Comparing 24v led indicator lights with other voltages helps in understanding their unique features and considerations. The choice depends on factors like application, energy efficiency, safety, and customization possibilities.

What are the different types of waterproof LED indicator lights?

Introduction to Waterproof LED Indicator Lights

Waterproof LED indicator lights are specially designed to operate in wet or humid conditions. They are used in various applications, ranging from marine to outdoor signage.

Types of Waterproof LED Indicator Lights

- IP67 Rated LED Indicator Lights: Highly water-resistant, like 8mm mini IP67 277v indicator light.

- Marine LED Indicator Lights: Used in boats and marine applications.

- Outdoor LED Indicator Lights: For outdoor signage or garden lights.

- Industrial Waterproof LED Indicator Lights: For harsh industrial environments.

Features of Waterproof LED Indicator Lights

Features include:

- Water resistance according to IP ratings.

- Durability against environmental conditions.

- Energy efficiency.

Applications of Waterproof LED Indicator Lights

These lights are used in:

- Marine Environments: Boats, docks, etc.

- Outdoor Spaces: Gardens, pathways.

- Industries: Where exposure to water or humidity is common.

Customization Options

Customization in size, color, brightness, and more is available, like 8mm IP65 12 volt indicator light for bike.

Safety Considerations

Ensuring proper safety standards, like appropriate IP ratings, is essential for preventing electrical hazards in wet environments.

Environmental Considerations

Using environmentally friendly materials and energy-efficient designs aligns with sustainability goals.

Market Trends

The trend towards outdoor living and industrial automation is driving the demand for waterproof LED indicator lights.

Technological Innovations

Technological advancements enable more features like smart controls in waterproof LED indicator lights.

Conclusion on Waterproof LED Indicator Lights

Waterproof LED indicator lights offer versatile and safe solutions for wet and humid conditions. Understanding the different types, features, and applications allows for the optimal utilization of these specialized lights.

What materials are used in the manufacturing of LED indicator lights?

Introduction to Materials in LED Indicator Light Manufacturing

LED indicator lights are composed of various materials that affect their performance, appearance, and durability. Understanding these materials helps in choosing the right products like 8mm IP65 12 volt indicator light for bike.

LED Chip Material

The LED chip itself can be made from:

- Inorganic Materials: Such as gallium arsenide (GaAs) and gallium nitride (GaN).

- Organic Materials: Used in OLEDs.

Housing Materials

Housing materials include:

- Metals: Like aluminum, for heat dissipation.

- Plastics: Such as polycarbonate, for lightweight designs.

- Ceramics: For high-temperature resistance.

Lens Materials

Lens materials can be:

- Glass: For clarity and durability.

- Plastics: Like acrylic, for lightweight and flexibility.

Electrical Components

Wires, resistors, and other electrical components are made from materials like:

- Copper: For wiring.

- Silicon: In semiconductors.

- Various Alloys: For specific functions.

Environmental Considerations in Material Selection

Choosing eco-friendly materials and processes is vital for sustainability.

Customization Possibilities

Materials can be chosen to customize features like color, brightness, durability, such as in 8mm 12v vending blue led indicator light.

Material selection impacts:

- Brightness.

- Energy efficiency.

- Lifespan.

Global Trends in Material Selection

Global trends like sustainability and innovation are influencing material selection in LED indicator light manufacturing.

Conclusion on Materials in LED Indicator Light Manufacturing

The materials used in LED indicator lights manufacturing define their features and functionalities. Understanding these materials and their implications assists in making informed choices for specific applications.

What are the global trends in LED indicator lights?

Introduction to Global Trends in LED Indicator Lights

LED indicator lights are being influenced by various global trends that shape their design, functionality, and market dynamics. Recognizing these trends aids in understanding the evolving landscape.

Trend Towards Energy Efficiency

The drive towards energy efficiency is leading to:

- Improved LED technology.

- Adoption of energy-saving features.

Trend Towards Customization

Customization in size, color, brightness is becoming popular, like 8mm 110v metal green led indicator light.

Trend Towards Automation and Smart Controls

Integration with smart technologies is allowing:

- Remote control.

- Integration with IoT devices.

Trend Towards Sustainability

Focus on sustainability is driving:

- Eco-friendly materials.

- Energy-efficient designs.

Trend Towards Miniaturization

Smaller sizes like 8mm mini IP67 277v indicator light are becoming prevalent, allowing for more compact designs.

Trend Towards Globalization

Globalization is influencing:

- Market expansion.

- Cross-border collaborations.

Trend Towards Compliance with Regulations

Meeting global standards and regulations ensures: –

Quality assurance.

Market Trends in Different Regions

Different regions may have unique trends, like:

- Demand for specific voltages.

- Preference for certain colors or sizes.

Impact of Technological Innovations

Technological advancements are enabling:

- Improved features.

- Higher performance.

Conclusion on Global Trends in LED Indicator Lights

Understanding the global trends in LED indicator lights provides insights into the evolving market and technological landscape. These trends reflect the priorities and preferences of consumers, industries, and governments.

What factors should be considered when choosing LED indicator lights?

Introduction to Choosing LED Indicator Lights

Choosing the right LED indicator lights involves considering various factors that align with the intended application, requirements, and preferences. Options like 8mm 110v metal green led indicator light provide different choices.

Consideration of Voltage

Voltage selection depends on:

- Application needs.

- Compatibility with existing systems.

Consideration of Water Resistance

Water resistance might be essential for applications like:

- Marine environments.

- Outdoor signage.

Consideration of Material

Material choices affect:

Consideration of Size and Shape

Size and shape, like 8mm 12v vending blue led indicator light, influence:

- Mounting options.

- Aesthetic preferences.

Consideration of Brightness

Brightness levels must be suitable for:

- Visibility requirements.

- Energy consumption.

Consideration of Color

Color choices are important for:

- Aesthetic appeal.

- Functional indications (e.g., red for stop, green for go).

Consideration of Energy Efficiency

Energy-efficient options align with:

- Cost savings.

- Environmental goals.

Consideration of Customization Options

Customization possibilities enable:

- Specific features.

- Unique designs.

Consideration of Safety Standards

Adherence to safety standards ensures:

- Risk mitigation.

- Compliance with regulations.

Consideration of Environmental Impact

Environmental considerations involve:

- Eco-friendly materials.

- Energy-saving designs.

Conclusion on Choosing LED Indicator Lights

Considering various factors such as voltage, water resistance, material, size, brightness, color, energy efficiency, customization, safety standards, and environmental impact enables the right choice of LED indicator lights. Such comprehensive considerations help in aligning the lights with specific needs and preferences.

What are the application areas of LED indicator lights in the industrial sector?

Introduction to Industrial Applications of LED Indicator Lights

LED indicator lights play a vital role in the industrial sector, offering efficient and reliable signaling solutions. From manufacturing lines to safety systems, these lights are indispensable.

Application in Manufacturing Lines

LED indicator lights are used in manufacturing to:

- Signal operational status.

- Indicate errors or warnings.

Application in Safety Systems

Safety systems utilize these lights to:

- Provide visual alarms.

- Indicate emergency exits.

Application in Control Panels

Control panels often include LED indicator lights to:

- Show system status.

- Facilitate user interactions.

Application in Automation Systems

Automation systems rely on LED indicator lights for:

- Real-time feedback.

- Process control.

Application in Marine Industry

In marine industrial settings, waterproof LED lights like 8mm IP65 12 volt indicator light for bike are used for:

Application in Mining Industry

In the mining industry, LED indicator lights are crucial for:

- Safety signaling.

- Equipment status indication.

Application in Healthcare Industry

In the healthcare industry, LED lights are used for:

- Medical equipment status.

- Room occupancy indications.

Application in Transportation Industry

Transportation systems use LED indicator lights for:

- Traffic signals.

- Vehicle indicators.

Application in Energy Sector

In the energy sector, these lights signal:

- Power status.

- Fault indications.

Customized Industrial Applications

Customization in size, color, and brightness, like 8mm 12v vending blue led indicator light, enables specific industrial applications.

Conclusion on Industrial Applications of LED Indicator Lights

The industrial applications of LED indicator lights are diverse and essential. They serve various functions across sectors like manufacturing, safety, control, automation, marine, mining, healthcare, transportation, energy, and can be customized for particular needs. Understanding these applications helps in optimizing the usage of these vital components in industrial settings.

What are the advantages and disadvantages of LED indicator lights?

Introduction to Advantages and Disadvantages of LED Indicator Lights

LED indicator lights offer numerous advantages and some disadvantages. Understanding these helps in making informed decisions.

Conclusion on Advantages and Disadvantages of LED Indicator Lights

LED indicator lights present significant advantages like energy efficiency, long lifespan, versatility, environmental friendliness, safety, and customization. However, they also have certain disadvantages like higher initial cost, sensitivity to temperature, complexity in design, and potential color shift. Balancing these aspects allows for the effective utilization of LED indicator lights.