Warning Beacon Lights: A Comprehensive Guide

Warning Beacon Lights are vital safety instruments employed across a multitude of industries, from emergency response to construction and marine applications. This comprehensive guide delves into the varied types of Warning Beacon Lights, including LED beacon strobe lights, construction beacon lights, and magnetic beacon lights, exploring their functionalities, technological advancements, maintenance practices, common issues, and emerging trends. Whether you’re a professional seeking guidance on regulatory compliance or someone interested in the aesthetic and innovative aspects of these lights, this article offers a thorough insight into Warning Beacon Lights, aiding you in making informed decisions.

What Are the Different Types of Warning Beacon Lights and Their Uses?

LED Beacon Strobe Light

LED Beacon Strobe Lights are powerful signaling devices used for emergency purposes. They emit intense flashing lights and are commonly used by emergency vehicles, traffic control, and industrial applications. You can find quality LED indicator lights at this link.

Magnetic Beacon Light

Magnetic Beacon Lights attach securely to metal surfaces and are typically used for temporary applications, such as on construction vehicles or during roadside repairs. They are convenient and provide excellent visibility. More on LED indicators can be found here.

Rotating Beacon Light

Rotating Beacon Lights produce a rotating effect that is highly noticeable from a distance. Often used by emergency services, airports, and on construction sites, they provide an essential visual warning. For a variety of LED indicator lights, visit this link.

LED Beacon Light

LED Beacon Lights offer energy efficiency and long-lasting performance. They are widely used in various applications, including automotive, marine, and industrial sectors. Check out 12-volt LED indicator lights here.

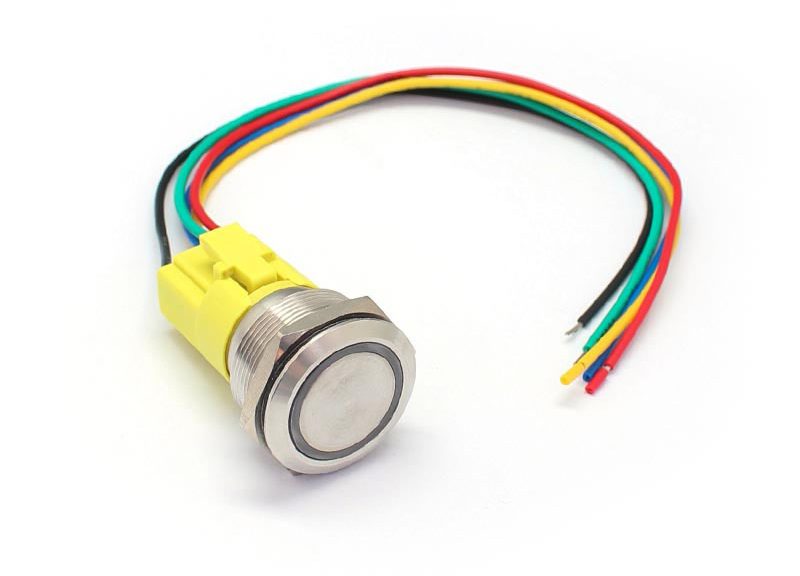

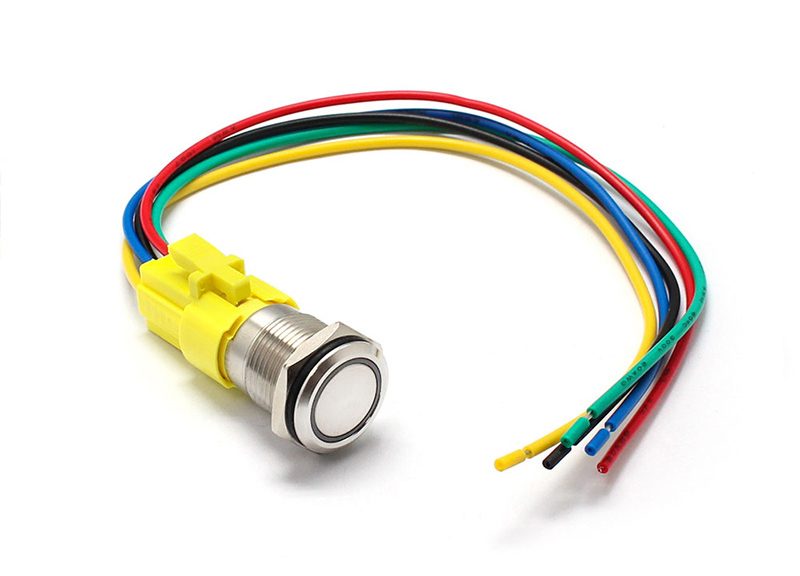

LED Beacon Lights for Trucks

Designed specifically for trucks, these beacon lights enhance safety and visibility, especially during nighttime operations or in poor weather conditions. More on LED FILN indicator light lamps with wire can be found here.

Construction Beacon Light

Construction Beacon Lights are vital for safety on construction sites. They help to warn people and vehicles of potential hazards and ongoing work. View double color metal pilot indicator lights here.

Beacon Light Bar

Beacon Light Bars are often used on emergency and utility vehicles. They provide a powerful visual alert and can include various light patterns. Explore the metal red-green two-tone common cathode here.

LED Beacon Light Bar

Combining the efficiency of LED technology with the functionality of light bars, LED Beacon Light Bars are used on emergency, police, and service vehicles. Check the common anode metal indicator light options here.

How Do Warning Beacon Lights Function in Various Industries?

In Emergency Services

Warning Beacon Lights in emergency services such as fire, police, and ambulance vehicles are crucial. They provide:

- Immediate Recognition: The distinct flashing helps in immediate identification of emergency vehicles.

- Safety: They ensure the safety of the personnel and the public by alerting nearby vehicles and pedestrians.

- Directional Assistance: Through different flash patterns, they guide other drivers to make way for emergency vehicles.

For a variety of double color LED metal indicator lights, visit this link.

In Construction

In the construction industry, Warning Beacon Lights play several roles:

- Visibility: They enhance visibility at construction sites, especially during nighttime or low-light conditions.

- Hazard Warning: They are used to mark hazards, ensuring safety for workers and the general public.

- Equipment Identification: They are used on heavy machinery to indicate they are in operation, adding an extra layer of safety.

Check out panel metal pilot indicator lights here.

In Marine Applications

Warning Beacon Lights are essential in marine applications:

- Navigation: They are used to guide ships, marking navigational routes, obstructions, and other vital information.

- Distress Signal: They can be used as a signal for help in emergency situations.

- Port Operations: They ensure safe and efficient operations within ports and harbors.

Find high voltage indicating lights here.

How to Choose the Right Warning Beacon Light for Your Needs?

Consider the Purpose

The purpose of the Warning Beacon Light must be clear. Whether it’s for emergency, construction, or marine use, the specific requirements will vary. Check out metal flameproof indicating lights here.

Check the Regulations

Compliance with local regulations and standards is essential. Different jurisdictions may have varying requirements for brightness, color, and flash patterns.

Assess the Durability

Durability is vital, especially for Warning Beacon Lights used outdoors or in harsh conditions. Consider factors like waterproofing and shock resistance. Visit this link for red LED pilot indicator lights.

Choose the Right Technology

Selecting the appropriate technology, such as LED, rotating, or strobe, will depend on your specific needs and preferences. LED technology is generally preferred for its energy efficiency and longevity. Explore metal signal indicator lights here.

Look for Special Features

Special features like remote control, various flash patterns, and synchronization with other lights can add functionality and convenience.

Think About Installation

Ease of installation is a consideration, especially for temporary applications. Magnetic Beacon Lights, for instance, offer quick and easy attachment.

What Are the Safety Guidelines to Follow When Using Warning Beacon Lights?

Follow Manufacturer’s Instructions

Always adhere to the manufacturer’s guidelines for installation, usage, and maintenance. For power box metal indicator lights, visit this link.

Comply with Local Laws

Understanding and complying with local laws and regulations regarding the use of Warning Beacon Lights is essential. This ensures legal operation and avoids potential fines or penalties.

Use Appropriate Colors

Different colors of Warning Beacon Lights may be reserved for specific purposes. For example, red is typically used for emergency vehicles, while amber is common for construction and utility vehicles.

Maintain Regularly

Regular maintenance and inspections are vital to ensure that the Warning Beacon Lights are in proper working condition. This includes checking for any damages, wear, and tear, and replacing bulbs or parts as needed. Find high-pressure indicator lights here.

Consider Environmental Conditions

Environmental conditions like fog, rain, or snow can affect the visibility of Warning Beacon Lights. Understanding these factors and choosing the right type of light accordingly is crucial.

Educate Users

If Warning Beacon Lights are being used in a professional setting, it’s essential to provide proper training and education to the users. This helps in correct usage and enhances safety.

Don’t Overuse

Overusing Warning Beacon Lights when not necessary can reduce their effectiveness and may lead to confusion or misunderstandings.

What are the Technological Advancements in Warning Beacon Lights?

Energy Efficiency

With the advancement in LED technology, modern Warning Beacon Lights are more energy-efficient. They consume less power while providing bright and effective illumination. Explore medical equipment indicator lights [here](

https://www.indicatorlight.com/medical-equipment-indicator-light/).

Improved Durability

New materials and design techniques have led to Warning Beacon Lights that are more robust and able to withstand harsh weather conditions. This is especially beneficial for outdoor and industrial applications.

Smart Controls

Smart controls enable users to customize the light patterns, intensity, and other features through remote control or even mobile apps.

Integration with Other Systems

Modern Warning Beacon Lights can be integrated with other security and safety systems, providing a cohesive approach to emergency response or hazard management.

Eco-Friendly Options

Some manufacturers are focusing on producing eco-friendly Warning Beacon Lights that minimize environmental impact through energy efficiency and sustainable materials. Check waterproof IP67 metal indicator lights here.

Increased Customization

Customization in terms of colors, flash patterns, and additional features allows users to have Warning Beacon Lights tailored to their specific needs and preferences.

Development of Miniaturized Versions

Compact and miniaturized versions of Warning Beacon Lights are now available, providing more versatile applications without sacrificing performance.

Enhanced Aesthetics

Modern designs are not only functional but aesthetically pleasing as well. This is particularly relevant for Warning Beacon Lights used in architectural or decorative applications.

How to Maintain Warning Beacon Lights for Longevity?

Regular Inspection

Inspecting Warning Beacon Lights for any signs of wear and tear, cracks, or damages is vital. Regular inspection helps in early detection of any problems.

Clean Properly

Dirt and debris can reduce the effectiveness of Warning Beacon Lights. Cleaning them with appropriate cleaning agents and according to the manufacturer’s instructions is essential. Visit this link for more options.

Replace Damaged Parts

Replacing any damaged or worn-out parts promptly ensures that the Warning Beacon Lights continue to function optimally.

Avoid Misuse

Misuse or improper handling can lead to damages. Following the correct usage guidelines prolongs the lifespan of Warning Beacon Lights.

Consider Environmental Factors

Taking into consideration environmental factors like temperature, humidity, and exposure to chemicals ensures that the Warning Beacon Lights are used in suitable conditions, enhancing their longevity.

Store Properly

If the Warning Beacon Lights are not in use, storing them properly in a cool, dry place helps in maintaining their condition.

Use Compatible Accessories

Using compatible accessories, such as mounts or power supplies, ensures that the Warning Beacon Lights function without any issues.

Consult Professionals if Needed

If you encounter any problems with the Warning Beacon Lights, consulting professionals or authorized service centers ensures that the issue is addressed appropriately.

What Are the Leading Brands and Manufacturers of Warning Beacon Lights?

Brand A

Specializing in LED technology, Brand A offers a wide range of LED beacon strobe lights, LED beacon light bars, and other related products.

Brand B

Brand B focuses on innovative solutions, providing customizable and smart-controlled Warning Beacon Lights for various applications.

Brand C

Known for its robust construction beacon lights, Brand C caters mainly to the industrial and construction sectors.

Brand D

With a diverse product line, Brand D offers Warning Beacon Lights for marine, automotive, and emergency services, emphasizing quality and performance.

Brand E

Brand E offers eco-friendly Warning Beacon Lights, focusing on sustainability and environmental consciousness.

Brand F

Brand F provides specialized Warning Beacon Lights for trucks, featuring easy installation and durable designs.

Brand G

Brand G is a leading provider of magnetic beacon lights, providing versatile and convenient solutions for temporary applications.

Brand H

Focusing on aesthetics and design, Brand H offers Warning Beacon Lights that are not only functional but visually appealing as well.

What Regulations Govern the Use of Warning Beacon Lights?

Understanding Compliance and Standards

Compliance with various national and international standards and regulations ensures that the Warning Beacon Lights meet the necessary safety and performance requirements.

Federal Regulations

In many countries, federal regulations define the requirements for Warning Beacon Lights, particularly in vehicles such as emergency services or construction.

Industry-Specific Standards

Different industries might have specific standards governing the use of Warning Beacon Lights, including maritime, aviation, or manufacturing sectors.

Local Laws and Ordinances

Local laws might also influence the use and installation of Warning Beacon Lights, depending on the region or municipality.

Environmental Considerations

Some regulations might emphasize eco-friendly practices, ensuring that Warning Beacon Lights meet certain sustainability or energy-efficiency criteria.

Certification Bodies

Various certification bodies or agencies might oversee the testing and certification of Warning Beacon Lights, ensuring that they adhere to all applicable standards and regulations.

Import and Export Laws

International trade laws might influence the import and export of Warning Beacon Lights, particularly if they have to meet specific international standards.

How to Choose the Right Warning Beacon Lights for Different Applications?

Identify the Purpose

Understanding the specific purpose or application helps in selecting the right type of Warning Beacon Lights, be it for emergency services, construction, marine, or other uses.

Consider the Installation

The installation method and location play a crucial role in selecting the Warning Beacon Lights, whether it’s permanent mounting, magnetic mounting, or temporary placement.

Look for Compliance and Certification

Ensuring that the Warning Beacon Lights meet the required compliance and certification guarantees their reliability and adherence to regulations.

Assess the Power Source

Consideration of the available power source, whether it’s a vehicle’s electrical system, batteries, or solar, affects the choice of Warning Beacon Lights.

Evaluate Durability and Weather Resistance

For outdoor or rugged applications, durability and weather resistance are key factors in choosing Warning Beacon Lights.

Analyze Functionality and Features

The functionality and additional features such as remote control, customization, or integration with other systems can influence the choice of Warning Beacon Lights.

Consult Experts if Necessary

Consulting experts or manufacturers can provide valuable insights into the most suitable Warning Beacon Lights for specific applications.

What Are the Common Problems with Warning Beacon Lights, and How to Troubleshoot Them?

Faulty Wiring

Faulty wiring can cause Warning Beacon Lights to malfunction. Regular inspection and proper connection can resolve this issue.

Burned-Out Bulb

If a bulb burns out in the Warning Beacon Lights, replacing it with a suitable replacement following the manufacturer’s instructions is essential.

Damaged Housing or Lens

Damage to the housing or lens might reduce the effectiveness of Warning Beacon Lights. Repair or replacement might be required.

Malfunctioning Control Systems

If the control systems of the Warning Beacon Lights malfunction, troubleshooting according to the user manual or consulting a professional might be necessary.

Incompatibility with Power Source

Ensuring compatibility with the power source and using appropriate accessories can prevent problems related to power in Warning Beacon Lights.

Environmental Damage

Exposure to harsh environmental conditions might lead to problems in Warning Beacon Lights. Choosing suitable models for the specific environment and regular maintenance can mitigate this issue.

Future Trends in Warning Beacon Lights

Integration with IoT

Internet of Things (IoT) integration will enable more intelligent control and monitoring of Warning Beacon Lights, enhancing their functionality.

Use of Renewable Energy

Future Warning Beacon Lights may increasingly utilize renewable energy sources like solar power, aligning with global sustainability goals.

Development of Adaptive Systems

Adaptive Warning Beacon Lights that can change patterns or intensity based on the situation or environment are expected to be developed.

Enhancement in Energy Efficiency

Energy-efficient Warning Beacon Lights will become more prevalent, reducing energy consumption without compromising performance.

Focus on Miniaturization and Versatility

Further miniaturization and versatility in design will provide more flexible applications for Warning Beacon Lights.

Emphasis on Aesthetic Design

The future trend may include an emphasis on aesthetic design, making Warning Beacon Lights suitable for various decorative or architectural purposes.

Conclusion

Warning Beacon Lights are essential safety devices used across various industries, including emergency services, construction, marine, and more. Understanding the types, functions, technological advancements, maintenance practices, and leading brands is vital in selecting the right Warning Beacon Lights for your needs. From LED beacon strobe lights to construction beacon lights and everything in between, this comprehensive guide provides insights into the world of Warning Beacon Lights. Whether you are looking for products for industrial use, personal vehicles, or special applications, knowing your requirements, compliance with regulations, and focusing on quality will ensure that you choose the right product.