In this extensive guide, we delve into everything you need to know about push button metal, from their versatility in various applications like industrial control panels, emergency systems, and even clothing, to considerations for their installation, safety, and maintenance. Whether you’re contemplating a purchase, looking to customize, or interested in understanding their various types like illuminated and waterproof options, this article offers a 360-degree view to help you make well-informed decisions. Intrigued? Read on to get a thorough understanding of metal push buttons.

Metal push buttons come in various forms designed for different applications. There are several types of metal push buttons available in the market, categorized based on factors like material, illumination, and use-case scenarios.

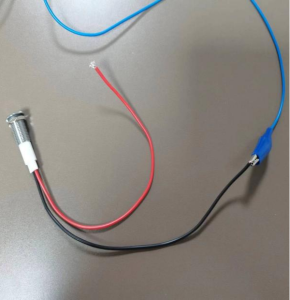

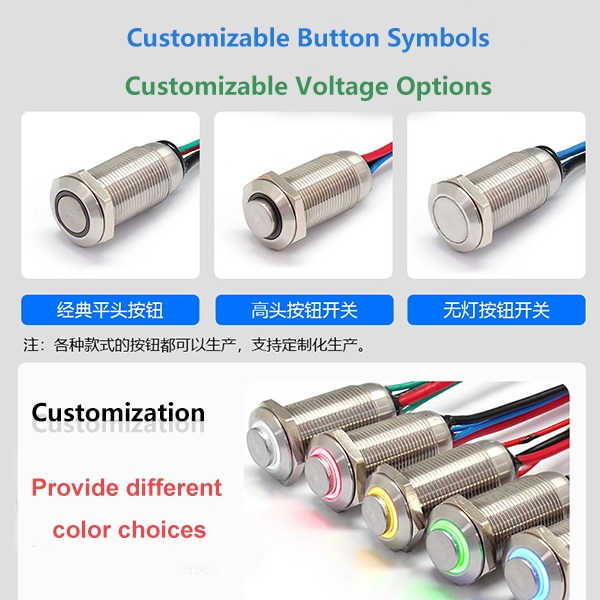

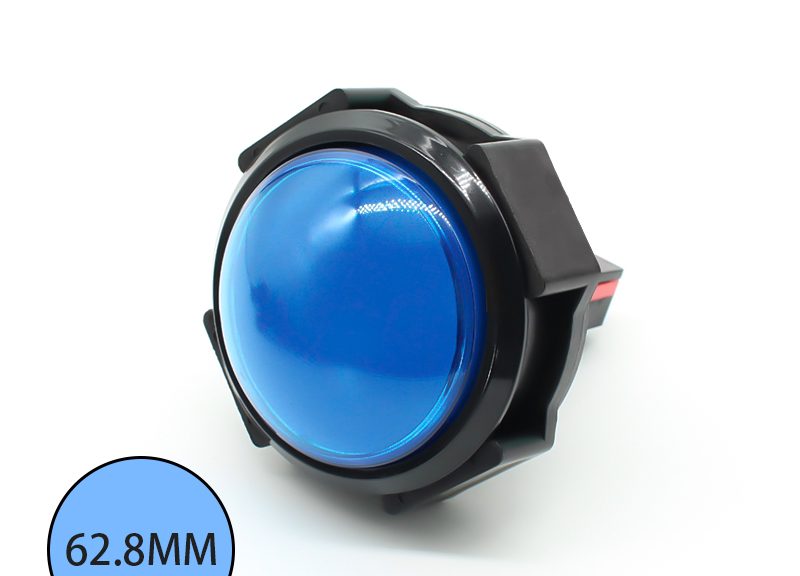

Non-Illuminated Vs. Illuminated Metal Push Buttons:Non-illuminated push buttons are generally simpler and have a basic design. In contrast, illuminated push buttons contain a light, usually LED, to indicate the button’s status or to assist in low-light conditions. The illuminated push button options offer enhanced visibility, especially in dark or dim environments.

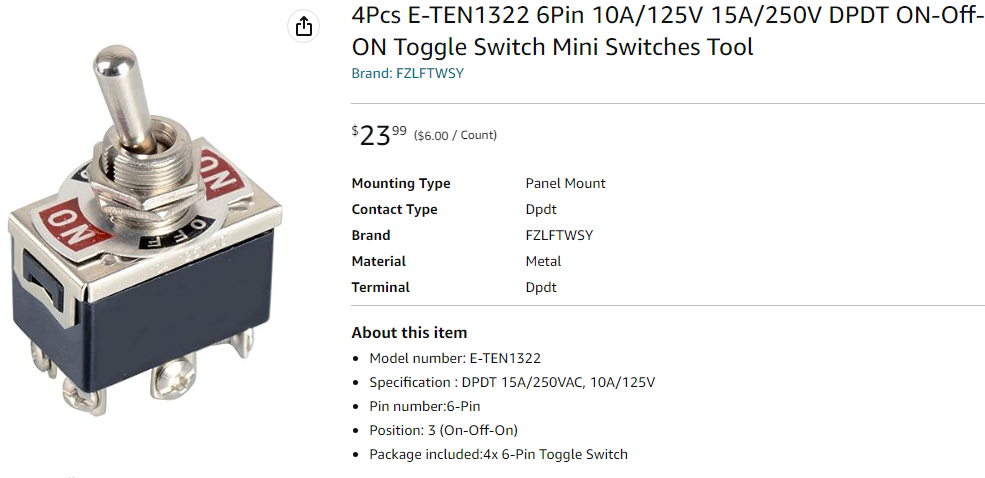

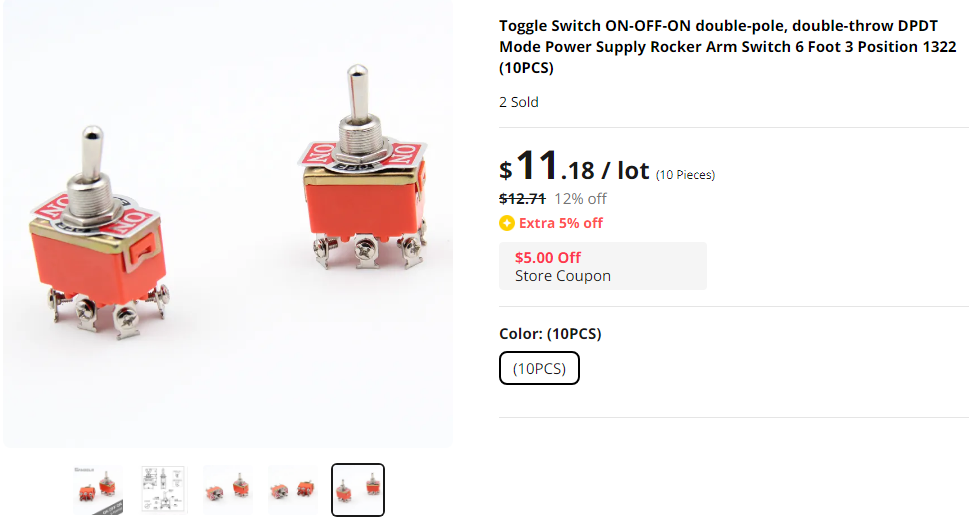

Metal Push Button Switch Vs. Metal Momentary Push Button:A metal push button switch is typically a latching type, which means it maintains its state until pressed again. On the other hand, a metal momentary push button returns to its initial position as soon as you release the button.

Flat Head Vs. Round Head Push Buttons:Flat head metal push buttons provide a sleek, modern appearance but may not be as ergonomically satisfying to use. You can read more about them here. Round head push buttons offer a more traditional look and are generally considered more comfortable to press.

The durability and longevity of a metal push button often depend on the materials used in its construction. Different applications call for various types of materials, which serve specific purposes.

Stainless Steel Push Buttons:Stainless steel push buttons are renowned for their durability and corrosion resistance, making them ideal for outdoor applications and harsh environments.

Aluminum Push Buttons:Aluminum push buttons are lighter and more affordable than their stainless steel counterparts, but they are less resistant to corrosion.

Brass Push Buttons:Brass buttons provide a luxurious feel and look, often used in more aesthetic applications like high-end electronics or furniture.

The functioning of metal push buttons may seem straightforward but involves some mechanical and electrical principles. Understanding these basics can help you make an informed choice when selecting a push button for your project or application.

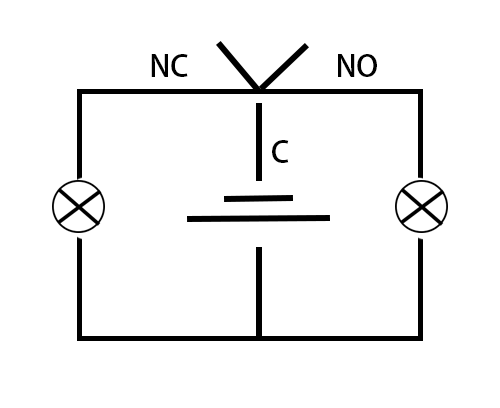

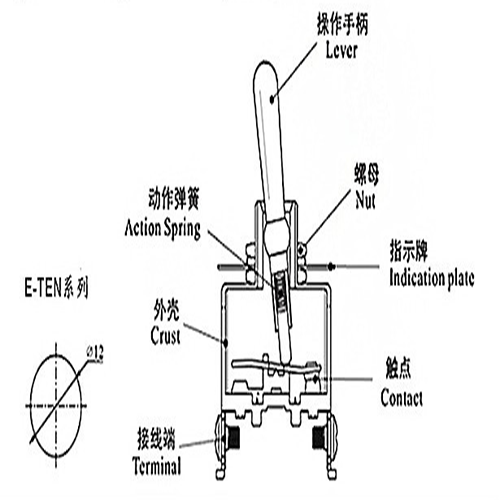

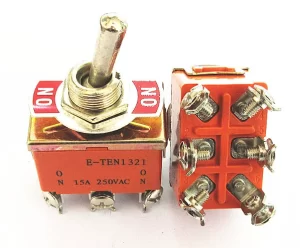

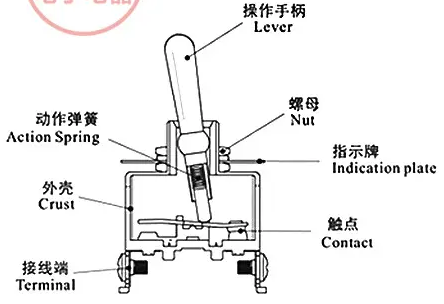

Mechanical Operation:Mechanically, a metal push button works by pressing down a plunger that activates a set of internal contacts. This action either opens or closes an electrical circuit.

Electrical Operation:Electrically, when the button is pushed, it either opens or closes an electrical circuit, allowing the current to flow through it. This mechanism is usually achieved through the internal contacts mentioned earlier.

Types of Electrical Operation”Metal push buttons can operate as either momentary or latching switches. A momentary button will return to its initial state when released, while a latching button will remain in its pressed state until pressed again.

The environment where a push button metal is to be installed often determines whether it should be water and dust resistant.

IP Rating:Many push buttons come with an IP (Ingress Protection) rating that specifies their resistance to dust and water. For example, a waterproof metal push button with an IP67 rating is dust-tight and can withstand temporary submersion in water.

Materials:The materials used in the construction of the button also play a role in its water and dust resistance. For instance, stainless steel buttons are more resistant to such factors compared to aluminum buttons.

Seals and Gaskets:Some metal push buttons come with added seals or gaskets to improve their resistance to environmental factors. These are often found in industrial-grade buttons intended for harsh environments.

Metal push buttons are ubiquitous, and their applications can range from simple household uses to complex industrial setups.

Industrial Applications:Metal push buttons are commonly used in machinery, control panels, and other industrial settings. They are particularly popular in environments where durability and reliability are paramount.

Consumer Electronics:Many consumer electronics like coffee machines, ovens, and even elevators make use of metal push buttons for their aesthetic appeal and durability.

Automotive Industry:In automobiles, metal push buttons are often used for starter systems, horn systems, and other control mechanisms within the car.

Choosing the right metal push button involves various factors including the intended use, installation environment, and specific features needed.

Intended Use”It’s essential to consider the primary function that the button will serve. For instance, if it’s for a critical operation, you might want to opt for a highly durable, latch metal push button switch with LED.

Installation Environment:Where the button will be installed can significantly impact its longevity. If the button is to be used outdoors or in a harsh environment, opt for a more durable and water-resistant option.

Additional Features:Features like illumination, switch type (momentary or latching), and button shape can also influence your decision.

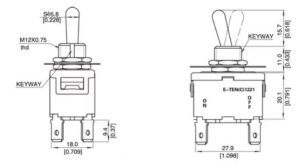

Installation can vary significantly based on the type of metal push button and its intended application. However, some general guidelines can help you through the process.

Tools Required:Typically, you’ll need some basic tools like a screwdriver, pliers, and a wire stripper. Ensure you have these handy before beginning the installation.

Electrical Connections:Identify the electrical connections where the push button will be installed. Turn off any electrical power to this circuit to ensure safety during installation.

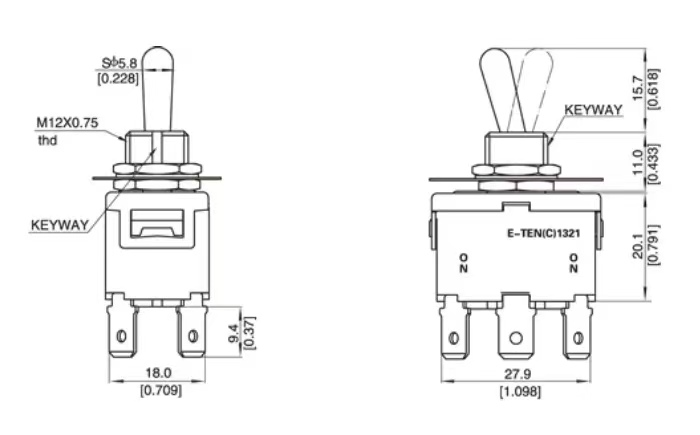

Mounting the Button:Many metal push buttons come with a threaded barrel and a nut for easy mounting. Simply insert the button through the pre-drilled hole in the panel and tighten the nut to secure it in place.

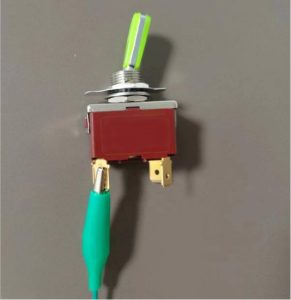

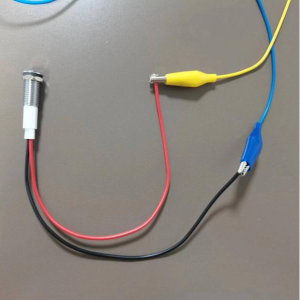

Wiring:The actual wiring can differ based on whether the button is a simple non-illuminated type or an illuminated push button with light. Follow the manufacturer’s guidelines to ensure correct wiring.

Testing:After all the connections are made, turn the power back on and test the button to ensure it’s working as intended.

Safety is a crucial aspect when using metal push buttons, especially in industrial settings. Here are some considerations:

Voltage and Current Ratings:Always pay attention to the voltage and current ratings of a push button to ensure it meets the requirements of your application.

Insulation and Grounding:Ensure that the button is properly insulated and grounded to prevent any electrical mishaps. This is especially important in industrial settings where the risk of electrical accidents is higher.

Regulatory Compliance:Depending on your jurisdiction, there may be safety standards and codes that your push button must meet. Always verify that the product you select is compliant with these regulations.

Customization is often a requirement for specific applications, and many manufacturers offer this service.

Custom Engravings:Some providers allow for the engraving of symbols, letters, or numbers on the button surface for easier identification.

Color Options:In addition to the standard metallic finishes, some push buttons can be customized to feature different colors, particularly for the illuminated types.

Special Features:Some manufacturers also offer special features like adjustable illumination levels, neopixel push buttons, or adafruit rugged metal pushbuttons for those who require more advanced options.

Like any other mechanical or electrical component, metal push buttons can wear out over time and may need replacement.

Visual Inspection:Signs of physical damage, such as cracks or deformities, are obvious indicators that a button needs replacement.

Functionality Test:If the button is not responding as it should or is functioning intermittently, it’s a clear sign that it needs to be replaced.

Lifespan:Check the manufacturer’s guidelines on the expected lifespan of the product. If your button has outlasted this period, it’s wise to consider a replacement.

Buying a metal push button may seem straightforward, but there are multiple channels through which they can be purchased.

Online Stores:One of the easiest methods is to order them online from specialized suppliers like Indicator Light. They offer a broad range of options, from simple push button electrical switches to more complex waterproof metal push button stop switches.

Physical Retailers:Electronics and hardware stores often carry a range of push buttons, although their selection might not be as extensive as online stores.

Directly from Manufacturers:For bulk orders or custom requirements, it might be more efficient to order directly from manufacturers.

To wrap up, push button metal is a versatile and essential component used in various applications. Its many types, materials, functionalities, and customization options make it a critical element in both consumer and industrial products. By considering your specific needs and environment, you can select the most suitable metal push button for your application.

While most people think of metal push buttons as an electrical component, they also have applications in fashion, specifically in clothing.

Utility and Aesthetic:In clothing, metal push buttons often serve both a functional and aesthetic role. They can be used as fasteners in jeans, jackets, and other types of apparel, offering a more robust and durable option than plastic buttons.

Materials Used:The buttons used in clothing are usually made from stainless steel push button materials or other types of corrosion-resistant metals. This ensures that they can withstand the rigors of frequent use and washing.

Customization:Much like their electrical counterparts, these buttons can be customized in various shapes, sizes, and finishes to match the garment’s design.

There are several types of metal push buttons available in the market, each with its unique features and applications.

Momentary Push Buttons:Metal momentary push buttons are designed to make a contact only when the button is pressed and return to their initial position once released.

Latching Push Buttons:Latching buttons maintain their state after being activated. Latch metal push button switches with LED are a popular variation, often used in industrial controls.

Illuminated Push Buttons:Illuminated push buttons come with an integrated LED light, making them ideal for applications where visibility is crucial.

Rotary Switches:Rotary switches are not strictly push buttons but are often used in similar applications. They allow for multiple settings controlled by rotating a knob.

How to Maintain Metal Push Buttons?

Maintaining metal push buttons is crucial for extending their lifespan and ensuring optimal functionality.

Regular Cleaning:Dirt and grime can affect the performance of push buttons. Regular cleaning with a soft cloth can help in maintaining their appearance and functionality.

Electrical Check-Up:For electrical buttons, periodic checks should be done to ensure that they are functioning correctly and safely. This includes checking for any loose wires or signs of corrosion.

Replacement Parts:Some push buttons come with replaceable parts, like springs or caps, which can be replaced individually, thereby extending the life of the entire unit.

Yes, metal push buttons can be used outdoors, but there are some key factors to consider.

Weather Resistance:Many metal push buttons are designed to be weather-resistant. Waterproof metal push button switches are specially designed for outdoor use and can withstand elements like rain and snow.

Material Consideration:Stainless steel or other corrosion-resistant materials are often recommended for outdoor use to withstand various weather conditions.

Electrical Safety:Extra care should be taken to ensure that all electrical connections are well-insulated and grounded, especially when installing metal 12V buzzers or other similar components outdoors.

The functioning of a metal push button largely depends on its type and application, but here are some general principles.

Simple Circuit Completion:In the most basic form, a push button works by completing an electrical circuit when pressed, allowing the current to flow through it.

Additional Features:Some push buttons come with additional features like illumination, red push button light, or even programmable functions, further complicating their operation.

Mechanical Aspects:The mechanical aspect involves a spring-loaded mechanism that returns the button to its original position after being pressed, in the case of momentary buttons.

Push button metal is a versatile component found in various applications, from electrical circuits to clothing. With different types, materials, and customizability options, it is essential to understand your specific requirements and environmental conditions to choose the right metal push button.

Absolutely, there are specialized metal push buttons designed to accommodate people with disabilities.

ADA Compliant Buttons:ADA compliant buttons are designed to meet the standards set by the Americans with Disabilities Act. These buttons are often larger and easier to press, facilitating use by people with mobility challenges.

Audio and Visual Indicators:Some specialized buttons come with audio or visual indicators like a neopixel push button or other illuminated options. These are useful for those with hearing or sight limitations.

Easy-to-Read Labels:Labels on these specialized buttons are often larger and clearer to read, sometimes with braille included, making them more accessible for people with visual impairments.

Innovation in the field of metal push buttons is continuous, and several trends are emerging.

Smart Push Buttons:Smart push buttons can be integrated into IoT (Internet of Things) systems, allowing them to be controlled remotely or through smart home systems.

Energy-Efficient Designs:With growing concerns about energy consumption, new designs are focusing on lower power requirements, particularly in the case of illuminated buttons.

Multi-Functional Buttons:The rise of multifunctional buttons that can perform more than one action is another trend. This is particularly relevant in industrial settings, where control panels are becoming increasingly compact.

Troubleshooting is essential for identifying and resolving issues that might occur with metal push buttons.

Check the Wiring:Loose or disconnected wires are often the culprits behind a malfunctioning button. Ensure that all connections are secure.

Examine for Physical Damage:Look for any signs of physical damage like cracks or dents, which may impair the button’s functionality.

Test with a Multimeter:Using a multimeter, you can check for electrical continuity when the button is pressed. If the multimeter doesn’t register any activity, it’s likely that the button is faulty and needs to be replaced.

In summary, metal push buttons are versatile components with wide-ranging applications, from industrial machinery to personal clothing. Whether you are installing a new system or maintaining an existing one, understanding the types, functionalities, and customizability options can help you select the most suitable metal push button for your needs.

When it comes to the cost-effectiveness of metal push buttons, several factors come into play.

Durability:Metal push buttons, particularly those made from stainless steel, are highly durable and can last for many years, offering good value for the money spent.

Application-Specific Needs:If your application demands a rugged or waterproof button, then metal buttons are more cost-effective in the long run compared to plastic buttons that might need frequent replacements.

Customization Costs:Customized metal buttons, such as those with illuminated push button features, can be more expensive upfront but offer specific functionalities that might be crucial for your application.

The installation process for metal push buttons depends on the specific type and application.

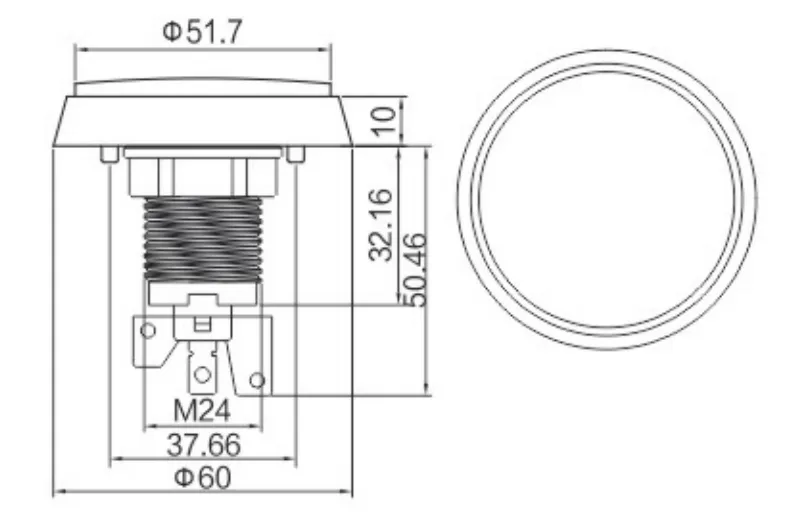

Preparing the Panel:The first step in installing a metal push button is preparing the control panel or surface where the button will be mounted. This might involve drilling holes to the size specified in the button’s datasheet.

Electrical Connections:Once the button is mounted, the next step involves making electrical connections. Here, it’s crucial to follow the wiring diagram provided by the manufacturer.

Final Checks:Before wrapping up the installation, a series of tests should be performed to ensure the button is functioning as expected. This could involve a simple press test or more complex electrical measurements.

Choosing the right metal push button can be a complex task, given the myriad options available.

Identify the Application:The first step is to identify the application where the button will be used. Is it for an industrial setting, for home use, or for clothing?

Material Considerations:Different materials offer different levels of durability and resistance. For instance, stainless steel push buttons are more durable and ideal for challenging environments.

Additional Features:Depending on your needs, you might want additional features like illumination, which can be found in push button with light models, or ruggedness, as offered by adafruit rugged metal pushbuttons.

By considering these factors, you can select the most appropriate metal push button for your specific needs.

When dealing with metal push buttons, safety should be a top priority, and several aspects deserve attention.

Electrical Safety:For push buttons used in electrical systems, ensure that they are appropriately rated for the current and voltage they will handle. Failing to do so can lead to malfunctions or, in the worst case, electrical fires.

Waterproofing:In environments where water or moisture is a concern, waterproof metal push buttons should be considered to prevent short circuits and subsequent electrical hazards.

Labels and Signage:Clear labeling is crucial, especially in industrial settings, to prevent incorrect operation that could lead to accidents. Symbols, text, and sometimes colors are used to indicate the button’s function clearly.

Yes, customization is a significant feature of metal push buttons.

Custom Engravings:Many suppliers offer the option to have custom engravings or labels on the button surface. This can be useful for unique applications or branding purposes.

Color Choices:With advancements in technology, you can now opt for metal push buttons in a variety of colors, including red push button light options for better visibility.

Size and Shape:From small buttons for clothing to large industrial buttons, there are options for custom sizes and shapes, including flat head metal push buttons.

Metal push buttons have found applications in the clothing industry as well.

Easy Fastening:In clothing, these buttons serve as an alternative to traditional buttons, providing an easy and quick method for fastening.

Aesthetic Appeal:Beyond their practical utility, metal push buttons in clothing also offer an aesthetic appeal. These buttons can come in various designs and finishes, adding a unique touch to garments.

Durability:Metal buttons tend to be more durable than their plastic counterparts, making them a popular choice for heavy-duty clothing items like jackets and workwear.

What Is the Maintenance Routine for Metal Push Buttons?

Maintenance is essential for ensuring the longevity and proper functioning of metal push buttons.

Regular Cleaning:Dust and debris can accumulate around the button, affecting its performance. Regular cleaning is advised to keep it in optimal condition.

Electrical Testing:In electrical applications, periodic testing should be conducted to ensure the button’s proper functionality. This might include resistance testing or continuity checks.

Replacement:Despite their durability, metal push buttons are not indestructible. If a button starts showing signs of wear and tear or malfunction, it may be time to consider a metal momentary push button as a replacement.

By keeping these maintenance tips in mind, you can ensure a long lifespan for your metal push buttons in various applications.

Industrial settings present unique challenges and requirements, and metal push buttons are often up to the task.

Control Panels:Metal push buttons are commonly used in control panels to operate machinery. These buttons can handle the tough conditions found in industrial environments, like extreme temperatures or exposure to corrosive substances.

Emergency Systems:In industrial settings, quick response in emergencies is crucial. Metal push buttons are often used in emergency stop systems, thanks to their durability and reliability.

Automated Systems:As automation becomes increasingly prevalent in industries, metal push buttons are often integrated into these systems to serve various functions, including initiating or halting automated sequences.

Purchasing metal push buttons online has its own set of considerations.

Reputable Seller:It’s vital to buy from a reputable seller to ensure you’re getting a quality product. Customer reviews and ratings can provide valuable insights.

Detailed Specifications:Online listings should include detailed specifications like dimensions, material, electrical ratings, and other features. This will help you to match the button to your specific needs.

Return Policy:Always check the return policy when buying online. If the product doesn’t meet your expectations or arrives damaged, you should be able to return it without hassle.

By considering these points, you can make a well-informed decision when purchasing metal push buttons online.

Conclusion:In this comprehensive guide, we’ve covered various aspects of metal push buttons, ranging from their types and applications to installation and maintenance tips. Whether you need a button for your industrial setup, your next fashion project, or any other application, understanding these facets can help you make an informed decision. Keep in mind the specific features that your situation demands, and don’t forget to adhere to safety guidelines when installing and using these versatile components.

.

.