Big push buttons are an essential component in various industries, gaming consoles, emergency systems, and even artistic installations. This comprehensive guide explores everything you need to know about big push buttons, including their types, applications, installation methods, customization options, safety considerations, troubleshooting, evolution, and creative uses in DIY projects. Whether you’re an industry professional, a gaming enthusiast, or a curious hobbyist, this article will provide you with valuable insights and ideas to leverage these fascinating devices. Dive in to discover the endless possibilities and innovations that big push buttons offer, and find out how they’ve become more than just switches in the world of technology and design.

Big push buttons are large, prominent switches used to control machinery, emergency systems, arcade games, and various other applications. These buttons come in different sizes and configurations and can be found in both industrial and commercial settings.

Understanding the Design and Functionality

Big push buttons are designed for easy access and visibility, often used in emergency situations. They are robust, reliable, and can be customized to fit specific needs. The 40mm push button switch is a common example found in various systems.

Usage in Industrial Environments

In industrial settings, big push buttons, including emergency stop buttons, are used to control machinery and equipment. They provide a convenient and quick way to shut down a system in case of an emergency. Check out this link for more on emergency stop buttons.

Application in Arcade Games

Big push buttons are also popular in arcade games, where they provide tactile feedback and a fun experience for the players. They come in various colors and shapes, like the massive arcade button and round arcade button.

There are several types of big push buttons available in the market, each serving different purposes.

Big dome push button Arduino is a large button often used in DIY projects and electronic applications. It can be integrated with Arduino boards to create interactive devices. The big push button switch is one example of this type.

Sparkfun’s big dome push buttons are widely used in educational projects and hobbyist creations. They are known for their quality and ease of use, suitable for both beginners and experts.

Large arcade buttons are used in gaming machines and provide a nostalgic feel. They are available in different sizes, such as the 60mm arcade button, and can be customized to fit any arcade machine.

The momentary push button switch is a type of button that only activates while being pressed. It’s commonly used in various applications, including automotive and industrial control systems. Check out momentary waterproof 12v round switches for more details.

Choosing the right big push button depends on various factors, including the application, design preferences, and budget.

Considering the Application

Understanding the specific application where the button will be used is crucial. For example, if you need a button for an emergency system, you might want to consider the emergency stop buttons.

Evaluating the Design

The design of the button, including its size, shape, and color, should align with the overall aesthetics of the system. For example, if you’re building an arcade machine, you might prefer colorful game machine buttons.

Assessing the Budget

Budget plays a vital role in choosing the right big push button. While there are premium options available, affordable yet quality buttons can also be found, such as 28mm push button switches.

Installation of big push buttons may vary depending on the type and application. However, some general guidelines can be followed.

Preparing the Surface

Before installing the button, ensure that the surface is clean and suitable for mounting. You may need specific tools and accessories depending on the type of button, such as custom automotive push button switches.

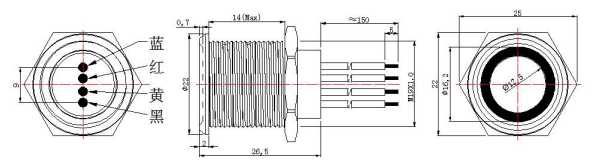

Connecting the Wires

Properly connecting the wires to the button ensures that it functions correctly. Depending on the type of button, such as the 25mm push button switch, the wiring can be simple or complex.

After installation, testing the button is essential to ensure its functionality. This might include pressing the button multiple times or using testing equipment for more complex systems.

How to Maintain Big Push Buttons?

Maintaining big push buttons is essential for their longevity and proper functioning. Here are some guidelines.

Regular Cleaning

Keeping the buttons clean is vital, especially in industrial settings. Regular cleaning with appropriate solutions ensures that the buttons remain responsive and free from dust and grime.

Periodic Inspection

A periodic inspection of the buttons helps in detecting any wear or damage early on. This is particularly important for buttons used in safety-critical applications, such as emergency stop buttons.

Replacement of Worn Parts

If any parts of the button are worn or damaged, timely replacement is crucial. Sourcing genuine parts from trusted suppliers, like Indicator Light’s button arcade collection, is recommended.

When looking to purchase big push buttons, considering popular brands and reliable sources is essential.

Popular Brands

Some well-known brands in the big push button industry include FILN, which offers products like FILN LED arcade buttons, and others that specialize in various types and designs.

Where to Buy

Big push buttons can be purchased from specialized suppliers, online marketplaces, and local stores. Websites like Indicator Light offer a wide range of options, including triangle arcade buttons and arcade button switches.

Big push buttons are not limited to industrial and commercial applications. They can be used creatively in various projects.

Art Installations

Artists often use big push buttons in interactive art installations, allowing viewers to engage with the artwork.

DIY Projects

For DIY enthusiasts, big push buttons offer endless possibilities. From home automation to creating fun toys for kids, the potential applications are vast.

Themed Events

Big push buttons can be used in themed events, such as game shows or parties. They add a fun and interactive element, enhancing the overall experience.

In conclusion, big push buttons are versatile and widely used

components in various fields. Understanding their types, applications, installation, and maintenance can help in making informed decisions. Whether it’s a huge red button for a specific project or a big red button clicker for gaming, the options are endless. Their unique and creative uses further add to their appeal, making them an essential part of modern technology and design.

Customizing big push buttons allows them to fit into specific applications and designs, enhancing functionality and aesthetics.

Selecting the Right Size

Choosing the right size for your big push button is crucial. Options range from 30mm push button switches to larger ones, depending on the requirement.

Choosing the Color

Colors add visual appeal and can be used to signify different functions. For example, red might be used for emergency stop buttons, while green could indicate a start button.

Adding Labels and Symbols

Labels and symbols provide clear instructions for the users. They can be customized to match the specific function of the button, such as emergency stop, play, or pause.

Incorporating LED Lights

Some big push buttons, like FILN LED arcade buttons, come with integrated LED lights. These lights add visual appeal and can also serve as indicators for the button’s status.

Safety is paramount when dealing with big push buttons, especially in industrial applications.

Compliance with Standards

Ensure that the big push buttons comply with relevant safety standards and regulations. This includes certifications, quality assurance, and proper labeling.

Proper Installation

Improper installation of big push buttons can lead to malfunction or accidents. Following the manufacturer’s instructions and consulting professionals if needed is essential.

Regular Maintenance and Inspection

Regular maintenance and inspection help in identifying any potential issues early on. This includes checking for wear and tear, electrical issues, and other potential hazards.

Integrating big push buttons with modern technology expands their functionality and allows for more sophisticated control.

Connection with Microcontrollers

Big push buttons can be connected to microcontrollers like Arduino for automation and control. This enables the creation of interactive devices and systems.

Integration with Software

Software integration allows big push buttons to interact with computer programs. This could be used in applications like custom control panels, gaming interfaces, or interactive displays.

Utilizing Wireless Technology

Incorporating wireless technology enables remote control and monitoring of big push buttons. This adds convenience and flexibility in various applications.

Big push buttons offer distinct advantages and characteristics compared to other types of buttons.

Visibility and Accessibility

Big push buttons are designed for easy visibility and accessibility. Their large size makes them suitable for applications where quick and clear access is required.

Durability

Due to their robust construction, big push buttons are often more durable than smaller buttons. They can withstand harsh environments, making them suitable for industrial use.

Versatility

The versatility of big push buttons is one of their key strengths. They can be customized and used in various applications, from industrial control systems to creative art installations.

Cost

While big push buttons might be more expensive than standard buttons, their unique features and customization options often justify the cost. Affordable options are also available, catering to different budget needs.

Environmental considerations are becoming increasingly important in the selection and use of big push buttons.

Energy Efficiency

Opting for energy-efficient big push buttons helps in reducing energy consumption. Features like LED indicators can be both visually appealing and energy-saving.

Material and Manufacturing

Considering eco-friendly materials and manufacturing processes can reduce the environmental impact of big push buttons. Some manufacturers might offer sustainable options.

Recycling and Disposal

Proper recycling and disposal of big push buttons at the end of their lifecycle minimize waste and contribute to environmental conservation.

In the world of big push buttons, options are abundant, and understanding various aspects like types, installation, maintenance, customization, safety, technology integration, comparison with other buttons, and environmental considerations is essential. Whether it’s for industrial control, gaming, or creative projects, big push buttons offer functionality, aesthetics, and innovation. From the big red button website to specialized suppliers, resources are readily available to explore and choose the right big push buttons for any application.

Big push buttons are generally reliable, but like all mechanical devices, they may face issues. Here’s how to troubleshoot some common problems.

If a big push button is not responding, check the wiring connections and ensure they are secure. Inspecting the contacts for any dirt or damage and cleaning or replacing them if necessary can also solve the issue.

A button that sticks when pressed might have a mechanical issue. Lubricating the moving parts or replacing worn components may fix the problem.

LED Indicator Not Working

If the big push button has an LED indicator that’s not working, it might be a problem with the LED itself or its connections. Testing the LED with a multimeter and replacing it if needed should resolve the issue.

A button that generates false signals might have a sensitivity issue. Adjusting the sensitivity settings, if available, or consulting the manufacturer’s guidelines can help in resolving the problem.

The evolution of big push buttons reflects technological advancements and changing needs.

From Simple to Complex Designs

Big push buttons have evolved from simple mechanical switches to complex designs with integrated technology. Modern buttons may include features like LED indicators, customizable labels, and wireless connectivity.

Integration with Digital Technology

The integration of big push buttons with digital technology has expanded their applications. They can now be used to control software, interact with microcontrollers, and more.

Focus on Aesthetics

Modern big push buttons are not just functional but also aesthetically pleasing. The availability of various colors, shapes, and custom designs has added to their appeal.

Emphasis on Safety and Standards

Over time, the focus on safety and compliance with standards has increased. Modern big push buttons are designed with safety features and adhere to relevant regulations.

Big push buttons offer exciting opportunities for DIY enthusiasts. Here’s how to experiment with them.

Building Custom Control Panels

Big push buttons can be used to build custom control panels for home automation, gaming, or other interactive projects.

Creating Interactive Art

Artists and hobbyists can use big push buttons to create interactive art installations that engage audiences in unique ways.

Designing Themed Gadgets

Themed gadgets like a “big red button” that performs a specific task can be a fun project. It can be used for practical purposes or simply as a novelty item.

Teaching and Education

Big push buttons can be used in educational projects to teach concepts like circuits, programming, and design. They are engaging tools for both students and educators.

Conclusion

Big push buttons are versatile devices with applications ranging from industrial control systems to arcade games and DIY projects. Understanding their types, functionality, customization options, safety considerations, technological integration, and creative uses provides a comprehensive insight into these fascinating components.

Whether it’s troubleshooting common issues, exploring their evolution, or experimenting with them in DIY projects, big push buttons offer endless possibilities. Their combination of functionality, aesthetics, and innovation makes them an essential part of modern technology and design.

From the huge red button for specific projects to the big red button clicker for gaming, options are abundant. Resources like Indicator Light offer a wide range of big push buttons to explore and choose the right ones for any application, ensuring that the right choice is made to suit specific needs and preferences.

The comprehensive guide to big push buttons aims to be a valuable resource for professionals, hobbyists, and anyone interested in these unique devices. With proper understanding and creativity, big push buttons can be more than just switches; they can become integral parts of innovation and design.