Rocker Toggle Switch: An In-Depth Guide to Understanding and Using Toggle Switches

Rocker toggle switches are integral components used across various industries and applications, ranging from automotive control to home automation and industrial machinery. They come in many forms, including round rocker switches, heavy-duty toggle switches for 12v or 120v systems, and even specialized designs like 2-way toggle switches. This comprehensive guide explores different types of rocker toggle switches, their functions, installation procedures, safety considerations, maintenance tips, troubleshooting, and a glimpse into their future. Whether you’re a hobbyist, a professional, or someone curious about these versatile switches, this article offers valuable insights that will guide you in selecting, using, and understanding rocker toggle switches in depth. Read on to uncover the world of these essential electrical devices.

1.What Is a Rocker Toggle Switch?

- A rocker toggle switch, also known as a round rocker switch or on-off toggle switch, is a mechanical device used to control the flow of electricity in a circuit. Here are three perspectives on what makes this switch unique:

- Design Perspective: The rocker toggle switch is distinguished by its rocker shape, making it easy to use with a simple rocking motion. These switches are available in various styles, including heavy duty toggle switches 12v and round rocker switch on/off/on.

- Functionality Perspective: This switch allows the user to control electrical devices with a flick of a finger. It’s commonly used in automotive, industrial, and household applications.

- Manufacturing Perspective: Rocker toggle switches are designed with robust materials, ensuring durability and reliability in various operating environments.

2.How Does a Rocker Toggle Switch Work?

Understanding how a rocker toggle switch functions is crucial for its proper usage. Here are three points of view:

- Mechanical Perspective: A rocker toggle switch works by moving an internal lever to either close or open the electrical circuit. This movement can be either two-way (on-off) or three-way (on-off-on).

- Electrical Perspective: The switch allows or restricts the flow of current. When the rocker is toggled to the “on” position, the circuit is completed, and the electricity flows through. Conversely, when toggled to the “off” position, the circuit is broken, stopping the flow of electricity.

- User Perspective: From a user’s viewpoint, the rocker toggle switch provides a straightforward method to control electrical devices, such as turning lights on and off or switching between different electrical modes.

3.Types of Rocker Toggle Switches

Rocker toggle switches come in various types, catering to different needs and applications. Here are three insights:

- Based on Voltage: There are heavy-duty toggle switches designed for both low voltage (12v) and high voltage (120v) applications, providing flexibility for different electrical systems.

- Based on Function: Round rocker switch on/off/on, 2-way toggle switch, and industrial toggle switch are some of the functional categories that fulfill specific requirements.

- Based on Industry: From automotive to household appliances, different types of rocker toggle switches are tailored for various industrial applications. For more on this topic, you can explore here.

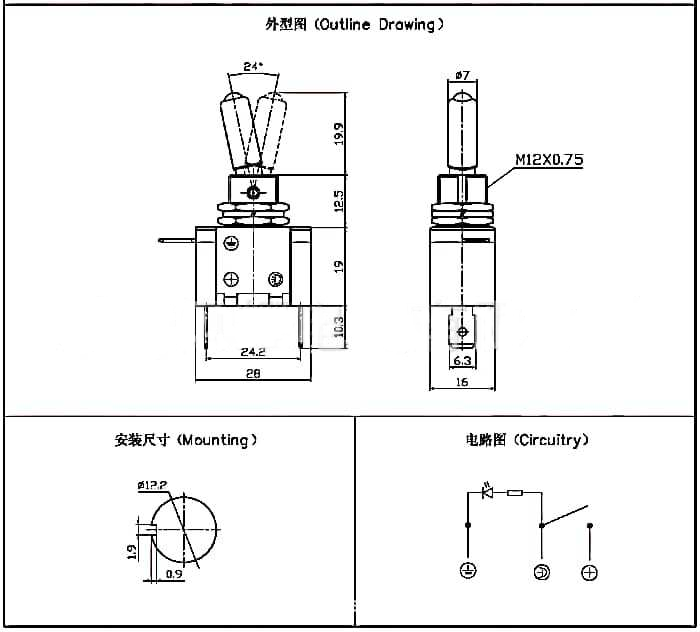

4.How to Install a Round Rocker Switch On/Off/On?

Installing a round rocker switch on/off/on may seem daunting, but it’s a straightforward process with proper guidance. Here are the three angles to consider:

- Preparation Perspective: Ensure that the power is turned off before installation. Gather necessary tools and the round rocker switch on/off/on that suits your application.

- Installation Perspective: Connect the wires to the appropriate terminals, usually marked as ground, power, and load. Secure the switch in the desired location.

- Testing Perspective: After installation, test the switch to make sure it’s working correctly. This involves toggling the switch to each position and verifying that the connected device responds appropriately.

5.Where to Use a Heavy Duty Toggle Switch 12v?

Heavy duty toggle switch 12v has a variety of applications. Three different perspectives on where to use these switches are:

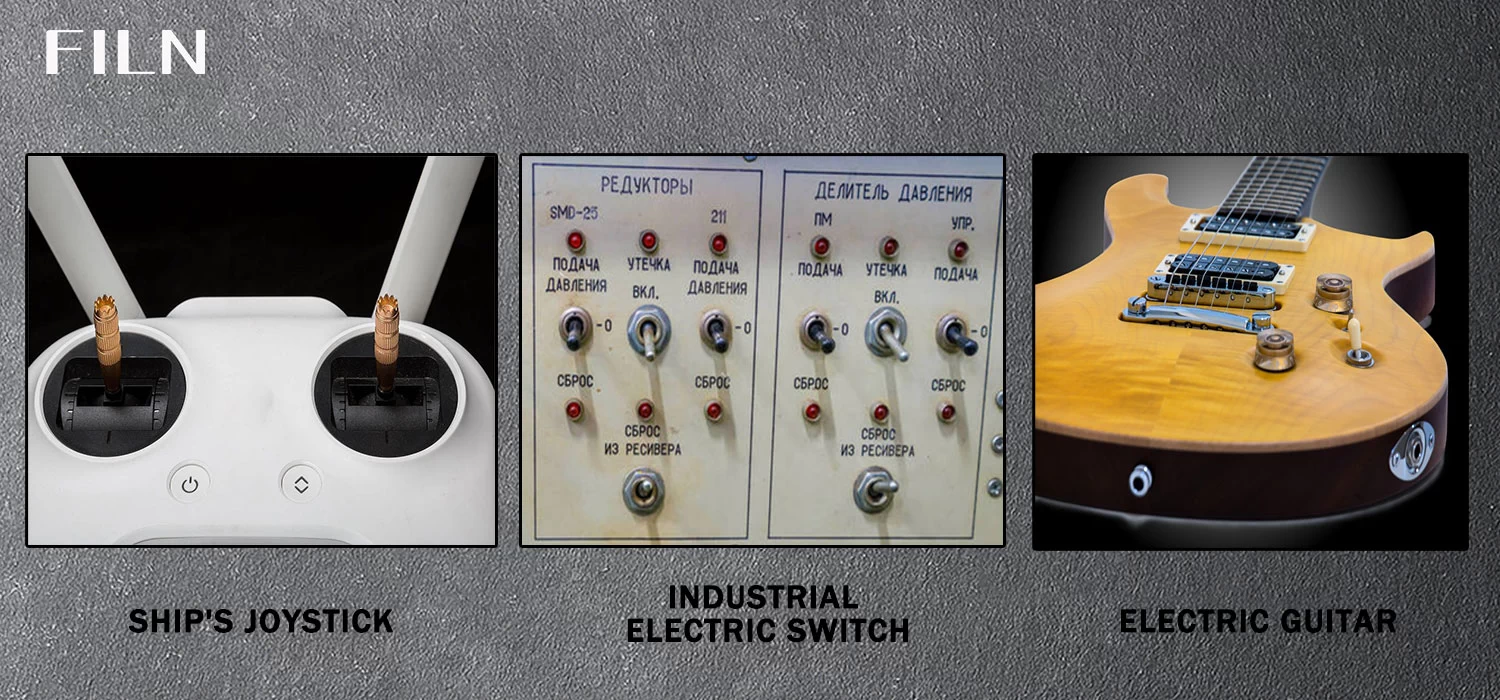

- Automotive Perspective: They are widely used in cars, trucks, and boats to control lights, fans, and other electrical devices.

- Industrial Perspective: In industrial settings, these switches are used for controlling machinery and equipment, requiring 12v power.

- Consumer Electronics Perspective: They are also found in various consumer electronics, like power supplies and computer peripherals.

6.What Are the Applications of a Heavy Duty Toggle Switch 120v?

The heavy duty toggle switch 120v has distinct applications compared to its 12v counterpart. Here are three views:

- Home Appliances Perspective: This switch is used in household appliances that require 120v, like ovens, washing machines, and air conditioners.

- Commercial Perspective: In commercial buildings, they can control lighting, HVAC systems, and more.

- Industrial Perspective: These switches are used in industrial equipment requiring higher voltage, ensuring safety and efficiency.

7.Why Choose a Round Toggle Switch?

Round toggle switches are popular for their design and functionality. Three reasons to choose them are:

- Aesthetic Perspective: Their sleek and modern design makes them appealing in various applications.

- Functionality Perspective: Round toggle switches are versatile and can be used in a multitude of settings, including vehicles and home appliances.

- Availability Perspective: They are widely available in different specifications, allowing users to find the perfect fit for their needs.

8.How to Select an Industrial Toggle Switch?

Choosing the right industrial toggle switch requires consideration of various factors. Here’s a look from three angles:

- Requirement Perspective: Understanding the specific needs of your industrial application, such as voltage, current rating, and functionality, is crucial.

- Quality Perspective: Opt for a reputable manufacturer or supplier, like Indicator Light, to ensure quality and compliance with standards.

- Budget Perspective: Consider your budget without compromising on essential features and quality.

9.2-Way Toggle Switch Vs. 3-Way Toggle Switch

Comparing 2-way toggle switch vs. 3-way toggle switch provides insights into their functionalities. Here are three viewpoints:

- Functionality Perspective: A 2-way toggle switch functions as a simple on-off switch, while a 3-way toggle switch can control the flow of electricity in multiple directions, typically on-off-on.

- Application Perspective: 2-way switches are often used for straightforward applications like light control, while 3-way switches find use in more complex scenarios.

- User Preference Perspective: The choice between these two depends on user preference and specific requirements, providing flexibility in various applications.

10.Understanding ON-OFF Toggle

Switch Functions ON-OFF toggle switches are among the simplest yet essential types of switches. Here’s a closer look from three angles:

- Basic Function Perspective: These switches have two positions: ON and OFF. They either allow the flow of electricity (ON) or stop it (OFF).

- Application Perspective: ON-OFF toggle switches are used in various applications like lamps, machines, and more, providing simple control.

- Variation Perspective: These switches can be found in different forms, including round rocker switch and heavy-duty versions, allowing for customization based on needs.

11.Safety Considerations for Using a Toggle Switch

Safety is paramount when using any electrical device, including toggle switches. Here are three vital considerations:

- Installation Perspective: Proper installation by following the manufacturer’s guidelines and local regulations ensures safe operation.

- Maintenance Perspective: Regular inspection and maintenance can prevent malfunctions and potential hazards.

- User Awareness Perspective: Educating users on proper usage and potential risks helps in preventing accidents and ensuring a safe experience with toggle switches.

By understanding the various aspects of rocker toggle switches, including types, functions, and safety, users can make informed decisions and utilize these switches in numerous applications. The insights provided here cover various perspectives, including design, functionality, installation, and safety, offering a comprehensive guide for anyone interested in rocker toggle switches.

12.Rocker Toggle Switches in the Automotive Industry

Rocker toggle switches have found extensive use in the automotive sector. Here’s a detailed look at their application from three angles:

- Vehicle Control Perspective: They are used to control various vehicle functions like headlights, fog lights, and wipers.

- Customization Perspective: Car enthusiasts often use heavy-duty toggle switches 12v for custom lighting and accessories.

- Manufacturing Perspective: Automotive manufacturers prefer these switches due to their reliability and ease of use, including the heavy duty toggle switch 120v for larger vehicles.

13.Selecting Rocker Toggle Switches for Home Automation

Home automation is becoming increasingly popular, and rocker toggle switches play a vital role. Three perspectives on their selection are:

- Compatibility Perspective: Ensure that the switches are compatible with the home automation system, be it a round toggle switch or a 2-way toggle switch.

- Design Perspective: Choose switches that complement the interior design and aesthetics of the home.

- Functionality Perspective: Consider the functionalities needed, such as dimming lights or controlling fans, and select switches that meet these requirements.

14.Rocker Toggle Switches in Industrial Equipment

The industrial sector relies heavily on rocker toggle switches for various applications. Here are three views:

- Machinery Control Perspective: These switches are used in industrial machinery for operations like starting, stopping, and speed control.

- Safety Perspective: Industrial toggle switches, like the heavy-duty toggle switch 120v, are designed with safety features to prevent accidents.

- Maintenance Perspective: Regular maintenance and proper selection, such as using an industrial toggle switch where required, ensure smooth operation and longevity.

15.Tips for Cleaning and Maintaining Rocker Toggle Switches

Keeping rocker toggle switches clean and well-maintained is essential for their longevity. Here are three tips:

- Cleaning Perspective: Use a soft cloth and mild cleaning agents suitable for the material to avoid damage.

- Inspection Perspective: Regularly inspect switches for any signs of wear, damage, or malfunction.

- Professional Maintenance Perspective: For complex systems, especially industrial applications, seek professional maintenance services to ensure optimal performance.

16.How to Troubleshoot Common Issues with Rocker Toggle Switches

Rocker toggle switches, like any other electrical component, may face issues. Here’s how to troubleshoot them from three perspectives:

- Visual Inspection Perspective: Check for visible signs of damage, wear, or loose connections.

- Testing Perspective: Use a multimeter to test for continuity and ensure the switch is functioning as it should.

- Replacement Perspective: If the switch is faulty and beyond repair, replacing it with a compatible model is usually the best solution.

17.The Future of Rocker Toggle Switches

Looking towards the future, rocker toggle switches continue to evolve. Here’s a glimpse from three viewpoints:

- Technology Perspective: With advancements in technology, we can expect smarter, more efficient switches, possibly with touch or voice control.

- Sustainability Perspective: Future switches may focus on eco-friendly materials and energy-saving features.

- Market Perspective: The growing demand in various sectors, including automotive and home automation, will likely drive continuous innovation and development in the field of rocker toggle switches.

Conclusion

Rocker toggle switches are essential components in various applications, including automotive, industrial, and home automation. Understanding their types, functionalities, installation procedures, and safety considerations can greatly assist in their effective usage. From basic on-off toggle switches to more complex heavy-duty toggle switches 12v or 120v, this comprehensive guide covers multiple perspectives. Whether you’re a homeowner looking to add convenience or an industry professional seeking robust solutions, this guide provides insights and directions on selecting and using rocker toggle switches. Explore more about these switches and their various applications at Indicator Light.