In high-stakes industrial environments, safety is not merely a priority—it is the bedrock of operation. The difference between a minor incident and a catastrophic failure often rests on the reliability of one crucial component: the Emergency Stop Button. Today, we delve into the superior features and applications of the 22mm Metal Emergency Stop Button, a device engineered for maximum durability, reliability, and security in the most challenging settings.

The Foundation of Reliability: Why Choose a 22mm Metal Emergency Stop Button?

When selecting an E-stop, materials matter. Plastic alternatives simply cannot withstand the continuous impact, chemical exposure, or rough handling inherent in Industrial Heavy Duty E-stop applications. Our featured component, the 22mm Metal Emergency Stop Button, offers a robust construction that sets it apart. The metal body ensures resistance to physical shock and corrosion, making it the go-to solution for factory floors, heavy machinery, and processing plants.

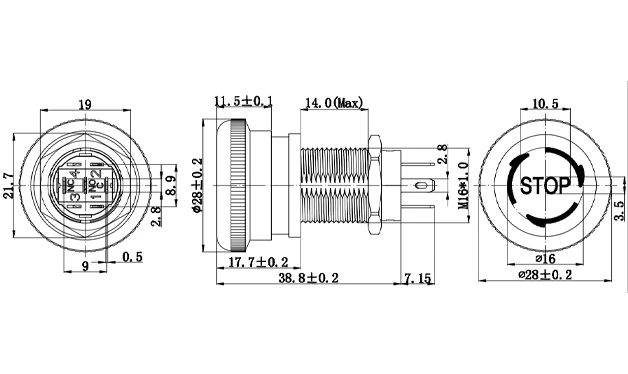

This specific model is designed for a precise 22mm Panel Mount Safety Switch installation, a standard size that allows for easy integration into existing control panels, machinery consoles, and junction boxes. The standard mounting size streamlines installation and maintenance, minimizing downtime during upgrades.

Design Excellence: The Rugged Mushroom Head Switch

The iconic mushroom head design is universally recognized as the standard for emergency controls, offering a large, easily accessible surface area. However, not all mushroom heads are created equal. This E-stop features a Rugged Mushroom Head Switch that is not only visually prominent in its bright red color (as required by safety regulations) but is also built from hardened metal.

The combination of the durable metal construction and the highly visible, large surface area provides two key benefits:

-

Rapid Activation: In an emergency, operators can activate the switch instantly and accurately, even while wearing heavy-duty gloves.

-

Unmatched Durability: It can withstand repeated, forceful strikes without degradation, fulfilling the true requirement of an Industrial Heavy Duty E-stop.

Technical Deep Dive: Latching and Connection Specifications

Understanding the technical parameters is essential for seamless system integration. This 22mm Metal Emergency Stop Button utilizes a vital mechanism: 22mm Latching Push Button Metal.

-

Latching Mechanism: Latching means the button, once depressed, remains in the “off” (activated) position until it is manually reset. The rotation of the metal head serves as the reset function—a crucial detail for compliance with safety standards, as it prevents accidental or premature machine restart. The Rotary Release mechanism is simple, intuitive, and highly dependable.

-

Connection Type: This model is equipped with a 3-Pin Connector. This standard configuration typically supports a normally closed (NC) contact block (required for E-stop functionality) and provides secure, reliable wiring connections, ensuring the control signal is not lost due to vibration or environmental stress.

The Advantage of Strength: Vandal Resistant Emergency Switch

A significant selling point of any metal switch is its inherent strength, which translates directly into superior protection. In environments where equipment is accessible to a wide range of personnel, or in public-facing applications (such as transportation hubs or public utility stations), the need for a Vandal Resistant Emergency Switch is paramount.

The metal construction of the 22mm Metal Emergency Stop Button makes it highly resistant to tampering, breakage, and deliberate damage. It’s an essential feature for maintaining system integrity and operational safety, especially in unsupervised or high-traffic areas. The robust metal housing deters misuse and ensures the emergency function remains operational when it is most needed.

Summary of Key Features for Your Next Safety Implementation

| Feature | Specification | Safety/Operational Benefit |

|---|---|---|

| Mounting Diameter | 22mm | Standard Panel Mount Safety Switch size for easy integration. |

| Head Type | Red Mushroom | Highly visible and easy to activate; Rugged Mushroom Head Switch design. |

| Material | Metal Alloy | Industrial Heavy Duty E-stop rating; Vandal Resistant Emergency Switch capability. |

| Operation | Latching Push / Rotary Reset | Ensures the machine remains stopped until deliberately reset (22mm Latching Push Button Metal). |

| Connection | 3-Pin Plug-in | Secure, quick, and reliable wiring connection. |

Conclusion: Investing in the Ultimate Safety Component

The 22mm Metal Emergency Stop Button is more than just a switch; it is an investment in uncompromising safety. It satisfies the rigorous demands of modern industrial safety protocols through its metal durability, reliable latching operation, and globally standard design.

For procurement managers seeking Industrial Heavy Duty E-stop components, or engineers designing safety-critical control panels, choosing this 22mm Metal Emergency Stop Button guarantees peace of mind. Its features—from the Rugged Mushroom Head Switch to its capabilities as a Vandal Resistant Emergency Switch and reliable 22mm Latching Push Button Metal—make it the ultimate choice for critical machinery shut-down. Ensure your operations are protected with the best in class.

FAQS

Q1: What makes the metal version better than a standard plastic E-stop, especially for factory use?

A1: The metal construction is engineered for Industrial Heavy Duty E-stop applications. Unlike plastic, the metal housing provides superior resistance to impact, vibration, temperature extremes, and chemical exposure commonly found on factory floors. This enhanced durability also qualifies it as a robust Vandal Resistant Emergency Switch, ensuring reliability in harsh environments.

Q2: Is this a momentary or a latching switch?

A2: This model is a 22mm Latching Push Button Metal switch. This means that once the button is pressed (activated), it stays in the “off” state until it is manually reset by rotating the head. This is a critical requirement for safety applications, as the machine cannot restart accidentally.

Q3: How is the E-stop released once it is activated?

A3: The emergency switch features a metal Rugged Mushroom Head Switch that uses a Rotary Release mechanism. After the button is pushed and latched, the operator must deliberately twist the red mushroom head to unlatch the mechanism and restore the system to its operational state.

Q4: What is the significance of the 22mm mounting size?

A4: The 22mm Panel Mount Safety Switch dimension is a global industrial standard. This ensures that the 22mm Metal Emergency Stop Button can be easily and quickly installed into almost any existing control panel, machine console, or standard push-button enclosure without the need for custom fabrication.

Q5: Can the 3-Pin connector be used for both Normally Closed (NC) and Normally Open (NO) circuits?

A5: The 3-Pin Connector typically accommodates one set of contacts, which, for emergency stops, is almost always wired as Normally Closed (NC). This ensures that if the wire is cut or the circuit is broken, the machinery will immediately stop (fail-safe operation). You should always check the included contact block configuration to ensure it meets your specific safety requirements.