Introduction

In the world of industrial safety, the emergency stop push button is a small yet crucial component. It stands as a sentinel, ready to halt operations instantly to prevent accidents and injuries. One particular design that stands out is the illuminated emergency stop push button with a mushroom head profile, metal construction, and a 16mm size. This article delves into the intricacies of this essential safety device, exploring its features, benefits, and applications.

Component Material:

| Component Name | Material |

|---|---|

| Light Guide Button | PC Plastic |

| Button | Aluminum Alloy (Red Oxidized Surface) |

| Outer Shell | PC Plastic |

| Button Pin | H62 Nickel Plated Brass |

| Waterproof Ring | Rubber Ring |

| Nut | PC Plastic |

| Housing | PBT (High-Temperature Resistant) |

| Light Source | – |

| Resistor | – |

Performance Parameter:

| Items | Parameter | Value |

|---|---|---|

| Switch Rated Voltage | Rated Voltage | 36V DC |

| 250V AC | ||

| Switch Rated Current | Rated Current | 3A DC |

| 3A AC | ||

| Indicator Light Voltage | 12V DC | |

| Indicator Light Current | 10mA | |

| Rated Power | Rated Power | 108W (DC) |

| 750W (AC) | ||

| Insulation and Voltage Resistance | Insulation and Voltage Resistance | 1800V |

| Point Resistance | Point Resistance | ≤50mΩ |

| Isolation Resistance | Isolation Resistance | ≥100MΩ |

| Mechanical Life | 200,000 cycles | |

| Electrical Life | Electrical Life | 100,000 cycles (250V/3A) |

| Operating Temperature | Operating Temperature | -25℃ to +85℃ |

| IP Degree | IP Degree | IP65 |

| IK Rating | IK Rating | IK08 |

| Indicator Light Color | Customizable | – |

What is an Illuminated Emergency Stop Push Button?

An illuminated emergency stop push button is a specialized device designed to provide immediate cessation of machinery operations in emergency situations. The illumination ensures visibility even in low-light conditions, making it easier for operators to locate and activate the button when every second counts. This feature is particularly beneficial in high-risk environments where swift response is critical to safety.

Key Features

- Illuminated Design: Enhances visibility in low-light conditions, ensuring quick identification and operation during emergencies.

- Mushroom Head Profile: Provides a large, easily recognizable surface for fast actuation, reducing response time in critical situations.The mushroom head profile is distinguished by its large, rounded shape, which makes it easily recognizable and accessible. This design is not just for aesthetics; it significantly enhances safety by providing a larger surface area that can be quickly pressed in an emergency. The ergonomic design ensures that even in a panic situation, the button can be activated with minimal effort.

- Metal Construction: Offers robust durability and resistance to wear, ideal for harsh industrial settings.Constructed from durable metal, these push buttons are built to withstand harsh industrial environments. The metal construction provides robustness, ensuring that the button can endure frequent use and rough handling without compromising its functionality. This durability translates to a longer lifespan, making it a cost-effective safety solution.

- 16mm Mounting Diameter: Compact size allows for easy integration into control panels with limited space.Why 16mm? The 16mm size strikes a balance between compactness and usability. It is small enough to be integrated into various control panels and systems without requiring extensive modifications. Yet, it is large enough to be easily operated, ensuring that it is effective in emergency situations. This size also makes it compatible with a wide range of industrial and commercial equipment.

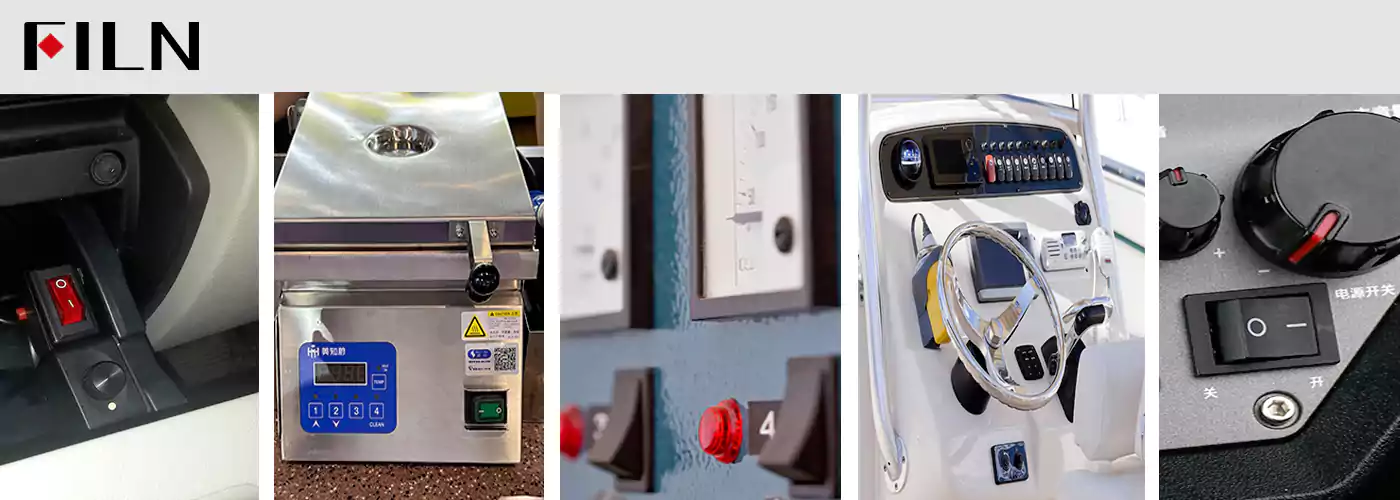

Applications of Illuminated Emergency Stop Push Buttons

These push buttons find applications across diverse sectors. In industrial settings, they are used on machinery to provide an immediate stop mechanism in case of malfunction or danger. Commercially, they are found in places like elevators and public transport systems, ensuring passenger safety. They are integral to safety protocols in environments ranging from manufacturing floors to amusement parks.

- Industrial Machinery: Ensures the safety of operators by providing a quick and reliable method to stop machinery during emergencies.

- Commercial Equipment: Commonly used in elevators, escalators, and other automated systems to prevent accidents.

- Automated Systems: Integral part of safety circuits in automated manufacturing and processing plants.

Benefits

- Enhanced Safety: The illuminated feature ensures the button is easily visible, reducing the risk of accidents.

- Easy Installation: The 16mm mounting diameter is a standard size, making it compatible with most control panels.

- Durability: The metal construction ensures long-lasting performance even in demanding environments.

- User-Friendly: The large mushroom head design allows for quick and effortless operation.

Emergency Stop Push Button FAQ

- What makes the mushroom head design unique?

- The mushroom head design provides a larger surface area, making it easier to press in emergencies. Its ergonomic shape ensures quick and efficient activation.

- How does illumination improve safety?

- Illumination improves visibility, especially in low-light conditions, ensuring the button can be easily located and activated swiftly in an emergency.

- Can I retrofit this push button into existing systems?

- Yes, the 16mm size makes it compatible with various control panels and systems, allowing for easy retrofitting without extensive modifications.

- What are the maintenance requirements?

- Regular inspections, cleaning, and testing are essential to ensure the button remains functional. Checking for wear and securing wiring connections can prevent potential issues.

- Are there wireless options available?

- Some modern emergency stop push buttons come with wireless connectivity, allowing for remote monitoring and control, adding an extra layer of safety and convenience.