Rocker Light Switch On Off Position: An In-Depth Guide

Rocker light switch on off position is a versatile and vital component in numerous applications, from simple household uses to complex industrial machines. This article provides an in-depth guide to understanding ON/OFF rocker switches, exploring their various types, how to select the right one for your needs, the different wiring configurations, quality considerations, maintenance tips, and troubleshooting common problems. Whether you are a professional looking to enhance your knowledge or a beginner seeking guidance, this extensive guide offers valuable insights into the world of rocker switches. Continue reading to unlock the potential of these essential devices.

An understanding of the rocker light switch on off position is essential for various applications. This article will answer the most common questions regarding ON/OFF rocker switches, their usage, specifications, and more, covering all related aspects.

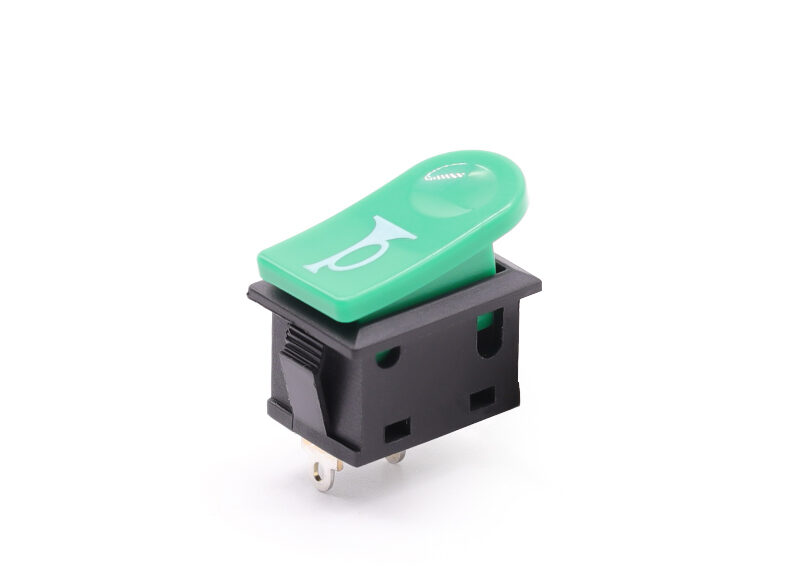

Product Parameters:

| Product Item | FL3-KCD5 |

| Contact Way | solder pin |

| Install Way | Buckle |

| Lamp Type | LED |

| Rated voltage | 125V,250V |

| Lamp Color | Red,white,blue,green,black,yellow |

| Shell Material | brass plated nickel |

| Base Material | PA66 nylon |

| Terminal Material | brass |

| Applications | Coffee machine, kitchen equipment, household appliances, automobiles, medical equipment, industrial equipment etc |

| Current | 6A,15A |

Related products:

What is the Correct Rocker Light Switch On Off Position?

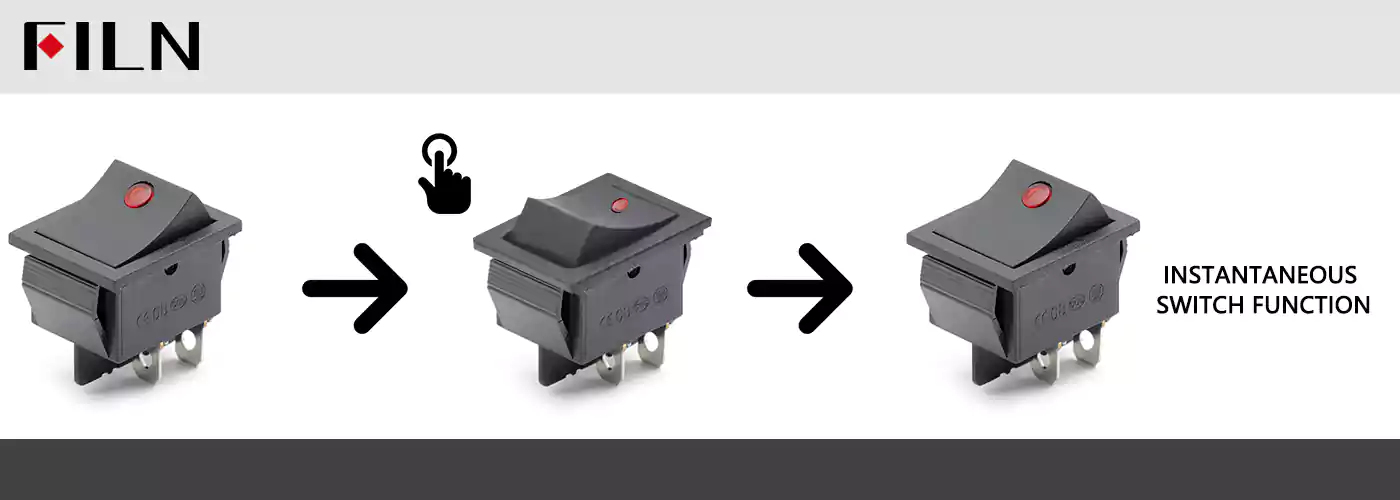

Understanding Correct Rocker Light Switch On Off Position States

Rocker switches are designed to perform switching operations by moving between two or more positions. The rocker switch state synchronous refers to the alignment and coordination of these positions. You can find detailed information on these switches at Indicator Light.

How to Determine the Rocker Light Switch On Off Position

Usually, the ON/OFF rocker switches are labeled to indicate their positions. The “ON” position is commonly towards the top or right, while the “OFF” is towards the bottom or left. This position can vary depending on the design and manufacturer, and a detailed look into the switch specifications is advisable. Find more information at this link.

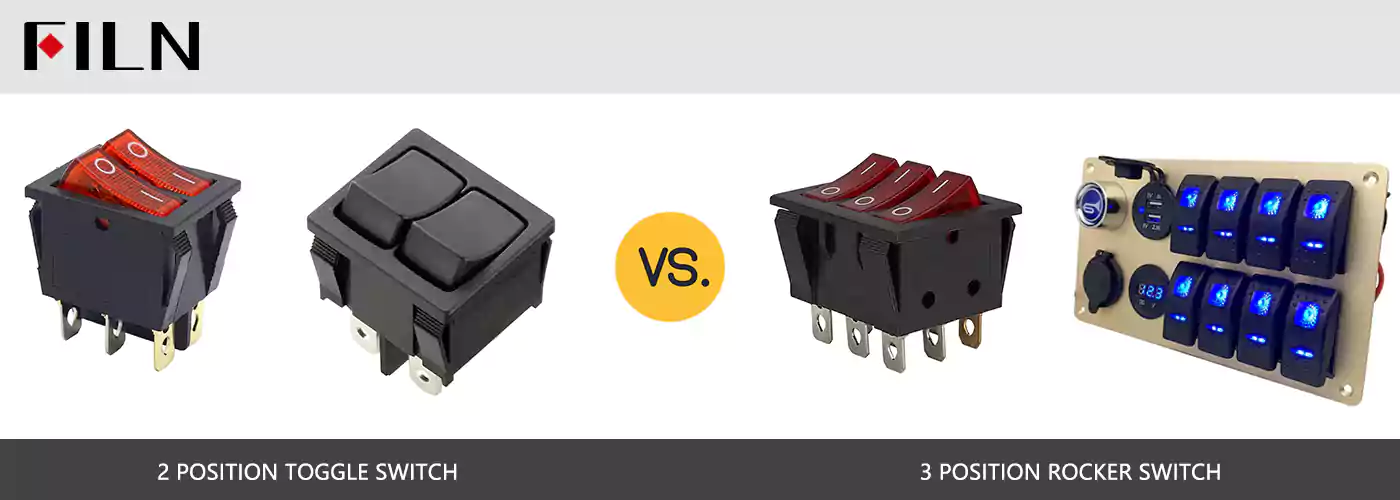

Rocker Light Switch On Off Position in Multi-State Switches

Multi-state rocker switches, such as ON-OFF-ON switches, may have additional rocker light switch on off position. The synchronous position refers to the alignment of these states in a way that ensures smooth switching. A deeper look into on-off-on rocker switch wiring diagrams might provide better clarity.

How to Identify the Rocker Light Switch On Off Position?

Basics of Horizontal Light Switches

Horizontal light switches are often used in modern interiors. Identifying the ON/OFF position might seem confusing, but it’s relatively simple. More on horizontal switches can be found at KCD3 Switch.

Indicators for ON/OFF Position

Some horizontal switches come with indicators or labels to guide users. However, if no label is present, you may need to refer to the user manual or the manufacturer’s website.

Customizing Horizontal Rocker Light Switch On Off Position

Horizontal rocker switches can also be customized to suit preferences or specific needs. Knowing the standard ON/OFF orientation can help in installation or configuration processes.

How to Wire an ON-OFF-ON Rocker Switch?

Understanding ON-OFF-ON Configuration

An ON-OFF-ON rocker switch has three positions and is often used to control two separate circuits. This unique configuration allows the user to switch between two circuits without turning the switch off.

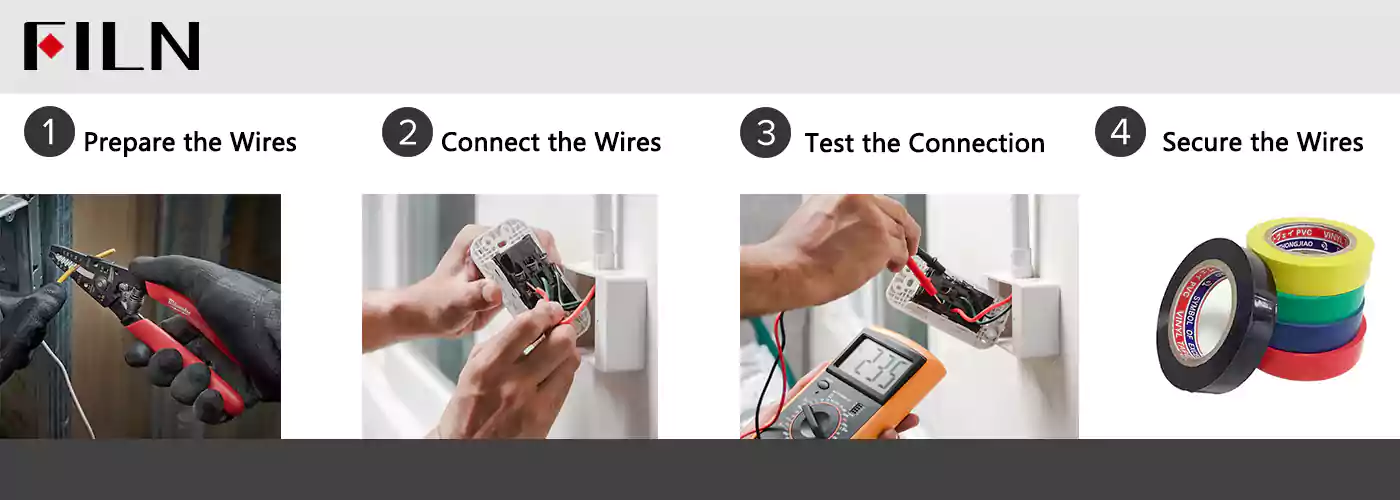

Wiring Diagram and Process

An on-off-on rocker switch wiring diagram will provide step-by-step instructions for the wiring process. Ensuring the correct wiring is vital for the proper functioning of the switch. You can find specific wiring diagrams for ON-OFF-ON switches at KCD4 Switch.

Safety Considerations

When wiring an ON-OFF-ON rocker switch, safety precautions must be taken. Working with a certified electrician or following the manufacturer’s instructions carefully can prevent any mishaps.

What Is a Rocker Light Switch On Off Position Used For?

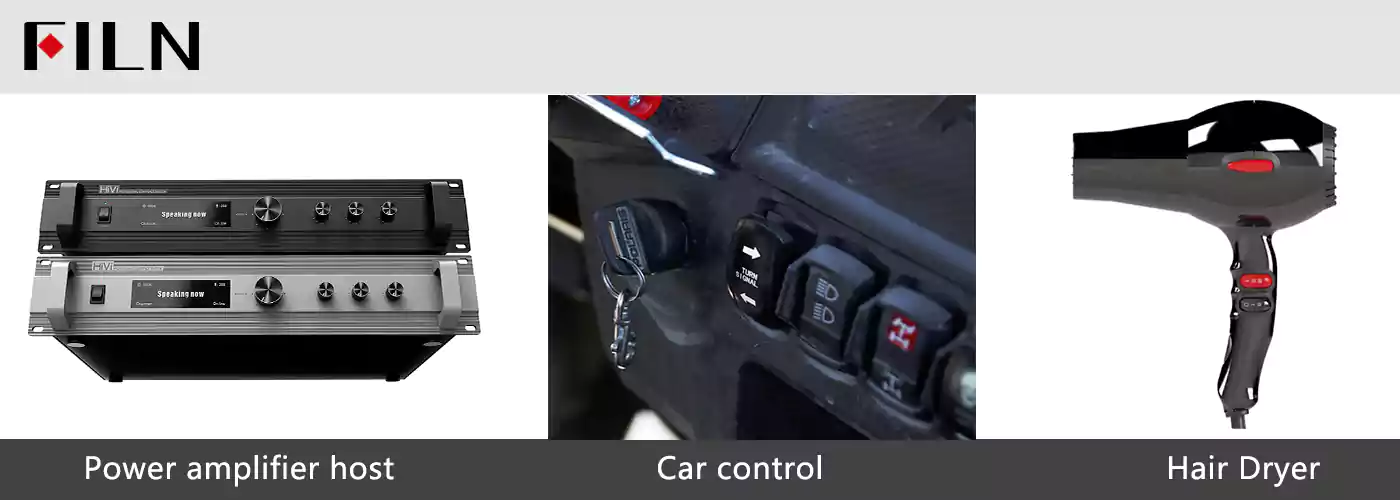

Applications in Electronics

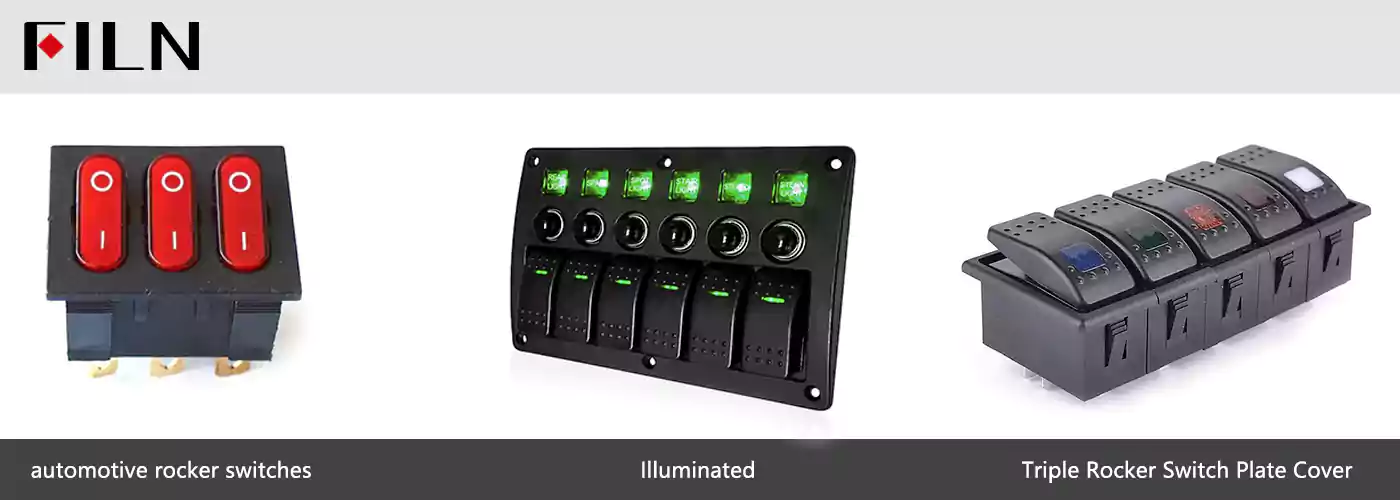

Rocker switches are used in various electronic devices such as computers, power supplies, and kitchen appliances. Their simplistic design and ease of use make them suitable for these applications.

Use in Automotive Industry

ON/OFF rocker switches find applications in the automotive industry to control lights, wipers, and other functionalities. Their robust design ensures reliable performance.

Home and Industrial Usage

Rocker switches are also used in home automation systems and industrial machinery. Their design can withstand constant use, making them suitable for demanding environments.

What Are the Different Types of Rocker Light Switch On Off Positions?

Standard Rocker Switches

Standard rocker switches are commonly used in household appliances. They are easy to operate and come in various designs. More details on standard switches can be found at KCD1 Switch.

Waterproof Rocker Switches

Waterproof rocker switches are designed to resist water and moisture, making them suitable for outdoor or marine applications. More on waterproof switches can be found at Waterproof Rocker Switch.

Specialized Rocker Switches

Some rocker switches are specialized for specific applications such as heavy-duty machinery or medical equipment. Understanding the specifications and choosing the right type ensures optimal performance.

What Is a Rocker Switch on a Lamp?

Rocker Switches in Lamps

Rocker switches on lamps provide an efficient way to turn the lamp ON or OFF. They offer a sleek design and are often preferred for modern aesthetics.

Types and Designs

The rocker switch on a lamp can vary in design, size, and functionality. Some may offer dimming capabilities or multiple brightness levels. For a wide range of lamp switches, visit Indicator Light.

Installation and Replacement

Installing or replacing a rocker switch on a lamp can be done with basic tools. Following the lamp’s manual and taking necessary safety precautions ensures a smooth process.

What Are the Key Rocker Switch Specifications?

Electrical Ratings

Electrical ratings such as voltage, current, and resistance are key specifications that define a rocker switch’s capability. These should be considered based on the intended application.

Mechanical Properties

Mechanical properties like size, shape, and material affect the durability and usability of the switch. These specifications should align with the application requirements.

Compliance and Standards

Rocker switch specifications often include compliance with international standards and regulations. Ensuring adherence to these standards guarantees safety and reliability.

What Are the Different Wiring Configurations for Rocker Switches?

Single Pole Single Throw (SPST) Configuration

The SPST configuration is the simplest form of a rocker switch with just two positions, ON and OFF. This type is commonly used in household applications, where a single device needs to be controlled.

Single Pole Double Throw (SPDT) Configuration

SPDT configuration allows the switch to control two different circuits, offering more flexibility. This type of switch has three terminals and is widely used in automotive applications.

Double Pole Single Throw (DPST) Configuration

DPST configuration permits control over two circuits simultaneously with a single switch action. They are utilized in industrial machines or applications where two circuits need to be controlled in sync.

Double Pole Double Throw (DPDT) Configuration

DPDT switches offer even more versatility, controlling two separate circuits with two different positions. This type allows for complex operations and is found in applications like multi-speed motors.

How to Identify the Quality of a Rocker Switch?

Material Quality

The quality of materials used in a rocker switch determines its durability and performance. High-quality plastics and metals often signify a well-made switch.

Compliance with Standards

A quality rocker switch will comply with international standards and regulations. Certifications and testing reports can provide confidence in the switch’s reliability.

Manufacturer Reputation

Choosing a rocker switch from a reputable manufacturer ensures a higher likelihood of quality. Researching reviews or consulting experts in the field may guide a purchase decision.

Warranty and Support

Quality rocker switches often come with warranties and support from the manufacturer. These aspects provide peace of mind and support in case of any issues.

How to Choose the Right Rocker Switch for Different Applications?

Understanding the Application Requirements

Before selecting a rocker switch, understanding the specific requirements of the application is essential. This includes knowing the voltage, current, environment, and functionalities needed.

Assessing Specifications

Rocker switch specifications must align with application requirements. Considerations like electrical ratings, mechanical properties, and compliance are vital.

Consulting Experts or Manufacturers

If in doubt, consulting experts or manufacturers can guide the selection process. They can recommend suitable options based on application needs and their product range.

Evaluating Budget and Quality

Balancing budget constraints with quality is often a critical factor in choosing the right rocker switch. A quality switch that fits the budget ensures satisfaction in the long run.

What Are the Maintenance Tips for Rocker Switches?

Regular Inspection

Regular inspection of rocker switches for wear and tear can prevent unexpected failures. This includes checking for loose connections, signs of overheating, and mechanical wear.

Cleaning and Dusting

Keeping the switches clean from dust and debris ensures smooth operation. Cleaning should be done with appropriate materials and in accordance with the manufacturer’s guidelines.

Replacement of Damaged Parts

If a rocker switch shows signs of damage or malfunction, timely replacement of parts or the entire switch is advisable. Following the correct replacement process ensures safety and proper functioning.

Adhering to Manufacturer’s Guidelines

The manufacturer’s guidelines often include specific maintenance tips and schedules. Adhering to these recommendations keeps the switch in optimal condition.

How to Troubleshoot Common Rocker Switch Problems?

Switch Not Responding

If a rocker switch is not responding, checking the connections and wiring can often resolve the issue. A thorough inspection might reveal a loose connection or a broken wire.

Intermittent Functionality

Intermittent functionality might be due to wear and tear or dust accumulation. Cleaning the switch or replacing worn parts could remedy this problem.

Overheating or Sparking

Overheating or sparking can indicate serious issues like short circuits or incorrect wiring. Immediate professional assistance should be sought to address such problems.

Understanding Common Indicators

Some rocker switches come with built-in diagnostic features or indicators. Understanding these can help in quick troubleshooting and resolution of common problems.

This extensive guide on rocker light switch on off position should cover all aspects of ON/OFF rocker switches, including types, applications, wiring, quality assessment, maintenance, and troubleshooting. Whether you are an electrician, a DIY enthusiast, or simply someone looking to understand these switches better, this article provides a comprehensive resource. Understanding these switches and their functionalities can significantly improve efficiency and safety in various applications.

How To Buy A Rocker Switch ?

You can email us directly, please indicate the information of voltage, current, color, and usage environment.

We can recommend the most suitable rocker switch to you, our email address is inquiry@cnylin.com.cn.

If you need the common rocker switch, such as KCD4 rocker switch, KCD1 waterproof rocker switch, you can click on this link www.cnfiln.com ,you can place an order in our store, we will arrange the delivery within 24 hours.