A terminal block is a versatile electrical connector used for wiring in various industrial applications. By gathering multiple wires into a single connection point, it simplifies complex circuits. Let’s delve into the features, types, and applications of terminal connectors.

What is a Terminal Block?

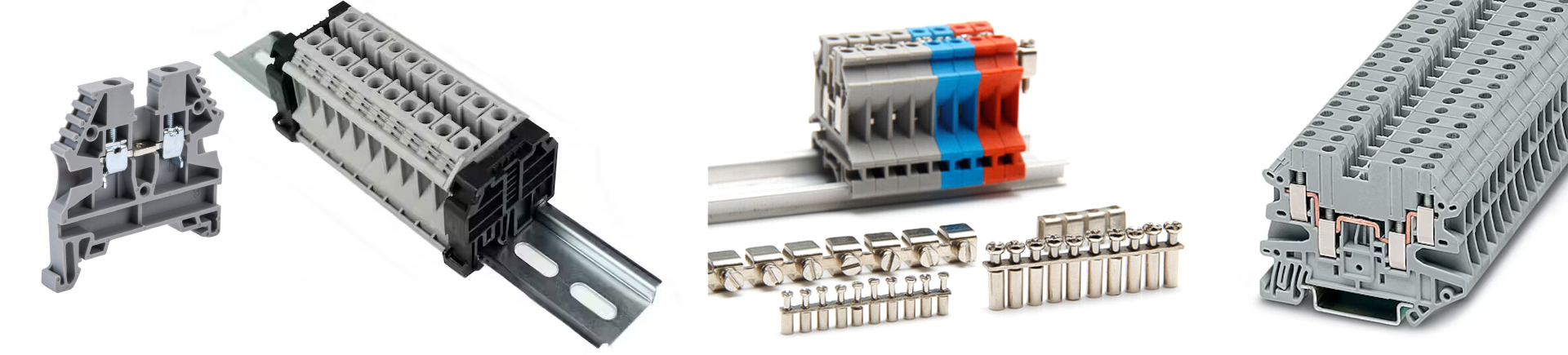

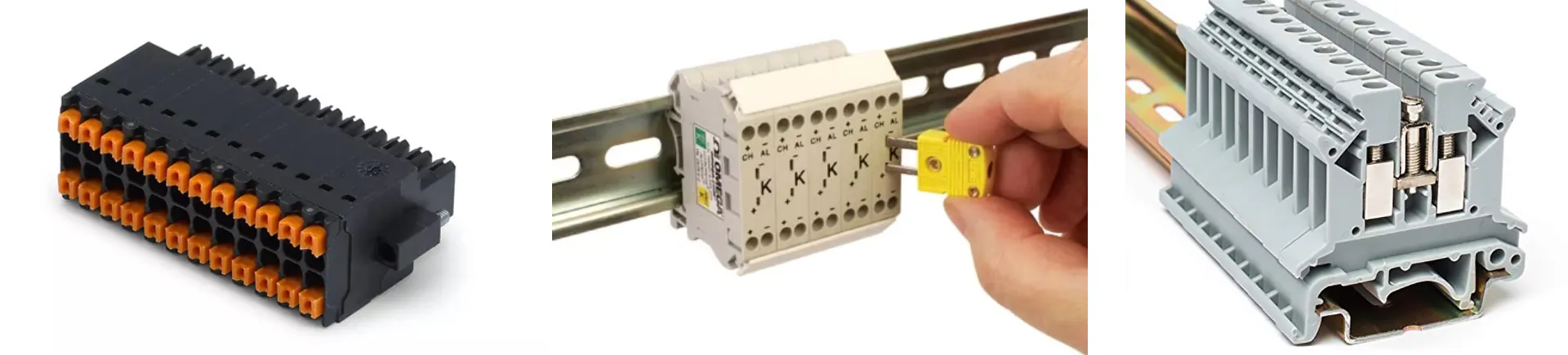

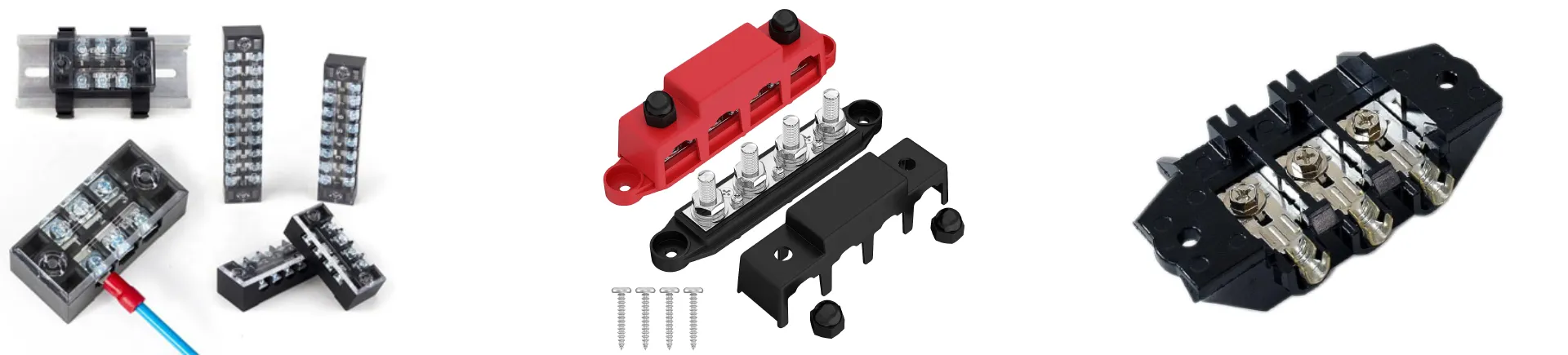

Types of Terminal Blocks

FLUK Series Combined Terminal Blocks: Features and Applications

Overview: The FLUK Series combined terminal blocks employ a frame-type screw connection structure. This design complies with IEC60947-1 and GB14048 standards and is widely used in AC 50Hz (60Hz), rated voltage 660V, DC 40V, and below circuits. It connects conductors with a rated cross-sectional area of 0.75~150mm2. It’s also suitable for connecting round copper conductors with tube terminals without special treatment or pressure welding.

Features of DIN Rail Terminal Blocks:

- Rational Installation Structure DIN rail terminal blocks have extensive universality and can be used on G-type and TH-type guide rails. If the cross-sectional area exceeds 50mm2, fastening accessories are used for mounting.

- Compact Size, Comprehensive Specifications They offer a large conductor cross-sectional area and good electrical conductivity. Those with a cross-sectional area below 50mm2 employ copper press line frames and copper fastening screws. For those above 50mm2, copper press line frames, steel screws, and copper skirts are used. They provide significant tightening torque and self-locking capabilities.

- Powerful Combination Functions Wago terminal blocks make conductor connection much simpler.

The FLUK Series combined terminal blocks meet a variety of electrical connection needs with their powerful features and flexibility. From design to installation, this product showcases high levels of professionalism and reliability, making it an ideal choice for electrical connection solutions.

How to Use a Terminal Block?

Terminal blocks are essential in electrical systems. This guide will teach you how to use a terminal block effectively.

Prepare Types of Terminal Blocks and Required Components

DIN rail terminal blocks, terminal block connectors, and wire blocks are various types of terminal blocks. You will also need terminal block jumpers, a terminal box, and connector blocks.

Steps for Using a Terminal Block

- Prepare the Terminal Box:First, install the terminal block inside a terminal box.

- Choose Connector Blocks:Pick connector blocks that are compatible with your terminal block.

- DIN Rail Installation: If using a DIN rail terminal block, make sure to securely attach it to the DIN rail.

- Connect Wires: Insert the wires into the connector block and tighten the screws.

- Use Terminal Block Jumpers: Jumpers allow you to connect two or more connection points.

- Safety Measures: Turn off the power before making any electrical connections and follow the manufacturer’s guidelines.

Using a terminal block is not complicated. With the right tools and steps, you can efficiently organize and connect your wires. Choose high-quality products to ensure the highest level of safety and performance.

How Do Terminal Blocks Work?

Terminal blocks are pivotal in creating safe, secure, and organized electrical connections. But how exactly do they work? Let’s break it down.

The Basics of Terminal Blocks

A terminal block serves as an interface between different electrical circuits. Its primary function is to connect and isolate electrical paths, allowing for easier modifications or troubleshooting.

Also known as connector blocks, these units enable wire-to-wire and wire-to-board connections. They can easily be customized to suit varying electrical requirements.

Fused Terminal Block

A fused terminal block features built-in fuses for additional safety. It protects the circuit by breaking the electrical path in case of a current overload.

Electrical Block

This is the most basic form of a terminal block, mainly facilitating wire-to-board connections without additional features like fuses.

How Terminal Blocks Function

Wires are inserted into the terminal block and secured by screws or clamps. Connector blocks often come with multiple ports for varied applications.

A terminal block can isolate circuits within a larger electrical system, making it easier to control individual segments.

In fused terminal blocks, the built-in fuse will trip when there’s an overload, thereby safeguarding the connected equipment.

Key Features

- Modularity: Allows for easy addition or removal of connections.

- Safety: Fused terminal blocks add an extra layer of protection.

- Versatility: Connector blocks can be adapted for multiple uses.

Always make sure to turn off the electrical supply and follow safety guidelines when working with terminal blocks. Regular inspections are advised to ensure optimal performance.

Understanding how terminal blocks work helps you make informed decisions for your electrical needs. From connector blocks to fused variants, choosing the right type ensures safety and efficiency in any electrical system.

A Comprehensive Guide to Different Types of Terminal Blocks

Introduction:

When it comes to electrical connections, terminal blocks serve as a versatile and efficient solution. Whether you’re working with a 12v terminal block or a marine terminal block, the options are numerous and tailored to specific needs.

Common Types of Terminal Blocks

Barrier Terminal Blocks:

Barrier terminal blocks are the traditional type, ideal for high-power industrial applications. Their structure aids in the prevention of short circuits.

PCB Terminal Blocks:

PCB terminal blocks enable secure electrical contact and are directly mounted on printed circuit boards. They are compact and best suited for low or moderate power uses.

Phoenix Terminal Blocks:

Renowned for their quality, Phoenix terminal blocks are often the go-to choice for robust applications. They offer excellent reliability and can be found in both commercial and industrial settings.

Power Terminal Blocks:

Specifically designed for high current applications, power terminal blocks come with large-sized screws for robust connections. These are most common in large machinery and industrial setups.

Specialized Terminal Blocks

Marine Terminal Blocks:

These are engineered for harsh marine environments. Marine terminal blocks are corrosion-resistant and ensure long-lasting performance even under tough conditions.

Automotive Terminal Blocks:

Perfect for vehicular applications, these are lightweight yet durable. Automotive terminal blocks are designed to withstand conditions like vibration and heat.

Fuse Terminal Blocks:

Incorporating a fuse into the design, these blocks offer an extra layer of protection against current overload.

Dryer and Stove Terminal Block Screws

These come with specific screws and are particularly useful in household appliances like stoves and dryers.

Other Types

Strip Terminal and Block Connectors:

These are generally for home use or small-scale applications. Strip terminals and block connectors are easy to install and require minimal tools.

Power Distribution Terminal Block and Rail Terminal:

These types are for advanced applications like power distribution. They can hold multiple wires and are usually mounted on a DIN rail for added stability.

Conclusion

From phoenix terminals to power distribution terminal blocks, the market offers a myriad of choices. No matter what your needs are, there’s a terminal block that fits the bill, ensuring secure and efficient electrical connections.

FILN is your comprehensive solution for electrical components. Not only do we offer a wide range of Terminal Blocks to suit your needs, but we also excel in providing tailored manufacturing services for Indicator Lights, Push Button Switches, and Rocker Switches. With FILN, you can simplify your procurement process and find everything you need under one roof.

Our commitment to customer satisfaction extends beyond just supplying high-quality products. We are dedicated to helping you achieve your specific requirements, and our team is readily available to assist you with any custom design or configuration. Your satisfaction is our priority, and we’re here to ensure that your purchasing experience is as seamless as possible.

If you have any inquiries or need assistance with your purchasing plans, please don’t hesitate to reach out to FILN. We are here to support you in finding the perfect solutions for your electrical component needs. Contact us today, and let’s start a conversation about how FILN can elevate your projects.