Flick Switches: Comprehensive Guide and FAQ

Flick Switches: Comprehensive Guide and FAQ

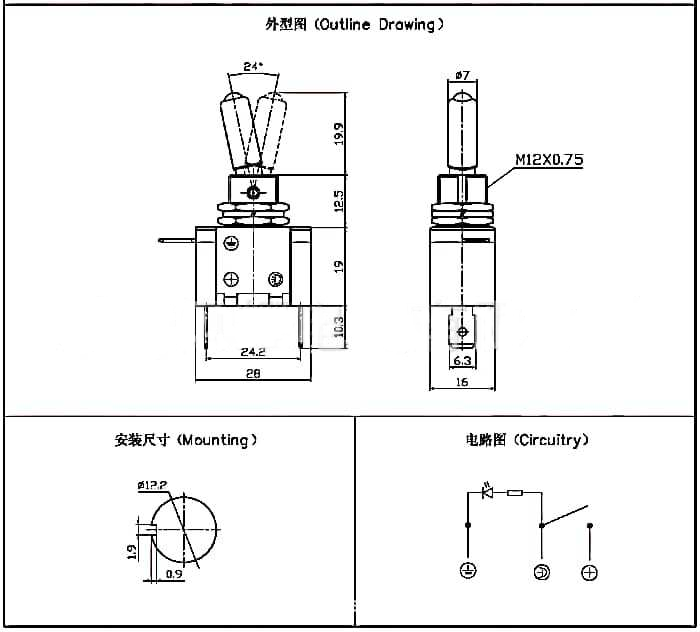

- Model:2 prong 12v Toggle Switch

- Name:flick switches

- Working Voltage: < 250V

- Electric Current:20A

- Contact:Open/Closed

- Voltage:250V

- Life:50000 times

- Specifications: 2 pin 2 positions

- Email:inquiry@cnylin.com.cn

- Website:www.FILN.com

Flick switches are essential components found in various applications, from home electronics to industrial machinery. This comprehensive guide explores everything you need to know about flick switches, including their types, functionalities, applications, safety precautions, customization, maintenance, and how products like Carlingswitch differ from other brands. Whether you’re a homeowner looking for a decorative toggle switch or an engineer seeking industrial-grade flick switches, this article offers insights and tips to make the right choice. Dive in to explore the fascinating world of flick switches and discover the options that best suit your needs.

Table of Contents

1.Top 10 Most Asked Questions about Flick Switches

1. What are flick switches, and how do they work?

2. What are the different types of flick switches available?

3. How to install and replace a flick toggle switch?

4. What are the applications and uses of 2-way flick switches?

5. How do ON-OFF-ON toggle switches and industrial switches function?

6. Are flick switches safe and what precautions should be taken?

7. How to choose the right flick switch or toggle switch for specific needs?

8. Can flick switches be customized, and where to purchase them?

9. What are the common problems and troubleshooting techniques for flick switches?

10. How are Carlingswitch and other major brands positioned in the flick switch market?

2.What are Flick Switches, and How Do They Work?

Introduction to Flick Switches

Flick switches, also known as flick toggle switches or toggle switches, are mechanical devices used to control the flow of electricity in a circuit. They come in various forms and can be utilized in a wide range of applications.

Working Principle

Toggle switches work by flicking or toggling a lever or knob, connecting or disconnecting the circuit. When the switch is in the ON position, the circuit is complete, and current flows. In the OFF position, the circuit is open, and the flow of electricity stops.

Types of Flick Switches

Flick switches can be broadly categorized into 2-way flick switches, ON-OFF-ON toggle switches, and industrial switches. Their function varies based on design, application, and electrical ratings. Explore different types of toggle switches at [indicatorlight.com’s toggle switch category](https://www.indicatorlight.com/category/toggle-switch/).

Understanding the Mechanism

The core mechanism consists of a lever, contacts, and a spring. The user-operated lever moves the contacts to either complete or break the electrical circuit. These switches are widely used due to their simple design and ease of use.

Applications

Flick switches are commonly found in household appliances, automotive controls, industrial machinery, and various other applications. They are favored for their reliability and straightforward operation.

Safety Considerations

Like any electrical device, flick switches must be handled with care. Proper installation, usage, and maintenance are essential to ensure safety. It’s advisable to follow the manufacturer’s guidelines and consult professionals if needed.

Advantages and Disadvantages

Flick switches are known for their robustness and cost-effectiveness. However, they may not be suitable for some high-precision applications where other types of switches might be preferred.

Comparing with Other Switches

Compared to other types of switches, flick switches offer tactile feedback, are easily recognizable, and can be used in various environments. Their versatility makes them a popular choice among users.

Maintenance and Care

Regular inspection, cleaning, and proper handling can extend the life of flick switches. Avoiding excessive force and following the manufacturer’s instructions can prevent potential issues.

Conclusion of Section

Understanding flick switches, their types, working mechanism, and applications, enables users to make informed decisions. Whether it’s a simple 2-way flick switch or an industrial ON-OFF-ON toggle switch, knowing their functionality, benefits, and drawbacks can guide in choosing the right product.

3.What are the Different Types of Flick Switches Available?

Overview

Different types of flick switches cater to various needs and applications. From 2-way flick switches to Carlingswitch and industrial ON-OFF-ON toggle switches, the variety is vast. Explore further at [indicatorlight.com](https://www.indicatorlight.com/).

Toggle Switches

Toggle switches are basic flick switches with ON and OFF positions. Some variations offer more than two positions, such as the ON-OFF-ON toggle switches, providing more control options.

2 Way Flick Switches

2 Way Flick Switches allow control between two circuits or functions. They are widely used in applications like lighting, where they control two different light sources.

Carlingswitch

Carlingswitch is a popular brand that offers a variety of flick switches, including toggle and rocker switches. Known for quality and innovation, their products are used in various industries.

Industrial Switches

Industrial flick switches are designed to withstand harsh environments. They come in different specifications and can handle higher electrical loads compared to regular flick switches.

Multi-Position Switches

Some flick switches offer multiple positions, providing more flexibility and control. For instance, a three-position switch might include ON-OFF-ON configurations.

Specialty Switches

These flick switches are designed for specific applications, such as waterproof or dustproof environments. Special coatings or enclosures ensure that they perform under unique conditions.

Safety and Compliance

Different types of flick switches must meet specific safety standards and compliance requirements. Ensuring that a flick switch adheres to relevant regulations is vital.

Considerations for Selection

Choosing the right flick switch depends on factors like application, electrical ratings, size, and desired features. Understanding the types helps in making the right choice.

Conclusion of Section

Different types of flick switches serve diverse purposes, from basic toggle switches to specialized industrial switches. Knowing their categories and specific characteristics can assist in selecting the most appropriate flick switch for a particular application.

4.How to Install and Replace a Flick Toggle Switch?

Introduction to Installation

Installing or replacing a flick toggle switch is generally a straightforward process. It can be done by following proper guidelines and safety precautions, or you can visit [indicatorlight.com](https://www.indicatorlight.com/) for more details.

Preparing the Area

Ensure that the power is turned off before starting the installation. This includes disconnecting the device from the power source or turning off the circuit breaker.

Selecting the Right Switch

Choosing the correct flick switch, such as a 2-way flick switch or an ON-OFF-ON toggle switch, is essential. It must match the specifications of the existing switch or application requirements.

Removing the Old Switch

If replacing an old switch, carefully remove it from the housing or panel, paying attention to how the wires are connected. It helps in reconnecting the new switch accurately.

Connecting the New Switch

Connect the new flick toggle switch according to the wiring diagram or previous connections. Secure the wires, ensuring that they are firmly attached.

Testing the Installation

Before fully reassembling, it’s wise to test the flick switch to make sure it operates correctly. Turn the power back on and check the functionality.

Finalizing the Installation

Once tested successfully, securely mount the flick switch in its housing or panel. Ensure everything is tightened and positioned correctly.

Safety Precautions

Always follow safety guidelines, use proper tools, and wear appropriate protective equipment. If unsure, consult a professional electrician.

Troubleshooting

If the switch doesn’t work as expected, check the wiring connections, compatibility, and other factors that might be causing the issue.

Conclusion of Section

Installing or replacing a flick toggle switch can be a simple task when done with care and attention to detail. Whether it’s a basic toggle switch or a specialized industrial switch, following proper instructions and safety measures ensures a successful installation.

5.What are the Applications and Uses of 2-Way Flick Switches?

Introduction to 2-Way Flick Switches

2-Way Flick Switches, also known as double pole switches, allow control

between two circuits or functions. They are versatile and find applications in various fields.

Residential Applications

In homes, 2-way flick switches are commonly used for controlling lights from two different locations. It’s convenient for hallways, staircases, and large rooms.

Commercial Applications

In commercial spaces like offices, 2-way flick switches provide control over lighting, fans, and other electrical devices from multiple locations.

Automotive Uses

2-Way Flick Switches are also found in vehicles, where they control functions like lights or wipers, allowing drivers to switch between different modes.

Industrial Applications

In industrial environments, 2-way flick switches enable control over machinery and processes, providing flexibility in operations and control.

Marine and Aviation

Marine and aviation sectors also utilize 2-way flick switches to control various onboard systems, offering reliability and ease of use.

Specialized Applications

There are specialized 2-way flick switches designed for unique applications like medical equipment, military devices, and other specific needs.

Benefits of 2-Way Flick Switches

The main advantage of 2-way flick switches is the ability to control a device from two different locations, providing convenience and flexibility.

Selection Considerations

When choosing a 2-way flick switch, consider factors like electrical ratings, design, compatibility, and the specific application needs.

Conclusion of Section

2-Way Flick Switches are versatile devices that find applications across residential, commercial, automotive, and various other sectors. Their ability to control functions from two locations makes them a preferred choice in many scenarios.

6.How Do ON-OFF-ON Toggle Switches and Industrial Switches Function?

Understanding ON-OFF-ON Toggle Switches

ON-OFF-ON toggle switches are three-position switches that allow control between three different circuits or states. They offer more options compared to simple ON-OFF toggle switches.

Working of ON-OFF-ON Toggle Switches

These switches operate by moving the lever to one of the three positions. The ON positions activate two separate circuits, while the OFF position disconnects both. It allows for more complex control.

Applications

ON-OFF-ON toggle switches are utilized in various applications like machinery, lighting systems, and automotive controls, where multiple control options are required.

Industrial Switches

Industrial flick switches, including ON-OFF-ON variants, are designed for harsh environments. They can handle higher electrical loads and are often more robust.

Industrial Applications

Industrial switches are used in factories, plants, and other heavy-duty environments to control machinery, lighting, and processes.

Advantages of ON-OFF-ON Toggle Switches

The three-position control provided by ON-OFF-ON toggle switches offers flexibility and enhanced functionality in applications where multiple control options are needed.

Selecting the Right Industrial Switch

When choosing an industrial flick switch, consider factors like environmental conditions, electrical ratings, safety standards, and specific application requirements.

Safety and Compliance

Industrial switches must meet stringent safety and compliance standards. Proper selection, installation, and maintenance are crucial.

Conclusion of Section

ON-OFF-ON toggle switches and industrial switches offer unique functionalities and are designed for specific applications. Their working principles, advantages, and selection criteria must be understood to utilize them effectively.

7.Are Flick Switches Safe and What Precautions Should be Taken?

Introduction to Safety

Flick switches, like any electrical devices, must be used with proper care and precautions to ensure safety. Their design usually considers safety factors, but user awareness is equally important.

Safety Standards and Regulations

Flick switches must comply with relevant safety standards and regulations. It ensures that they are designed and manufactured with safety in mind.

Installation Precautions

Proper installation, following manufacturer’s guidelines, using the right tools, and taking necessary precautions like turning off the power, ensures a safe setup.

Usage Precautions

Avoid using flick switches with wet hands or in damp environments unless they are specifically designed for such conditions. Following usage instructions is vital.

Maintenance and Inspection

Regular inspection and maintenance of flick switches can detect and prevent potential safety issues. Keeping them clean and free from dust or debris ensures optimal performance.

Specialized Safety Switches

Some flick switches are designed for high-risk environments, such as explosive or corrosive settings. Using specialized switches in such scenarios is crucial.

Child Safety

In residential settings, child safety can be a concern. Using childproof flick switches or covers helps prevent accidental tampering.

Conclusion of Section

Safety with flick switches is a shared responsibility between manufacturers, installers, and users. Adhering to safety standards, taking proper precautions during installation, usage, and maintenance, and choosing the right switches for specific environments ensure a safe experience.

8.How to Choose the Right Flick Switch or Toggle Switch for Specific Needs?

Understanding the Needs

Choosing the right flick switch begins with understanding the specific needs and requirements of the application, including electrical ratings, design, and functionality.

Analyzing Different Types

There are various types of flick switches, such as 2-way flick switches, ON-OFF-ON toggle switches, and industrial switches. Knowing the differences aids in selection.

Consider the Environment

The environment where the switch will be used, such as indoors, outdoors, or industrial settings, influences the choice of the flick switch.

Compliance and Standards

Ensuring that the selected flick switch meets relevant compliance standards and regulations is vital for safety and performance.

Brand Considerations

Some brands like Carlingswitch are known for quality and reliability. Choosing a reputable brand may offer better assurance.

Customization Options

Some applications might require customized flick switches. Many manufacturers offer customization options to suit specific needs.

Consider the Aesthetics

In some scenarios, the appearance of the flick switch might be essential. There are design and color options to match various aesthetics.

Evaluate the Cost

Cost is an important factor, and understanding the balance between quality and budget helps in making an informed decision.

Expert Consultation

Consulting professionals or experts in the field can provide insights and recommendations tailored to the specific needs of the application.

Conclusion of Section

Choosing the right flick switch involves considering various factors like type, application needs, environment, compliance, brand, aesthetics, and cost. A thoughtful analysis and consultation with experts can guide in selecting the perfect flick switch for any scenario.

9.Can Flick Switches be Customized, and Where to Purchase Them?

Customization Options

Many manufacturers offer customization options for flick switches to meet specific requirements. This includes changes in design, electrical ratings, materials, and more.

Understanding Customization Needs

Defining the customization needs clearly is essential. Whether it’s a unique design or specific functionality, knowing the requirements helps in getting the right product.

Working with Manufacturers

Directly working with manufacturers can provide more flexibility in customization. They can tailor the flick switch to suit particular needs and applications.

Online Marketplaces

Online platforms and specialized websites like indicatorlight.com offer a wide range of flick switches, including customization options.

Physical Stores

Electrical and hardware stores also provide flick switches, though customization options might be limited compared to direct manufacturer collaboration.

Considerations for Customization

Customization might involve additional costs and lead time. Ensuring that the customized flick switch meets all standards and compliance is crucial.

Bulk Orders

For bulk or specialized requirements, working directly with manufacturers might offer advantages in terms of pricing and customization flexibility.

Conclusion of Section

Customizing flick switches

is a feasible option with many manufacturers and platforms offering tailored solutions. Understanding the specific needs, working closely with the manufacturers, or choosing the right platform ensures the best results.

10.What are the Various Flick Switch Accessories Available?

Introduction to Accessories

Flick switch accessories enhance functionality, aesthetics, or safety. They range from protective covers to decorative elements.

Protective Covers

Protective covers safeguard flick switches from dust, moisture, and accidental contact. They are particularly useful in industrial or outdoor settings.

Decorative Elements

Some flick switches come with decorative elements to match interior designs. They add aesthetic value to the overall appearance.

Mounting Options

Various mounting options, including brackets and plates, offer flexibility in installing flick switches according to specific needs and preferences.

Replacement Parts

Flick switches might require replacement parts like levers, springs, or contacts. Availability of these parts ensures longevity and optimal performance.

Specialized Accessories

Some specialized flick switches might need unique accessories, like key-operated levers, waterproof seals, or other specific elements related to their application.

Accessibility Add-Ons

Accessibility add-ons like larger levers or tactile indicators can make flick switches more user-friendly for people with disabilities.This design can give consumers more choice of products and better experience.

Conclusion of Section

Flick switch accessories offer a wide range of options to enhance functionality, aesthetics, safety, and accessibility. From protective covers to decorative elements and specialized add-ons, accessories can significantly enhance the usability of flick switches.

11.How to Properly Maintain and Care for Flick and Toggle Switches?

Understanding Maintenance Needs

Proper maintenance ensures the longevity and optimal performance of flick and toggle switches. Understanding the specific maintenance needs is the first step.

Regular Inspection

Regular inspection of flick switches helps in early detection of wear and tear, loose connections, or other potential issues.

Cleaning

Keeping flick switches clean from dust and debris is essential. Using appropriate cleaning methods and products prevents potential problems.

Replacement of Worn Parts

Replacing worn or damaged parts like levers or contacts at the right time prevents failures and maintains performance.

Professional Maintenance

In some cases, professional maintenance might be required, particularly for specialized or industrial flick switches.

Environmental Considerations

Considering the environment where the switch is used, such as humid, dusty, or corrosive, helps in defining the maintenance approach.

Safety During Maintenance

Always follow safety guidelines during maintenance, including turning off the power and using proper tools.

Maintenance Records

Keeping records of maintenance activities, including inspections, replacements, or repairs, provides insights into the condition of the flick switches.

Conclusion of Section

Proper maintenance of flick and toggle switches involves regular inspection, cleaning, replacement of worn parts, considering environmental factors, and following safety guidelines. It ensures their reliable performance and extends their lifespan.

12.How Do Carlingswitch Products Differ from Other Brands of Flick Switches?

Introduction to Carlingswitch

Carlingswitch is a reputed brand known for manufacturing various flick switches, including toggle switches, and other electrical products.

Quality and Reliability

Carlingswitch products are often associated with quality and reliability. They use superior materials and adhere to strict manufacturing standards.

Wide Product Range

Carlingswitch offers a wide range of flick switches catering to different applications, from residential to industrial. Their portfolio provides extensive options.

Customization Opportunities

Carlingswitch offers customization options to meet specific needs, making them a preferred choice for specialized applications.

Innovation and Technology

Carlingswitch invests in innovation and technology, leading to advanced and efficient flick switch designs.

Global Presence

With a global presence, Carlingswitch products are accessible in various markets, ensuring availability and support.

Pricing Considerations

Carlingswitch products might be priced differently compared to other brands, reflecting their quality, support, and customization options.

Conclusion of Section

Carlingswitch stands out from other brands in terms of quality, product range, customization, innovation, global presence, and pricing considerations. Their reputation and offerings make them a notable choice in the flick switch market.

Conclusion

Flick switches are versatile devices used across various sectors for different purposes. Understanding their types, functionalities, applications, safety precautions, customization possibilities, maintenance needs, and choices available in the market, including notable brands like Carlingswitch, helps in making informed decisions. Whether it’s a simple toggle switch for home use or an industrial flick switch for a manufacturing plant, careful consideration of various aspects ensures optimal selection and utilization. The market offers a plethora of options, and platforms like indicatorlight.com provide a convenient place to explore and purchase the right flick switches for any need.