Choosing the right material for a push button switch is a strategic decision for any project. It’s more than just a matter of preference; the choice directly impacts a product’s performance, safety, and long-term value. For purchasing managers and technical professionals in the US and Europe, understanding the pros and cons of metal and plastic is crucial. This guide provides a clear breakdown to help you make an informed decision that meets your technical and business goals.

Metal vs. Plastic Push Button Switches: Your Ultimate Procurement Guide

The Advantages of Metal Push Button Switches

A metal push button switch is built for strength and durability. They are a top choice for applications where toughness is a must.

Unmatched Durability and Strength

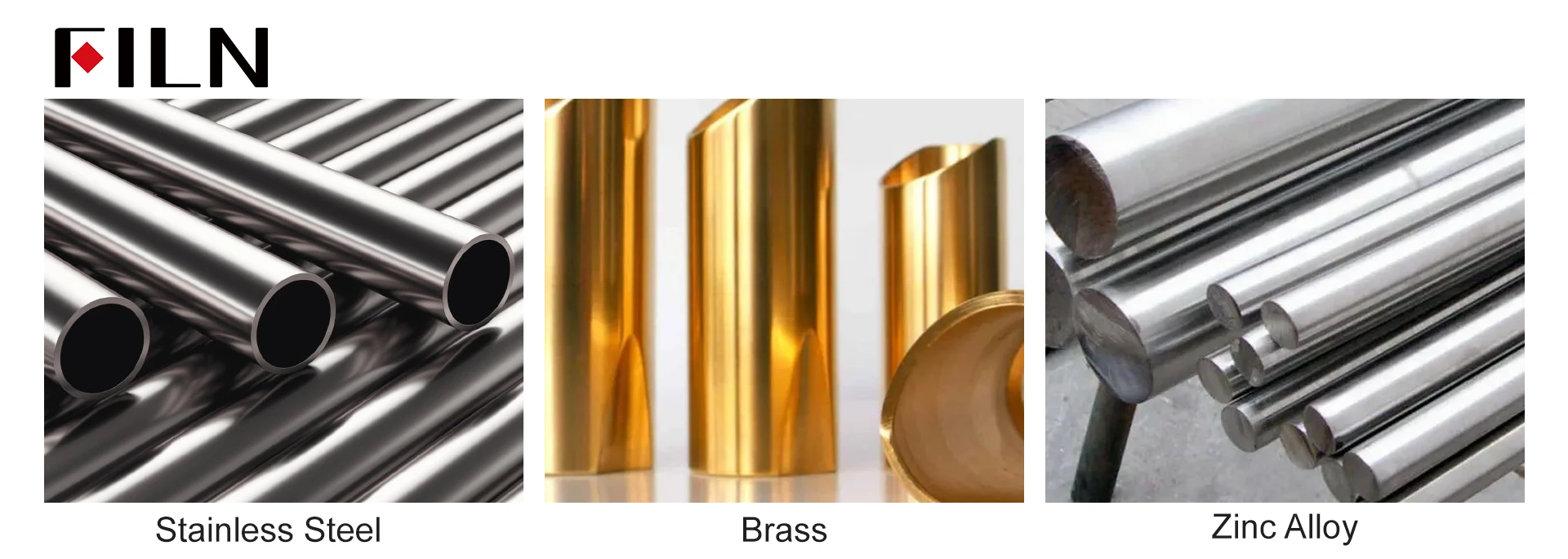

Metal push button switches are known for their exceptional toughness. They are resistant to heavy use and physical damage. This makes a metal push button switch ideal for high-stress environments. Common materials for a metal push button switch include stainless steel, brass, and zinc alloy.

- Stainless Steel: This material is perfect for harsh environments. It offers superior strength and resists corrosion. Stainless steel push button switches are a reliable choice for marine applications and public spaces.

- Brass: Brass is a popular choice for electrical switches due to its durability and excellent electrical conductivity. It provides a luxurious look at a lower cost, making it suitable for indoor use.

- Zinc Alloy: Zinc alloy provides a good balance between strength and cost. Its surface can be electroplated in many colors to match your design needs.

To measure a switch’s resistance to impact, the IK rating is used. It ranges from IK00 (no protection) to IK10, the highest level of protection. An IK10-rated metal push button switch can withstand an impact of 20 joules, which is like a 5 kg object dropped from 400 mm. This high level of protection is essential for vandal-resistant push button switch applications like ATMs, elevators, and public terminals.

Superior Environmental Resilience

Metal enclosures are great at handling tough conditions. They manage heat well, which protects sensitive internal components in high-temperature settings. A metal push button switch also provides superior protection against electromagnetic interference (EMI) and radio frequency interference (RFI). This is vital for sensitive electronics that need to be shielded from outside signals.

A Premium Look and Feel

A metal push button switch offers a sleek, professional, and modern appearance. They are often used in high-end appliances, car dashboards, and control panels. Their solid feel gives users confidence that the button worked properly. The look of a metal push button switch can directly enhance a product’s brand image.

The Advantages of Plastic Push Button Switches

A plastic push button switch offers a flexible and cost-effective alternative. They are great for a wide variety of applications.

Cost-Effectiveness and Lightweight Design

One of the biggest advantages of a plastic push button switch is its low initial cost. The materials and manufacturing processes for a plastic push button switch are generally more affordable than those for metal. This makes them a great choice for budget-conscious projects or products. Plastic push button switches are also much lighter than metal ones, which is important for portable devices.

Versatility and Electrical Safety

A plastic push button switch is made from materials like polycarbonate, nylon, and ABS. The injection molding process allows manufacturers to create a plastic push button switch in many different shapes, sizes, and colors. This gives designers a lot of freedom.

Plastic is a natural electrical insulator. This means a plastic push button switch helps prevent electrical leakage, adding a layer of safety. Many plastic switches are also made with flame-retardant materials to meet safety standards.

Resistance to Corrosion

Unlike some metals, plastic does not rust. This makes a plastic push button switch a perfect choice for wet, humid, or coastal environments. In these settings, a plastic switch will perform reliably without the need for special coatings.

Strategic Selection: Metal vs. Plastic

Choosing between a metal push button switch and a plastic push button switch is about matching the material to the application.

When to Choose a Metal Push Button Switch

- Industrial Machinery: In factories and workshops, a metal push button switch is used to start, stop, or reset equipment. They can withstand dusty, oily, or hot conditions without failing.

- Public and Vandal-Prone Areas: For ATMs, elevator panels, and public terminals, a metal push button switch with a high IK rating is essential. These switches are built to resist abuse and frequent use, ensuring long-term reliability.

- Automotive and Medical Devices: A metal push button switch is often used in car dashboards and medical equipment due to its reliability and durability in critical, high-use applications.

Key Standards and Future Trends

For the US and European markets, compliance with standards is a must.

Essential Certifications: UL and CE

- UL Certification: UL (Underwriters Laboratories) is a key safety certification in the US. A UL-certified push button switch has been tested to meet strict safety standards.

- CE Marking: The CE mark shows that a product meets high safety, health, and environmental standards within the European Economic Area (EEA). Both UL and CE certifications are crucial for market entry and building customer trust.

Conclusion

The choice between a metal push button switch and a plastic push button switch is a critical one for any project. There is no single “best” option. A metal push button switch offers superior durability and a premium feel, making it the ideal choice for high-stress industrial and public applications where long-term reliability and vandal resistance are key. In contrast, a plastic push button switch provides a cost-effective, lightweight, and versatile solution, perfect for consumer electronics and projects where design flexibility and electrical insulation are priorities. By considering the specific needs of your application, from environmental factors to long-term costs and certifications, you can make an informed decision that ensures the success of your product.