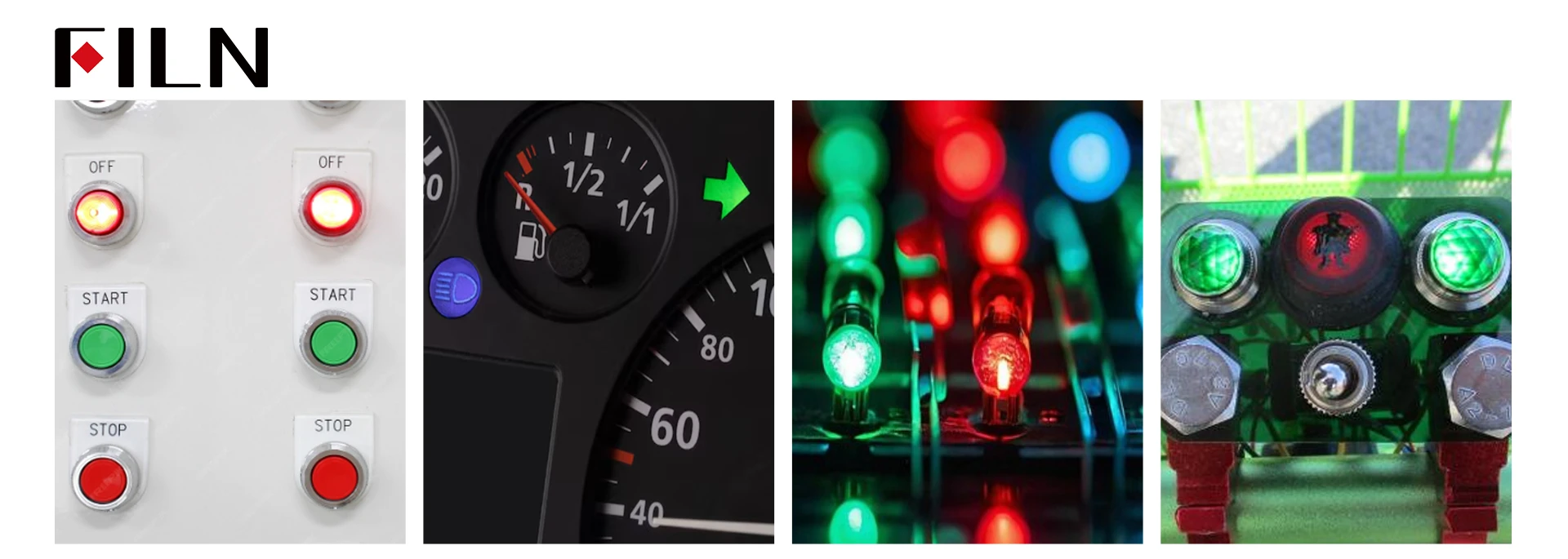

In the intricate world of electronics and industrial design, every component plays a crucial role. Among the smallest but most significant of these are LED indicator lights. They serve as the visual language of a device, providing instant, intuitive feedback on its power, status, and health. For engineers, product designers, and procurement specialists, selecting the right indicator light is not just a matter of color or brightness; it’s a critical decision that impacts product reliability, safety, and user experience.

This comprehensive guide is crafted to serve as your ultimate resource for everything related to LED indicator lights. We’ll delve into the fundamentals, explore common types and applications, provide a detailed selection checklist, and most importantly, guide you through the process of sourcing the perfect solution from a trusted, professional manufacturer.