The Ultimate Guide to Indicator Lights: Types, Applications, and Future Innovations for Enhanced Visibility and Control

The Ubiquitous Role of Indicator Lights in Modern Systems

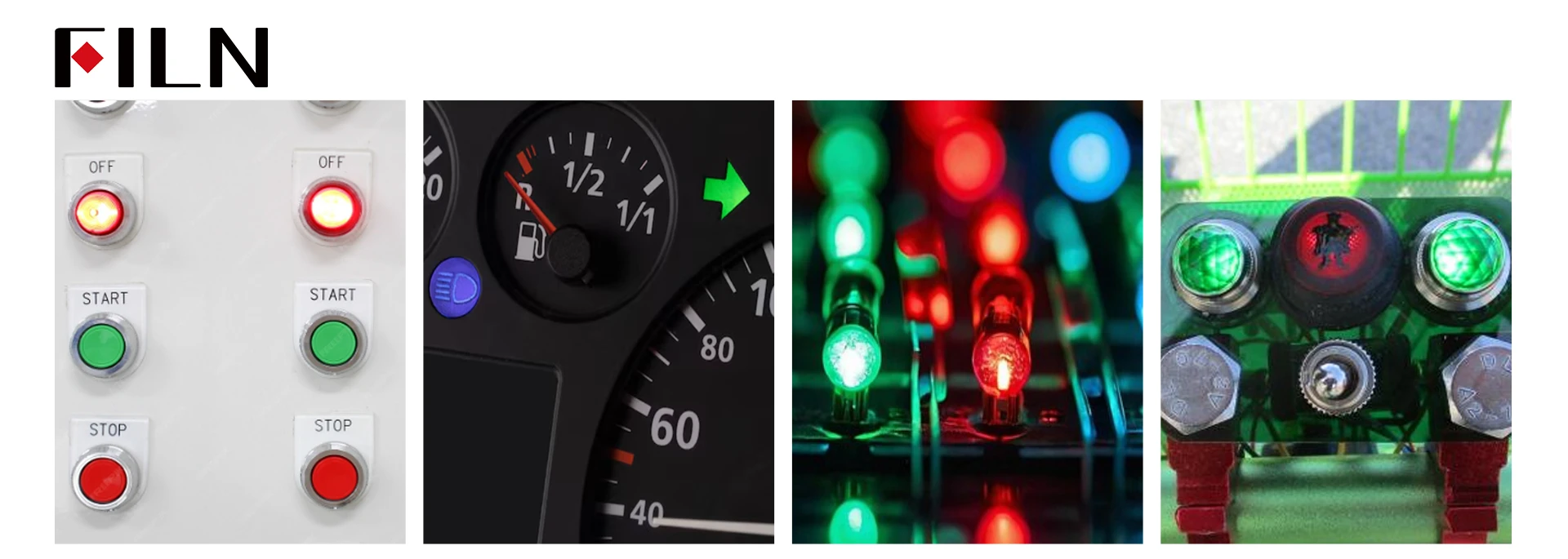

Indicator lights are indispensable components within electronic and electrical systems, serving the crucial function of providing visual signals that effectively communicate the operational status, mode, or specific conditions of a device, system, or process. This visual feedback is paramount for enhancing safety, optimizing operational efficiency, and improving user interface design across a myriad of environments. They are also commonly known as signal lights, warning lights, or simply indicators.

Understanding the Importance of Indicator Lights for Professionals and Consumers

For industry professionals, including engineers, manufacturers, and product designers, a deep understanding of indicator lights is essential. This encompasses informed selection, seamless integration into complex systems, adherence to safety standards, and the strategic adoption of emerging technologies.

For the average consumer, interpreting common indicator light signals, especially those found on automotive dashboards or household electronics, is vital for personal safety, effective troubleshooting, and maximizing the efficient use of their devices.

II. Understanding Indicator Lights: From Basic Function to Advanced Features

What is an Indicator Light? (Definition and Core Purpose)

An indicator light is a concise visual communication tool used to denote the operational status, condition, or state of a device, system, or electronic component. Their fundamental purpose is to provide immediate visual feedback, thereby enhancing user comprehension and safety by clearly indicating power status, operational modes, or potential issues. Beyond simple status indication, they are also designed to warn of malfunctions or hazards, guide user actions through operational sequences, and confirm the successful completion of system processes.

Key Characteristics of Indicator Lights: Efficiency, Durability, and Visibility

Modern indicator lights, particularly those employing LED technology, are highly valued for their exceptional energy efficiency, consuming significantly less power compared to traditional alternatives, thus contributing to substantial energy savings.

A notable characteristic of contemporary indicator lights is their extended operational lifespan, often ranging from 50,000 to 100,000 hours. This longevity substantially reduces replacement frequency and associated maintenance costs.

High brightness and clear illumination are critical features, ensuring that visual signals from an indicator light are distinctly discernible even in challenging ambient light conditions or low-visibility environments.

Durability is a paramount consideration, with options such as robust metal housings and IP67 waterproof ratings providing superior resistance to moisture, dust, vibration, and extreme temperatures.

Common Indicator Light Colors and Their Meanings

| Color | MeaningCommon | Applications/Examples |

| Red | Critical Issue / Danger / Stop | Engine oil pressure warning, brake system malfunction, emergency stop |

| Green | Normal Operation / Safe Condition | Turn signals, device powered on, machine normal operation |

| Yellow/Amber | Warning / Caution / Intermediate State | Check engine light, tire pressure low, overheating, pressure changes |

| Blue | Informational / Special Condition / Maintenance | High beams, Bluetooth connection, maintenance in progress |

| White | General Indication / Neutral Status / Production Mode Change | General status, standby mode, production mode changes |

| Orange | Warning / Cautionary Signal | Engine temperature warning, low fuel |

The standardized color coding of indicator lights is a critical aspect of their design, establishing a universal visual language essential for rapid and unambiguous communication, thereby significantly enhancing safety and operational efficiency across all application sectors. Multiple sources confirm the consistent, standardized meanings of indicator light colors. This represents a crucial design principle and a universal visual language. This standardization ensures immediate and intuitive communication, which is vital for safety in high-stakes environments like automotive and industrial machinery, while also contributing to maintaining operational efficiency. Without this consistent color coding, misinterpretation could lead to serious accidents, costly downtime, or user frustration.

III. Delving into Indicator Light Types and Their Unique Advantages

LED Indicator Lights: The Modern Standard

Light Emitting Diode (LED) indicator lights have become the predominant choice in modern applications due to their exceptional energy efficiency, extended lifespan, and intense, bright illumination. They offer high visibility and are customizable in a wide array of colors (red, green, blue, yellow, white), including sophisticated bi-color and tri-color configurations to convey more nuanced information.

LEDs can be seamlessly integrated into both metal and plastic housings, providing significant design flexibility and enhanced durability where required for an indicator light.

Traditional Choices: Incandescent and Neon Indicator Lights

Incandescent Indicator Lights: These indicator lights are characterized by their cost-effectiveness and ease of replacement. They are primarily used in legacy systems or basic signaling applications where a warm, traditional glow is acceptable. However, due to the widespread advancements and advantages of LED technology, their use has become less prevalent.

Neon Indicator Lights: Known for their distinctive visibility and relatively low power consumption, neon indicator lights are often employed in high-voltage applications or for specific decorative lighting purposes that demand their unique aesthetic.

Metal LED Indicator Lights: Engineered for superior durability and resilience, metal LED indicator lights often feature an IP67 waterproof rating, making them ideal for demanding and challenging environments. They are inherently resistant to shock, corrosion, and vibration, ensuring reliable, safe, and long-lasting performance in harsh conditions. For example, FILN’s 8mm metal indicator light is particularly noted for its robustness and suitability in industrial, automotive, and outdoor applications.

Plastic LED Indicator Lights: These indicator lights offer a cost-effective and aesthetically versatile solution. They are available in various sizes, shapes (such as round, rectangle, and square), and a broad spectrum of LED colors, providing flexible options for a wide range of applications where extreme durability is not a primary requirement.

Key Characteristics and Applications of Different Indicator Light Types

| Type | Key Characteristics | Common Applications |

| LED Indicator Light | Energy-efficient, long lifespan, bright, color-customizable | Consumer electronics, industrial control panels, automotive dashboards, medical equipment |

| Incandescent Indicator Light | Cost-effective, warm glow, easy to replace | Legacy systems, basic signaling |

| Neon Indicator Light | High visibility, low power consumption, high-voltage suitability | High-voltage circuits, decorative lighting |

| Metal LED Indicator Light | Extremely durable, IP67 waterproof, shock-resistant | Harsh industrial environments, heavy machinery, automotive exteriors |

| Plastic LED Indicator Light | Cost-effective, wide range of shapes/colors | General consumer appliances, indoor control panels, DIY projects |

Research indicates that LED technology has emerged as the superior and increasingly dominant standard due to its inherent advantages in energy efficiency, longevity, and brightness. This is a fundamental technological evolution driven by market demand for sustainable and reliable solutions. Consequently, the choice between metal and plastic housings for LED indicator lights becomes a strategic decision for manufacturers and buyers, depending on the specific environmental demands of the application (e.g., harsh industrial conditions requiring metal, while cost-sensitive consumer products lean towards plastic) and aesthetic considerations. This implies that successful manufacturers like FILN must not only prioritize advanced LED technology but also offer diverse material options to cater to a broad spectrum of market needs.

IV. Industry Applications: Where Indicator Lights Shine Brightest

Automotive Sector: Dashboard and Other Critical Indicator Signals

Indicator lights play a pivotal role in the automotive industry, providing essential visual cues for turn signals, hazard warnings, and comprehensive vehicle status information.

Industrial and Manufacturing: Enhancing Safety and Operational Efficiency with Indicator Lights

In industrial and manufacturing environments, indicator lights (often deployed as stack lights or signal towers) are essential for control panels. They visually display machine status, provide immediate fault alerts, and offer continuous operational feedback.

Their presence significantly enhances safety by providing immediate visual feedback, which is particularly crucial in noisy or busy industrial settings where auditory signals might be overlooked.

Industrial applications of indicator lights often use standardized color codes, including: green for normal operation, yellow/amber for warning or caution states, red for critical faults or emergencies, blue for maintenance or service in progress, and white for specific status changes or custom meanings.

Consumer Electronics and Smart Home Devices: Intuitive User Feedback from Indicator Lights

In consumer electronics, indicator lights communicate essential information such as power on/off status, charging progress, Wi-Fi connectivity, and other operational states.

In smart home systems, they intuitively display the status of smart devices or security systems, indicating armed/disarmed modes or network connectivity.

A CNET review highlights a significant but often overlooked consumer pain point: overly bright LED indicator lights on devices that can disrupt sleep or comfort. This has led to the development of “light dimming stickers” solutions, indicating a clear market need for more user-friendly, less intrusive indicator light designs in consumer products.

Specialized Applications of Indicator Lights: Medical Devices, Telecommunications, and More

In medical devices, indicator lights provide critical visual feedback, including device operation, battery status, and serve as immediate alarm signals for critical conditions requiring urgent attention.

Fiber optic indicator lights are specifically utilized in medical equipment and telecommunications due to their inherent flexible design and minimal heat generation, which is crucial for sensitive applications.

Beyond these, indicator lights are integrated into various household appliances (e.g., washing machines, ovens), commercial establishments (e.g., retail stores, offices, elevators), and even niche applications like guitar switches, where FILN demonstrates expertise with 3PDT switches.

The evolution of indicator lights from simple “on/off” signals to sophisticated communication tools is evident across all industries. In automotive, they are deeply integrated into complex diagnostic and safety systems. In industrial settings, they are integral to real-time safety protocols and operational efficiency. Crucially, the CNET snippet reveals that in consumer electronics, poorly designed indicator lights can become a nuisance, leading to a market for solutions to dim or cover them. This marks a critical shift from purely functional design to user experience-driven design. Indicator lights are no longer just passive signals but are becoming active components of the user’s environment, requiring nuanced consideration of factors like brightness control, ambient light conditions, and context-aware signaling to ensure they enhance rather than detract from the user experience. This also ties into broader concepts like “responsible innovation” and “new human-machine collaboration models”.

V. Choosing, Installing, and Maintaining Your Indicator Lights

Considerations for Optimal Indicator Light Selection

Voltage and Current Ratings: It is crucial to ensure that the voltage and current requirements of the chosen indicator light are fully compatible with the intended power supply to prevent damage and ensure proper function.

Brightness and Visibility: The brightness of the indicator light is a citical factor, as it must be easily discernible within its operational environment, whether in bright daylight or low-light conditions.

Durability and Environmental Conditions: Selection must account for the operating environment. This includes choosing indicator lights with appropriate ingress protection (IP ratings, e.g., IP67 for waterproof applications), robust material resilience (e.g., metal for harsh conditions), and resistance to shock, vibration, and extreme temperatures.

Mounting Style: Various mounting options are available, including flush mount, panel mount, or surface mount. The choice depends on the device’s size, available space, and aesthetic considerations. For example, FILN produces over 500 types of panel indicator lights, offering a wide range of choices.

Color Coding: Adherence to industry-standard color coding is essential for consistent and unambiguous communication. This includes using red for warnings, green for normal operation, yellow for caution, blue for specific conditions, and white for general indication.

Customization Options: For unique applications or specific design requirements, consider manufacturers like FILN who offer extensive customization options in terms of size, color, and overall design of their indicator lights.

Installation Best Practices: Step-by-Step Wiring for LED Indicator Lights

Determine Polarity: LEDs are polarity-sensitive devices. It is crucial to correctly identify the positive (anode) and negative (cathode) terminals of the LED indicator light before wiring.

Connect Wires: Once polarity is determined, connect the positive wire of the LED indicator light to the positive wire of the power supply, and similarly, connect the negative wire of the LED indicator light to the negative wire of the power supply.

Secure Mounting: Ensure the indicator light is securely mounted to prevent loosening due to vibration or impact, which also guarantees consistent visibility. For panel-mount indicator lights, using appropriate tools like a penetrator wrench ensures secure tightening.

Proper Wiring: Always strictly follow the manufacturer’s guidelines and wiring diagrams to ensure safe and correct electrical connections, avoiding malfunctions or hazards.

Testing: After installation, apply power to verify that the LED indicator light illuminates correctly, confirming accurate wiring and proper device function.

Common Troubleshooting and Ensuring Indicator Light Longevity

Regular Inspections: Implement a routine schedule for inspecting indicator lights for signs of wear, physical damage, or intermittent malfunction.

Cleanliness: Maintain cleanliness by regularly cleaning the surface of the indicator light to prevent dirt, dust, or obstructions from impairing visibility.

Timely Replacement: Establish protocols for timely replacement of bulbs or LEDs as they approach their end-of-life to ensure continuous and reliable signaling.

Addressing Annoying Brightness: For consumer-facing applications, the existence of solutions like light dimming stickers highlights the need for manufacturers to integrate dimmable features or design less intrusive indicator lights to enhance user comfort. Manufacturers who proactively offer dimmable features or design indicator lights that consider ambient light conditions can gain a significant competitive advantage. This directly links to broader industry trends like “responsible innovation” and “new human-machine collaboration models” , where technology should enhance human experience rather than create new nuisances.

Automotive Troubleshooting: Familiarize yourself with the meanings of various dashboard indicator lights and understand when professional mechanic assistance is required (e.g., persistent red warning lights, multiple indicator lights illuminated, or accompanying unusual vehicle symptoms).

VI. The Future of Illumination: Emerging Trends in Indicator Light Technology

Smart Integration and IoT Connectivity: Real-time Data and Remote Control for Indicator Lights

The indicator light market is experiencing robust growth, significantly driven by advancements in smart integration and IoT connectivity.

A major paradigm shift is occurring, where the functionality of indicator lights is evolving from simple on/off capabilities to networked, sensor-driven smart lighting systems that can respond to the environment in real-time.

IoT integration empowers features such as remote monitoring and control, real-time data analytics, and adaptive behavior through machine learning algorithms.

Practical applications include smart buildings, retail environments, and advanced smart home systems, where indicator lights can be controlled remotely via smartphone apps, react to motion or ambient light conditions, and even mimic occupancy patterns for enhanced security.

This trend is closely aligned with the broader rise of autonomous systems and evolving human-machine collaboration models, where technology is designed to be more intuitive and responsive to human intent and behavior.

Advancements in Energy Efficiency and Sustainable Indicator Light Design

While LEDs already offer significant energy savings, continuous innovation in advanced chip designs is further boosting their efficiency, leading to extended lifespans, some reaching 50,000 hours or more.

The increasing industry focus on sustainability is evident in a notable shift towards using recyclable materials and adopting eco-friendly production processes for indicator lights to align with global environmental objectives.

VII. Partnering with Precision: Why FILN is Your Go-To Indicator Light Manufacturer

Commitment to Quality Indicator Lights: Certifications and Rigorous Testing

Established in 1998, FILN has solidified its position as one of the leading global manufacturers of indicator lights and related components.

Their extensive product portfolio, including LED indicator lights, metal indicator lights, panel indicator lights, push button switches, and rocker switches, adheres to stringent international quality standards, evidenced by certifications such as UL, CE, ROSH, VDE, and ISO9001.

FILN operates a dedicated switch laboratory that has successfully passed rigorous UL and VDE standards. This facility is equipped with advanced testing instruments, including waterproof test benches, aging test benches, high voltage measurement instruments, and specialized switch life and current testers, all underscoring their unwavering commitment to product quality and reliability.

Innovation and Customization Capabilities for Indicator Lights

FILN positions itself as an innovative industrial and trading company, seamlessly integrating Research & Development (R&D) with production and sales capabilities.

They boast a seasoned R&D team with two decades of experience, specializing in the continuous development of various switches and LED indicator lights. This team demonstrates agility, capable of completing samples within 25 days to precisely meet personalized customer requirements.

FILN offers comprehensive support for customized production, catering to a wide array of styles and specifications, including custom indicator lights and panel indicator lights.

Their manufacturing prowess is evident in their ability to produce over 500 different kinds and types of panel indicator lights, with the flexibility to accommodate small-scale production orders.

Expert Customer Support and Global Reach for Indicator Lights

FILN provides a 24-hour LED indicator light switch knowledge solution service, demonstrating its commitment to continuous customer support.

Their experienced service team, with over 18 years of overseas sales experience and 6 years of international exhibition participation, enables them to offer comprehensive solutions and customized services while navigating complex international trade regulations.

The company prides itself on rapid response to inquiries and quotes, providing expert guidance and support for projects of all sizes, including small-batch production.

FILN’s significant global footprint is highlighted by 73% of its total turnover originating from export markets.

Positive feedback for their switch products on platforms like eBay consistently emphasizes their reliable performance, durable construction, and ease of installation, reflecting overall customer satisfaction with their manufacturing quality.

FILN Indicator Light Product Specifications (Example: 8 mm Metal Indicator Light)

| Parameter | Value | Key Application Scenarios |

| Voltage | 3V–250V | Industrial settings (control panels, error conditions), consumer electronics (audio systems, gaming consoles, appliances), automotive (turn signals, hazard lights, seatbelt reminders), home automation (smart devices, security systems), medical equipment (device operation, alarms) |

| Rated Current | 20mA | |

| Rated Power | 0.2W | |

| Insulation and Voltage Resistance | 1800V / 5s | |

| Working Life | 100,000h | |

| Cold-Resistant | -40℃ | |

| Heat-Resistant | 80℃ | |

| LED Color | R / G / B / Y / W |

FILN’s most compelling competitive advantages lie in its comprehensive portfolio of international quality certifications, state-of-the-art certified R&D and testing facilities, and proven ability to deliver customizable, high-performance indicator light solutions, which collectively build trust and authority in the market.

VIII. Conclusion: Guiding Decisions with Clear Indicator Signals

Indicator lights play an indispensable and evolving role across diverse applications, proving crucial for enhancing safety, improving operational efficiency, and optimizing user experience within increasingly complex technological landscapes.

Significant advancements and emerging trends in areas such as LED technology, smart integration, and next-generation display solutions are profoundly transforming the indicator light industry. These innovations are shifting indicator lights from simple signaling devices to intelligent, interconnected components that not only provide visual communication but also serve as active data points within sophisticated smart systems, demanding a holistic approach to innovation that encompasses hardware, software, and connectivity.

Therefore, informed selection, meticulous installation, and proactive maintenance are essential for ensuring optimal performance, extended longevity, and overall user satisfaction in any indicator light application. This includes adopting a user-centric design approach that considers the long-term impact of indicator lights on the user’s environment and comfort, offering features like brightness control to enhance overall satisfaction and prevent user fatigue.

In summary, FILN stands as a reliable partner committed to delivering high-quality, customizable, and future-ready indicator light solutions, with its dedication to quality, continuous innovation, and comprehensive customer support making it a strategic choice within the industry.