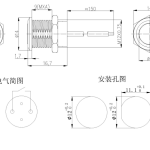

Product Drawings:

Push Pull Button Switch

- Name:Push Pull Button Switch

- Model:GQB19

- Head Type:Falt Head

- Size:16mm

- Switching Functions:Momentary

- Contact Configuration:1NO

- Rated Voltage: 3mA~15A

- Voltage Options:12V-250V /DC

- Material:ABS plastic, Plastic

- Download Certification:CE, CCC, ROSH, UL

- Email:inquiry@cnylin.com.cn

Product Parameters:

| Product Name | Push Pull Button Switch |

| Operation Type | Latching |

| Light Voltage | DC 12V |

| Contact Type | 1NO |

| Material | Plastic |

| Mounting Hole Dia. | 16mm |

| Included Components | Micro Switch (optional, not included) |

Related products:

Table of Contents

Complete Guide to Push Pull Button Switch

Whether you’re tinkering with a DIY project or trying to understand industrial machinery, push pull button switches are a key component you’re likely to encounter. This comprehensive guide delves into everything you need to know about these versatile switches. From common problems and how to wire them, to their compatibility with 12-volt systems and even their differences from auto toggle switches, we’ve got you covered. Read on to get a full grasp of push pull button switches and elevate your understanding of this essential hardware.

What is a Push Pull Button Switch?

A Push Pull Button Switch is a type of mechanism that controls the flow of electricity in a circuit. It offers two states, ‘pushed’ and ‘pulled,’ which often correspond to the on and off positions. Push Pull Button Switches are versatile and can be used in various applications like machinery, vehicles, and household items. They come in different shapes and sizes and can be equipped with features like LED indicators for added functionality. If you want to know more about what a push-button switch is, you can check out this article.

Point of View 1: Mechanical Functionality

The key aspect of push pull button switches is their mechanical functionality. Unlike a simple toggle or rocker switch, a push-pull mechanism involves a unique design that lets you both push and pull the switch to operate it. This design usually incorporates a spring-loaded mechanism that pops back when released, resetting the switch.

Point of View 2: Applications

Push Pull Button Switches have a variety of applications. They are commonly found in car dashboards, heavy machinery, or household appliances. Their robustness and easy-to-use nature make them popular choices for many situations. These switches are particularly useful in environments where space is at a premium, as their design is often more compact than other types of switches.

Point of View 3: Electrical Characteristics

From an electrical point of view, push-pull switches can manage different voltage and current capacities. They can be low-voltage switches for small appliances or heavy-duty switches capable of handling more substantial loads. Before choosing a switch, it’s important to understand its electrical capabilities to ensure it matches your requirements.

How Does a Push Pull Button Switch Work?

Understanding how a Push Pull Button Switch operates is crucial for selecting the right one for your needs. A simple push-pull switch will have a knob that you can either push in or pull out. Each of these states will usually correspond to a different circuit connection being made or broken. For more in-depth information on how a push-button switch works, you can visit this link.

Point of View 1: Mechanical Operation

Mechanically, a push-pull switch typically employs a spring-loaded mechanism. This allows it to return to its original position when released, providing tactile feedback to the user. The internal mechanism toggles between two or more states as the knob is pushed and pulled.

Point of View 2: Electrical Operation

Electrically, when you push or pull the button, different electrical contacts within the switch are connected or disconnected. This changes the flow of electricity and allows the switch to perform different functions, such as turning a device on or off or changing settings.

Point of View 3: Multi-Functional Uses

In more advanced models, a single push-pull switch may perform multiple functions. For example, pushing might activate one circuit, and pulling might activate another. This makes them extremely versatile, allowing users to control multiple functions from a single interface.

How to Install a Push Pull Switch?

If you’re considering installing a Push Pull Button Switch, it’s vital to follow correct procedures to ensure safety and proper functioning. To understand how to wire a push-button switch, you can refer to this guide.

Point of View 1: Safety Precautions

Before installing, always disconnect the electrical supply to the circuit where you’ll install the switch. Use safety equipment like gloves and goggles. Make sure you’re working in a well-lit environment.

Point of View 2: Wiring Diagram

Follow the wiring diagram provided with the switch or consult an electrician. This will generally show you where to connect each wire. Understanding the push-pull switch wiring diagram is essential for a successful installation.

Point of View 3: Tools and Materials

You’ll need various tools, including screwdrivers, wire strippers, and possibly a multimeter to test connections. Having the right tools can make the installation process much smoother.

What are the Types of Push Pull Button Switches?

Push Pull Button Switches can be categorized in multiple ways—by shape, size, functionality, or the kind of application they’re intended for. To explore different types of push-button switches, check out this page.

Point of View 1: By Voltage

One way to categorize these switches is by the voltage they can handle. For instance, a push-pull switch 12v would be suitable for low-voltage applications like car dashboards or small appliances.

Point of View 2: By Duty

Another way to categorize these switches is by their duty cycle. Heavy duty push-pull switches are designed to handle larger electrical loads and are often used in industrial settings.

Point of View 3: By Additional Features

Some switches come with added features like LED indicators or customizable labels. These additional features can enhance the user experience and provide more information about the switch’s state.

How Do I Choose the Right Push Pull Button Switch?

Choosing the right push-pull button switch can be a daunting task given the multitude of options available. Knowing what to look for can make the process easier.

Point of View 1: Determine the Application

First, identify the application for which you need the switch. Different applications will require different types of switches. For example, if you’re working on a 12v project, you might opt for a push-pull switch 12v.

Point of View 2: Consider the Electrical Specifications

It’s crucial to consider the electrical specifications like voltage and current ratings. Make sure the switch you choose can handle the electrical load you’ll be putting on it.

Point of View 3: Examine Additional Features

Lastly, consider any additional features you may want, such as an LED indicator or a specific type of connection. Make sure the switch fits your specific needs and requirements.

How to Wire a Push Pull Button Switch with LED?

Wiring a push-pull button switch with an LED requires some extra steps compared to a regular push-pull switch. To understand how to wire a push-button switch with an LED, you can refer to this guide.

Point of View 1: LED Connection

When wiring a switch with an LED, you’ll have an additional set of terminals for the LED connections. Make sure to connect these correctly to ensure that the LED lights up when the switch is activated.

Point of View 2: Power Requirements

LEDs require a certain voltage and current to operate. Make sure the electrical supply you are using can meet these requirements. You may need a resistor to limit current to the LED.

Point of View 3: Aesthetic Considerations

The LED can also serve as a visual indicator. Consider what color LED you want, as different colors can convey different meanings or match with the overall aesthetic of your project.

How to Maintain a Push Pull Button Switch?

Maintaining your Push Pull Button Switch is essential for ensuring its longevity and reliability.

Point of View

1: Regular Inspection

Regularly inspect the switch for any signs of wear and tear. This includes checking for any visible damage, loose wires, or erratic behavior during operation.

Point of View 2: Cleaning

Over time, dust and debris can accumulate inside the switch, affecting its performance. Make sure to clean it periodically to ensure optimal functioning. However, make sure to disconnect the power supply before cleaning.

Point of View 3: Replacement

Even the best switches have a finite lifespan. Be prepared to replace your switch when it shows signs of failure. It’s generally better to replace a failing switch sooner rather than later to avoid any potential safety hazards.

What are the Symbols Used for Push Pull Button Switches?

Symbols are commonly used to indicate the functionality of push pull button switches. These symbols can be especially helpful in complex circuits. To know more about push pull button symbols, you can refer to this page.

Point of View 1: Standard Symbols

There are standard symbols used to denote the functionality of push-pull switches. These are usually printed on the switch itself or indicated in its documentation. Knowing these symbols can help you understand the switch’s function at a glance.

Point of View 2: Industry-Specific Symbols

Some industries have specific symbols that they use for push-pull switches. For example, automotive or aerospace industries may have their unique set of symbols for these switches.

Point of View 3: Custom Symbols

In some cases, manufacturers or users may choose to use custom symbols for specific applications. These are typically found in specialized or custom-built machinery.

Where to Buy a Push Pull Button Switch?

When it comes to buying a Push Pull Button Switch, you have several options.

Point of View 1: Online Stores

One of the most convenient places to buy these switches is online. Websites like Indicator Light offer a wide variety of options, making it easy to find one that fits your needs.

Point of View 2: Specialty Electronics Stores

Specialty electronics stores often carry a variety of switches, including push-pull button switches. These stores allow you to physically inspect the switch before buying.

Point of View 3: Manufacturer Direct

Some people prefer to buy directly from the manufacturer, especially for bulk orders or specialized requirements. This usually requires a business account and may come with minimum order requirements.

What are the Common Problems with Push Pull Button Switches?

Push Pull Button Switches, like any mechanical and electrical device, are subject to wear and tear, and they can encounter various problems over their lifecycle.

Point of View 1: Mechanical Failures

Mechanical issues like a jammed or loose button are common problems. Over time, the spring mechanism inside the switch may weaken, causing the button to lose its ‘snap’ or become stuck in one position.

Point of View 2: Electrical Failures

Electrical problems can also occur, especially if the switch is used in conditions for which it was not designed. Issues like short circuits, broken contacts, or overheating can happen.

Point of View 3: Environmental Factors

Environmental factors such as humidity, temperature, and dust can also affect the longevity and functionality of push-pull button switches. It’s crucial to consider these factors when choosing a switch for specific applications.

How to Troubleshoot a Faulty Push Pull Button Switch?

Troubleshooting a faulty Push Pull Button Switch is often a step-by-step process aimed at identifying and solving the issue. You can learn more about troubleshooting techniques by visiting this guide.

Point of View 1: Visual Inspection

The first step in troubleshooting is usually a visual inspection. Check for visible damages like cracks or burns. Also, check the wiring to ensure all connections are secure.

Point of View 2: Continuity Testing

A continuity test can help identify if the switch is making proper electrical contact when activated. You will need a multimeter for this test, which will indicate whether the switch is working as intended.

Point of View 3: Professional Help

If troubleshooting doesn’t solve the problem or if you’re unsure about what to do, it may be wise to seek professional assistance. An experienced electrician can identify and fix issues quickly and safely.

How to Recycle a Push Pull Button Switch?

In an age where electronic waste is a growing concern, knowing how to properly dispose of or recycle a Push Pull Button Switch is increasingly important.

Point of View 1: Local Recycling Programs

Many communities offer local recycling programs where electronic components like switches can be dropped off for recycling. Check with your local waste management service to see if they accept these types of materials.

Point of View 2: Manufacturer’s Program

Some manufacturers offer recycling programs for their products. This can be a convenient way to dispose of old switches, particularly for businesses that frequently use these components.

Point of View 3: DIY Projects

For the creatively inclined, old push-pull button switches can be repurposed into DIY electronics projects. However, make sure the switch is still in good working condition before using it in a new application.

By exploring these various facets of push-pull button switches, from their functioning and installation to their maintenance and troubleshooting, we can better understand their utility and versatility in a wide range of applications. With proper care and understanding, these switches can serve reliably in both simple and complex electronic setups.

What is the Lifespan of a Push Pull Button Switch?

The lifespan of a push pull button switch can vary depending on a number of factors, such as the quality of the materials used in its construction, its operating conditions, and how often it is used.

Point of View 1: Manufacturer Specifications

Manufacturers usually provide a lifespan estimate for their switches. This is often given as a number of cycles (e.g., 10,000 or 100,000 cycles) and serves as a general guideline.

Point of View 2: Usage Conditions

Switches used in harsh conditions—extreme temperatures, high humidity, or corrosive environments—will generally have a shorter lifespan. Regular maintenance can extend the lifespan somewhat, but it’s essential to choose a switch designed for your specific conditions.

Point of View 3: Quality and Brand

Quality and brand reputation can also affect lifespan. Higher-quality switches made from durable materials are likely to last longer than cheaper alternatives.

How to Wire a 12V Push Pull Button Switch?

When wiring a 12V push pull button switch, there are certain steps to follow to ensure a secure and functional setup. For further insights, you can refer to this comprehensive guide.

Point of View 1: Understand the Terminals

12V push pull button switches usually have multiple terminals, typically labeled for easy identification. Make sure you understand the purpose of each terminal before beginning the wiring process.

Point of View 2: Safety Measures

Always disconnect the power source before you begin the wiring process. Use insulated tools and wear protective gear to minimize the risk of electric shock.

Point of View 3: Testing

After completing the wiring, but before reconnecting the power, it’s wise to test the connections with a multimeter. This ensures that the switch is wired correctly and will operate as expected.

What is the Difference Between Push Button and Push Pull Button Switches?

It’s easy to confuse push button and push pull button switches, but they are distinct types of switches each with their own unique characteristics and applications.

Point of View 1: Functionality

Push button switches are generally momentary, meaning they are active only when pressed. Push pull button switches, on the other hand, maintain their state until toggled again. They have both a push and a pull function that changes their state.

Point of View 2: Applications

Push button switches are commonly used in applications requiring momentary input, like a computer keyboard or doorbell. Push pull button switches are often used in situations where a switch needs to maintain its state, such as turning a device on or off.

Point of View 3: Complexity

Push pull button switches are generally more complex in terms of internal mechanics due to their ability to maintain states. This can make them slightly more expensive and potentially more prone to mechanical failure over time.

This extensive guide has covered various aspects of push pull button switches, providing a comprehensive look at their operation, applications, and troubleshooting. Whether you’re a seasoned technician or a DIY enthusiast, understanding these switches can make your projects more efficient and effective.

How Do I Choose the Right Push Pull Button Switch for My Application?

Choosing the right Push Pull Button Switch for your application is crucial for ensuring reliability and effectiveness. A poorly chosen switch could result in malfunctions or even safety risks.

Point of View 1: Electrical Specifications

First, you need to know the electrical specifications of your application, including the voltage and current. Different switches are designed to handle different levels of electrical load.

Point of View 2: Operating Environment

Consider the environment in which the switch will be used. If it’s a corrosive or high-humidity environment, you’ll need a switch designed to withstand these conditions.

Point of View 3: Functionality Needs

Also consider the functionality you need. Do you need a simple on-off switch, or something more complex with multiple states? This will help you decide between a simple push button switch and a more complex push-pull button switch.

Are There Heavy-Duty Push Pull Button Switches Available?

Yes, heavy-duty Push Pull Button Switches are available for applications that require robust performance under challenging conditions. These switches often come with added features such as waterproofing or higher electrical ratings.

Point of View 1: Industrial Applications

Heavy-duty switches are often used in industrial settings where they might be exposed to extreme conditions such as high temperatures, corrosive materials, or heavy mechanical stress.

Point of View 2: Material Considerations

These switches are often made of materials designed to withstand harsh conditions, like high-grade plastics or metals. They may also include additional sealing to prevent the ingress of water or dust.

Point of View 3: Cost

While heavy-duty switches offer enhanced durability and performance, they are generally more expensive than standard push-pull button switches.

How to Understand Push Pull Button Symbols?

Understanding the symbols associated with push-pull button switches can help you read schematics and better implement these switches in your projects. For a detailed explanation, you might find this guide helpful.

Point of View 1: Standard Symbols

Standard symbols for these switches are generally straightforward, often consisting of a circle for the button and lines indicating the connections.

Point of View 2: Special Features

Some symbols indicate special features of the switch, such as whether it’s a momentary or latching switch, or if it has an LED indicator.

Point of View 3: Manufacturer Variations

While there are standard symbols, some manufacturers use variations or additional symbols to indicate specific features of their switches. Always refer to the manufacturer’s documentation for the most accurate information.

This guide has thoroughly explored the various aspects of push-pull button switches. By understanding their operation, applications, and potential issues, you can make informed decisions whether you are a hobbyist, a professional, or someone in between.

What are the Common Problems with Push Pull Button Switches?

Understanding the common issues that may arise with push pull button switches can save time and resources in the long run. Awareness of potential problems will also help you select the right switch for your needs.

Point of View 1: Contact Issues

One common problem is contact failure. This occurs when the internal contacts of the switch become worn or dirty, leading to unreliable switching. Regular maintenance can help alleviate this issue.

Point of View 2: Mechanical Failures

Mechanical parts inside the switch can wear out over time, particularly in heavy-duty push-pull switches used in challenging conditions. Keeping an eye out for signs of wear can help you replace the switch before it fails.

Point of View 3: Environmental Factors

Switches used in corrosive or high-temperature environments may fail sooner than those used in more benign settings. Choose a switch designed for your specific environmental conditions to mitigate this risk.

How Does Push Pull Button Switch Wiring Work?

Wiring a push pull button switch may seem daunting, but understanding the basic principles can simplify the task. For a step-by-step guide, you can refer to this resource.

Point of View 1: Understanding Wiring Diagrams

Push-pull switch wiring diagrams are generally provided by the manufacturer. Understanding these diagrams is essential for correct installation and operation.

Point of View 2: Tools Required

Proper tools, such as a wire stripper and soldering iron, can make the wiring process smoother. Always use tools that are in good condition to ensure a secure connection.

Point of View 3: Safety Precautions

As with any electrical work, safety should be your top priority. Always disconnect the power supply and take necessary safety measures to prevent any accidents.

What are Auto Toggle Switches and How Do They Differ from Push Pull Button Switches?

Auto toggle switches are a specific type of switch commonly used in automotive applications. They differ from push pull button switches in several key ways.

Point of View 1: Functionality

Auto toggle switches typically work by flipping a lever or turning a knob, unlike push pull button switches, which require a pushing and pulling action.

Point of View 2: Use Cases

Auto toggle switches are commonly used in automotive control panels for functions like turning on the headlights or activating the windshield wipers. Push pull button switches, on the other hand, are more versatile and can be found in a variety of settings, not just automotive.

Point of View 3: Durability

Auto toggle switches are often built to be very robust to withstand the conditions in an automotive setting, including vibrations and temperature changes.

Can 12 Volt Push Pull Button Switches Be Used in Household Applications?

The 12-volt push pull button switch is commonly found in automotive applications, but its usage can extend to household projects as well.

Point of View 1: Power Compatibility

The key consideration here is voltage compatibility. If the household application runs on a 12-volt power supply, then a 12-volt push pull button switch would be appropriate.

Point of View 2: Current Ratings

Another factor to consider is the current rating of the switch. Make sure the switch can handle the current that your household application will draw.

Point of View 3: Practicality

While it’s technically possible to use a 12-volt switch in a household setting, consider whether it’s the most practical choice given the other types of switches available. For instance, household switches are often designed to fit standard electrical boxes.

What is the Importance of a Push-Pull Switch Wiring Diagram?

A push-pull switch wiring diagram is vital for proper installation and operation of the switch. For a detailed guide on wiring, visit this page.

Point of View 1: Avoiding Mistakes

Having a clear wiring diagram minimizes the risk of making mistakes during installation, which can lead to malfunctions or even short circuits.

Point of View 2: Troubleshooting

A well-detailed wiring diagram can also assist in troubleshooting any issues with the switch. It serves as a roadmap that can help pinpoint where a problem may be occurring.

Point of View 3: Documentation

It’s good practice to keep the wiring diagram as part of your project’s documentation. This can be invaluable for future modifications or repairs.

How Do You Wire a 12-Volt Push Pull Button Switch?

Wiring a 12-volt push pull button switch involves several crucial steps for proper functionality and safety. You can learn more about 12-volt switches here.

Point of View 1: Understanding the Terminals

Firstly, understand the terminals on the switch. Typically, there will be a power input terminal, an output terminal to the device being controlled, and possibly a ground terminal.

Point of View 2: Wire Gauge

The wire gauge should be appropriate for the current the circuit will carry. Using a wire gauge that’s too thin could lead to overheating and potential failure.

Point of View 3: Testing

Before making the final connections, it’s wise to test the switch with a multimeter to ensure it’s functioning correctly. This can prevent issues down the line.

Conclusion

In summary, this article has extensively covered the facets of push pull button switches. From their wiring, common issues, and usage in various applications to their differences from other types of switches, this guide aims to provide a comprehensive understanding of this versatile component.