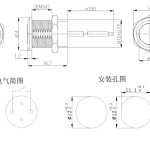

Product Drawings:

Momentary Push Button Switch Normally Closed

- Name:Momentary Push Button Switch Normally Cosed

- Model:GQB16

- Head Type:Falt Head

- Size:16mm

- Switching Functions:Momentary

- Contact Configuration:1NO

- Rated Voltage: 3mA~15A

- Voltage Options:12V-250V /DC

- Material:ABS plastic, Plastic

- Download Certification:CE, CCC, ROSH, UL

- Email:inquiry@cnylin.com.cn

Product Parameters:

| Product Name | Momentary Push Button Switch Normally Closed |

| Operation Type | Latching |

| Light Voltage | DC 12V |

| Contact Type | 1NO |

| Material | Plastic |

| Mounting Hole Dia. | 16mm |

| Included Components | Micro Switch (optional, not included) |

Video of other button switch wiring

How to wire a Push Button Off with led?

Generally speaking, a typical wiring process involves connecting the switch’s terminals to the power source and the load. To elaborate, the following steps are commonly taken:

- Disconnect Power: Always ensure to turn off and disconnect the power source before starting any wiring work to prevent accidents.

- Identify Terminals: Examine the switch for the marked terminals. Commonly, you’ll find COM (common), NO (normally open), and NC (normally closed) terminals.

- Prepare Wires: Strip the insulation off the wire tips that will be connected to the switch terminals.

- Connect to Power: Connect the live wire from the power source to the COM terminal.

- Connect to Load: The NO or NC terminal will be connected to the load, based on whether you need the switch to be ‘off’ or ‘on’ by default.

- Additional Connections: In some cases, you might have to wire additional components like LEDs or resistors. This depends on the type of flush push button switch you are using.

- Testing: After all the connections are made, re-connect the power supply and test the switch’s functionality to ensure proper wiring.

- Secure the Wiring: Use electrical tape or wire nuts to secure all the connections.

- Reassemble: Close the panel or housing where the switch is installed.

- Final Testing: Turn the power back on and test the switch again to confirm it’s working as expected.

For a step-by-step guide on how to wire a flush push button switch, you can refer to this article.

Related products:

What is a Push Button Off Switch and How Does it Work?

A Push Button Off Switch is a simple electronic component that controls the flow of electricity within a circuit. You press the button to break the circuit, turning off whatever device it controls. These switches are commonly used in various applications, from consumer electronics to industrial machines. There are various types of push button switches, including momentary and latching switches. The former reverts to its original state after the button is released, while the latter remains in its altered state until pressed again. For further insights into what a push button switch is, you can visit here.

- Consumer Perspective: Push button off switches are highly intuitive and easy to use, which is why they are commonly found in household appliances.

- Industrial Perspective: In industrial settings, these switches are usually hard-wearing and can withstand heavy-duty usage.

- Electrical Engineering Perspective: From an electrical standpoint, the push button off switch acts as a simple mechanism to interrupt electrical flow.

Table of Contents

Comprehensive Guide to Momentary Push Button Switch Normally Closed

Are you baffled by the intricacies of normally closed momentary push button switches? From understanding how to wire them to finding out if they’re fit for wet environments, this comprehensive guide provides answers from multiple perspectives: electricians, DIY enthusiasts, and manufacturers alike. Learn about dimensions, test methods, and where to buy these crucial components, all aimed at demystifying this common yet often misunderstood switch. Dive in to become an expert!

What Is a Momentary Push Button Switch Normally Closed?

A momentary push button switch normally closed (NC) is a type of switch that, as the name suggests, is in a closed (on) state when not actuated. Pressing the button temporarily opens the circuit, cutting off the current flow. Once the button is released, the circuit goes back to its normally closed state. This is the opposite of a normally open (NO) momentary push button switch, which stays open until pressed. This article aims to answer your most pressing questions about this useful component.

Three Points of View:

- Engineers: From an engineering perspective, a momentary push button switch that is normally closed is essential for control circuits and can be integrated into various systems to serve as an interrupter or circuit breaker.

- DIY Enthusiasts: For hobbyists, these switches are practical for small home projects that require a default ON state but occasionally need to be turned off without the use of a permanent switch.

- Manufacturers: For those producing electronic devices, incorporating a normally closed momentary push button switch can contribute to the safety and user-friendliness of a product.

To understand more about the waterproof varieties, you can read about it here.

How Does a Normally Closed Momentary Push Button Switch Work?

Understanding the operational principles behind a normally closed momentary push button switch is vital. When unpressed, the circuit is closed, meaning that current can flow freely. Once the button is pressed, the circuit opens, interrupting the flow of current temporarily. Releasing the button returns the circuit to its normally closed state.

Three Points of View:

- Electrical Principles: In electrical terms, the switch operates on a simple open-close principle, depending on the actuation force applied to the button.

- Mechanical Design: Mechanically, these switches are designed with springs that push the contacts back to the closed position once the force is removed.

- User Interface: For end-users, the tactile feedback provided by the switch often serves as a cue, informing them that an action (either the breaking or making of a circuit) has occurred.

For those interested in 12V round switches, this resource is highly recommended.

What Are the Typical Applications for Normally Closed Momentary Push Button Switches?

Normally closed momentary push button switches are used in a variety of applications. Their key advantage is that they ensure a circuit remains on by default, only being interrupted when the button is pressed.

Three Points of View:

- Industrial Settings: In industrial applications, these switches often serve as emergency stop buttons or reset buttons for machinery.

- Automotive Industry: In cars, they can serve as ignition switches or control switches for various functionalities.

- Consumer Electronics: In everyday electronics like home appliances, they serve as reset or calibration buttons.

For a wide range of momentary switches, you can visit this page.

What Materials Are Normally Closed Momentary Push Button Switches Made From?

These switches are made from a variety of materials depending on their intended use. Common materials include plastic, metal, and sometimes rubber for waterproofing.

Three Points of View:

- Material Engineers: Plastic is generally used for low-cost applications, while metal switches are preferred for more robust, industrial uses.

- End-Users: From the user’s perspective, the material can affect the feel and feedback of the switch, with metal usually providing a more substantial feel.

- Environmental Considerations: For outdoor or harsh environments, materials like stainless steel or specially coated plastics may be used for corrosion resistance.

To know more about the meaning and types of momentary switches, check this out.

What Are the Electrical Ratings for These Switches?

Electrical ratings for these switches usually range from low-voltage applications (below 12V) to industrial-grade switches that can handle several hundred volts and amps. Ratings can include maximum voltage, current, and sometimes temperature.

Three Points of View:

- Electrical Engineers: The voltage and current ratings must match the application to avoid malfunctions or damages.

- Manufacturers: These ratings define the limits within which the switch can operate safely and are a key factor in product certification.

- Users: Users should be aware of these ratings to ensure they are using the switch safely and effectively.

To explore mini push button switches, consider visiting this site.

How Do I Wire a Normally Closed Momentary Push Button Switch?

Wiring a normally closed momentary push button switch involves connecting the switch in series with the load and power supply. The wiring will depend on whether the switch is a single-pole single-throw (SPST) or a more complex type.

Three Points of View:

- Electricians: For professionals, wiring these switches is straightforward, often involving only two or three wires depending on the switch type.

- DIY Enthusiasts: For hobbyists, understanding the diagram and instructions is crucial to safely and effectively integrate the switch into their projects.

- Manufacturers: For those mass-producing electronics, wiring these switches involves automated processes, ensuring consistency and reliability.

For those looking for detailed information, this normally closed push button diagram can serve as a valuable resource.

What Are the Dimensions of Normally Closed Momentary Push Button Switches?

The dimensions of a normally closed momentary push button switch can vary widely depending on the application. Sizes can range from mini switches less than a centimeter in diameter to larger industrial types.

Three Points of View:

- Design Engineers: The dimensions are chosen based on the available space in the product and ease of access for the user.

- Manufacturers: Size considerations also affect the cost and materials needed for mass production.

- Users: From a user’s perspective, the size of the button can affect its ease of use and visibility.

For car ignition switches, you can visit this page for different dimensions and types.

Can These Switches Be Used in Wet Environments?

Yes, certain types of normally closed momentary push button switches are designed to be waterproof or water-resistant. These are ideal for use in wet environments or outdoor applications.

Three Points of View:

- Environmental Engineers: Special coatings and materials are used to provide the necessary water and dust resistance.

- Outdoor Enthusiasts: These waterproof switches are often used in marine or outdoor applications where exposure to the elements is likely.

- Industrial Use: In industrial settings, water-resistant switches are crucial for safety, especially in wet or humid environments.

To explore the waterproof push button switches, here is a useful link.

How Do I Test a Normally Closed Momentary Push Button Switch?

Testing a normally closed momentary push button switch involves using a multimeter to measure continuity or resistance when the button is pressed and released.

Three Points of View:

- Quality Control: For manufacturers, rigorous testing processes are in place to ensure product quality.

- Maintenance Teams: Periodic testing is crucial in industrial settings to prevent failure and ensure safety.

- DIY Enthusiasts: For hobbyists, simple continuity tests with a multimeter can help verify the functionality of the switch.

For 12-volt momentary push button switches, this link provides valuable information.

Where Can I Buy a Normally Closed Momentary Push Button Switch?

You can purchase these switches from various suppliers including electronics stores, online platforms, and specialized industrial suppliers.

Three Points of View:

- Purchasers: Bulk orders usually come from suppliers specializing in industrial electronics.

- Consumers: For individual or smaller quantities, online platforms or local electronics stores are convenient.

- Manufacturers: Direct purchases from manufacturers may offer customization options.

For an assortment of momentary push button switches, you may refer to this category page.

These small toggle switches have the advantage of being compact and simple to install and use. They are usually constructed using plastic or metal materials and can be utilized in various applications, including regulating circuit switching states in household appliances or industrial equipment. Furthermore, these switches typically exhibit good reliability and durability, enabling them to endure numerous operations without succumbing to wear and tear or incurring damage.

If you are interested in our products, please visit our website at www.indicatorlight.com.

If you are interested in our products, please visit our Amazon store at www.amazon.com: FILN