In a world where precision drives progress, machinery equipped with the right components not only enhances efficiency but also ensures safety. A silent yet pivotal player in this realm is the ‘limit switch‘ – a device that plays an instrumental role in controlling machines with remarkable accuracy. This essential guide unlocks the functions, types, and applications of limit switches, and how they underpin modern automated systems.

The Essential Guide to Limit Switches for Superior Machine Control

What is a Limit Switch?

The Basic Composition of a Limit Switch

At its core, a limit switch comprises an actuator that’s mechanically linked to a set of electrical contacts. When the actuator comes into contact with an object, or reaches a predetermined limit, it operates the switch. This action can make or break an electrical circuit, initiating various responses from machinery – from starting and stopping motors to activating alarms.

-

Actuator/Operating Head: This is the part of the switch that comes into direct contact with the physical object or target. When the object moves the actuator, it triggers the switch. Actuators can come in various forms, such as plunger, lever, or roller, depending on the application.

-

Switch Body: The body houses the contact blocks and the mechanical linkages to the actuator. It contains the electrical contacts and the terminals for connecting the switch to an electrical circuit.

-

Contact Blocks: These are the electrical contacts that make or break the electrical connection when the switch is triggered. They may be normally open (NO), normally closed (NC), or a combination of both, allowing for different types of control logic.

-

Terminals: These are the connection points used to connect the switch to the electrical circuit. They are typically screw-type or plug-in connectors for ease of installation and maintenance.

-

Enclosure: The enclosure protects the internal components of the limit switch from dust, moisture, and other environmental elements. The robustness of the enclosure is often rated by an Ingress Protection (IP) rating, which indicates the level of protection against solids and liquids.

-

Mechanical Linkage: This component translates the movement of the actuator to the contacts. It is designed to ensure that a small movement at the actuator translates effectively to the contacts.

The Critical Role of Limit Switches in Modern Machinery

-

Precision Control: Limit switches provide precise control over machinery by indicating the presence or absence of objects or the position of mechanical parts. This precision is crucial in applications where exact movements are necessary, such as in automated assembly lines, packaging machinery, and CNC (Computer Numerical Control) machines.

-

Safety and Emergency Stop Functions: Safety is paramount in any mechanical system, and limit switches contribute to this by acting as emergency stop buttons or safety interlocks. They can halt machinery operation if a part moves out of its designated area or if a system component operates beyond its safe limits, preventing accidents and protecting equipment.

-

Automation and Efficiency: In automated systems, limit switches reduce the need for constant human monitoring by automatically controlling the start, stop, and reverse operations of machinery based on the position of objects or components. This automation increases efficiency, reduces labor costs, and can lead to higher production rates.

-

Feedback for Control Systems: Limit switches provide essential feedback to control systems regarding the position of moving parts within machinery. This feedback is used to make real-time adjustments, ensuring the system operates smoothly and according to predefined parameters.

-

End of Travel Detection: They are frequently used to detect the end of travel of a moving component, ensuring that machinery operates within its mechanical limits. This detection is crucial in preventing over-travel, which could lead to damage or wear on mechanical components.

-

Versatility and Reliability: With a variety of actuator types and configurations available, limit switches can be tailored to a wide range of applications and environments, including those with high temperatures, moisture, or explosive atmospheres. Their mechanical operation ensures reliability even in conditions where electronic sensors might fail.

What is the difference between a limit switch and a push button switch?

- Operation Mechanism: A limit switch is activated by the physical movement or presence of an object that engages the switch’s actuator.

- Function: It’s usually used to detect the limit of travel of an object, hence the name. When the set point is reached, the device operates the switch.

- Applications: Commonly found in machinery, manufacturing lines, elevators, and other equipment that require motion control or position sensing.

- Durability: Often designed to withstand industrial conditions and can be very durable.

- Operation Mechanism: A push button switch requires manual operation by a person. It is triggered by someone physically pushing a button.

- Function: Its primary function is to open or close an electrical circuit. Push button switches can be momentary (switch is active only while the button is pressed) or maintained (press once to activate, press again to deactivate).

- Applications: Used in devices like handheld calculators, doorbells, control panels, and many everyday household or industrial applications.

- Interactive Uses: More interactive as they’re designed for human use and usually require less force to operate compared to a limit switch.

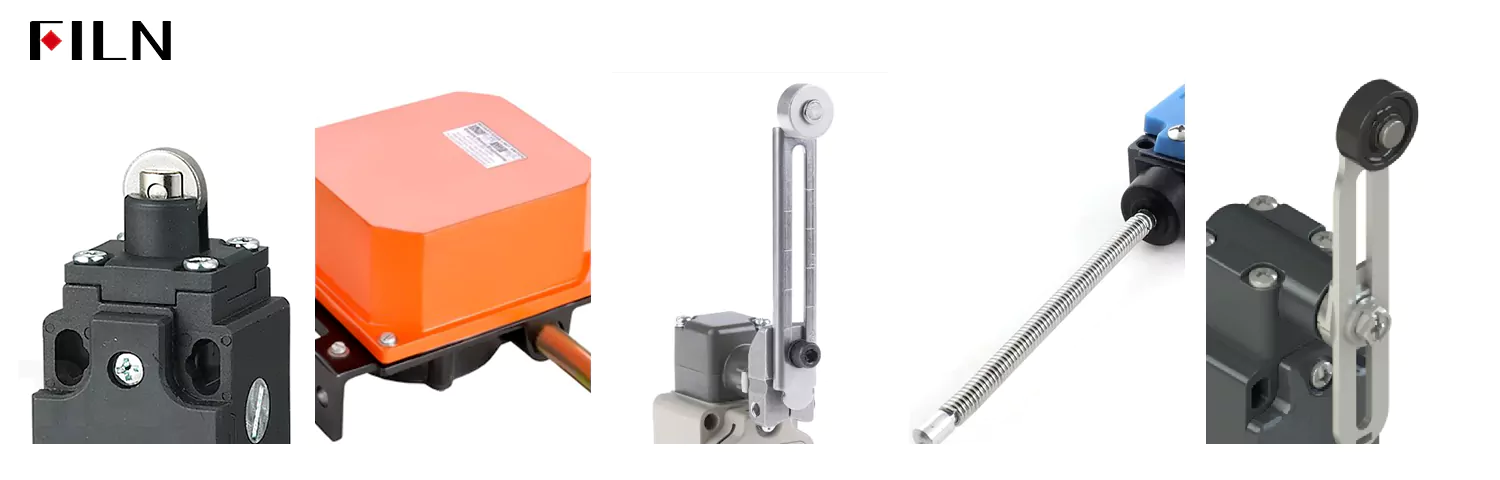

Exploring the Different Types of Limit Switches

-

Plunger Type: This switch features a plunger that is pushed down by an object to activate the switch. They can be further classified into pin plungers and rod plungers, based on the shape of the actuating element.

-

Rotary Type: These switches have an actuator with an attached arm that rotates to activate the switch. The rotary movement either opens or closes the electrical contacts within the switch.

-

Lever Type: Lever type limit switches use a lever arm and roller to detect objects. When an object comes into contact with the roller, the lever moves and actuates the switch.

-

Whisker Type: Whisker limit switches have a very sensitive metal “whisker” that can detect light objects or slight movements that might not trigger other types of switches.

-

Cable Type: Also known as “pull-wire switches,” these activate when tension is applied to a connected cable. They’re used for emergency stops along conveyor systems or other long linear applications.

-

Heavy Duty Type: Built to withstand harsh environments, heavy-duty limit switches offer rugged enclosures and actuation mechanisms suitable for challenging industrial conditions.

-

Compact/Miniature Type: These switches are designed for applications where space is at a premium. Despite their small size, they can offer the same functionality as larger switches.

-

Safety Interlock Switch: These are designed to be used as safety devices that ensure that a machine is shut down if certain conditions are not met, such as when a gate or door is opened.

-

Precision and Miniature Precision Switches: Offering high accuracy, these switches are used where precise control or small movements need to be monitored. They typically have a smaller differential travel and higher repeatability.

Each type of limit switch will have variations in the type of actuator, force required to trigger the switch, electrical specifications, and enclosures to suit a wide array of environments and applications. Choosing the right type of limit switch depends on factors such as the operating environment, space constraints, the nature and speed of the actuating force, and electrical load requirements.

What are the applications of limit switches?

-

Industrial Automation: In conveyor systems, limit switches are used to detect the presence or absence of items and control the flow of products. They can also signal when a conveyor belt has reached its end point.

-

Machine Tools: They are integrated into CNC machines for positioning control and to ensure tools do not exceed their travel limits.

-

Elevators and Lifts: Limit switches ensure the elevator or lift stops at the correct floor level and can activate safety mechanisms in case of failure.

-

Cranes and Hoists: They provide positioning information and enforce maximum and minimum height limits to prevent over-travel.

-

Robotics: Robots use limit switches to detect the end of a movement path or to confirm the successful completion of an operation, like picking up an item.

-

Doors and Gates: Limit switches are used to detect if a door or gate is fully opened or closed, often for security and safety purposes.

-

Material Handling Equipment: In forklifts, limit switches can indicate the position of the forks and control the lifting mechanism.

-

Packaging Machinery: They detect product positioning and ensure packaging processes occur at the correct time in the cycle.

-

Home Appliances: Within appliances like washing machines, they are used to detect the position of moving parts like the lid, ensuring the machine does not run when open.

-

Automotive: In the automotive industry, limit switches can be found in assembly lines for vehicle manufacturing where the precise position of components is critical.

-

Agricultural Machinery: In equipment such as tractors and combine harvesters, limit switches can signal when a component is in position for an operation to occur.

-

Heavy Industry: Limit switches can be found in steel mills, foundries, and other heavy industries where equipment must operate under extreme conditions.

How they underpin modern automated systems

-

Feedback for Automated Control: Limit switches provide vital on/off input signals to programmable logic controllers (PLCs) and computer-based control systems, indicating the position of equipment components. This allows automated systems to make decisions based on the physical status of a machine or process.

-

Safety Interlocks: They act as safety devices that can halt operation if a machine part moves outside of its designated operational envelope. This prevents potential damage to the machine, product, and most importantly, safeguards human operators.

-

Positioning and Precision: Precision is crucial in automation. Limit switches offer high repeatability and accuracy, ensuring parts are correctly positioned before moving to the next step of an automated process. This is essential in operations like assembly lines, robotics, and material handling.

-

Sequential Control: Automated systems often involve complex sequences of operations. Limit switches can enable or disable certain actions, ensuring that steps are completed in the correct order.

-

Facilitating Human-Machine Interfaces (HMIs): In combination with indicators and alarms, limit switches contribute to interfaces that allow for human interaction and monitoring of automated systems.

-

End-of-Travel Stops: In automated transport systems like conveyors or automated guided vehicles (AGVs), limit switches indicate when an end-of-travel or home position is reached, allowing for precise stops and starts.

-

Counting and Sorting: In packaging and manufacturing, limit switches can count products and direct them to different locations for sorting or further processing.

-

Machine Maintenance: By monitoring the operation of moving parts, limit switches can signal when maintenance is needed, preventing breakdowns and prolonging the life of the machine.

-

Energy Efficiency: By ensuring machines operate only when necessary and within the required parameters, limit switches contribute to energy-efficient operations, which is an increasingly important aspect of modern industry.

-

Facilitating Automation in Harsh Environments: Heavy-duty limit switches are designed to work in extreme conditions, such as high temperatures, dust, and vibration, thereby ensuring automated processes can be extended to a wider range of industrial settings.

How to Choose the Right Limit Switch

-

Operating Environment:

- Temperature: Ensure the switch can handle the operating temperature range of the environment.

- Humidity: Check for the switch’s resistance to moisture or for the need for a sealed unit.

- Vibration and Shock: Some switches are designed to resist mechanical shock and vibration.

- Corrosives: In chemically aggressive environments, choose a switch with suitable housing and seal materials.

-

Load and Electrical Requirements:

- Voltage and Current: Match the switch’s electrical rating with the load it needs to control.

- AC vs. DC Loads: Some switches are better suited for alternating current (AC) while others for direct current (DC).

- Inrush Current: If the switch will control an inductive load, ensure it can handle the inrush current.

-

Physical Constraints and Actuator Type:

- Space: Assess the size constraints and fit of the switch in the required space.

- Actuator Type: Plunger, lever, roller plunger, whisker, etc., need to be chosen based on the kind of physical contact expected.

- Actuator Length and Positioning: Select an actuator that will engage properly with the moving part.

-

Mechanical Life:

- Durability: The switch should have a mechanical life that exceeds the expected number of operations in the application.

-

Switching Frequency:

- The switch should be able to handle the expected cycle rate without premature failure.

-

Precision and Repeatability:

- The switch should be able to actuate at the specific point needed every time without significant variation.

-

Installation and Maintenance:

- Accessibility for installation and maintenance should be considered, as it affects operating costs over time.

- Snap-action switches require little force to activate and can be useful in delicate applications.

-

Certifications and Standards:

- Ensure the limit switch meets relevant industry standards, such as IP ratings for ingress protection, UL listings, CE markings, and any other regulations pertinent to the application.

-

Cost and Availability:

- Consider the total cost of ownership, which includes purchase price, lifespan, and any maintenance expenses.

- Ensure availability for replacement parts and future maintenance needs.

Limit switch FAQ

-

What is the function of a limit switch?

A limit switch is used to detect the presence or absence of an object, or to detect a specific motion limit of a moving part often for the purpose of providing power, grounding, or interrupting a circuit in an automation or safety control system. -

What is a limit switch used for?

A limit switch is typically used for control purposes in machinery and equipment, where it can signal to a machine’s control system to perform a particular action when an object reaches a certain point, such as stopping a motor or starting a process. -

How many types of limit switches are there?

There are several types of limit switches, including rotary, lever, plunger, and roller types, each with various actuator styles and configurations suitable for different applications. -

What is a mechanical limit switch?

A mechanical limit switch is a type of electromechanical device that consists of an actuator mechanically linked to a set of contacts. When an object comes into contact with the actuator, the device operates the contacts to make or break an electrical connection. -

Why is the limit switch important?

Limit switches are important because they provide essential information about mechanical and system status to the control system, which is crucial for the safe and precise operation of machinery. They help in preventing equipment over-travel and ensuring proper motion control. -

What is the difference between a proximity switch and a limit switch?

A proximity switch can detect the presence or absence of an object without physical contact, using various sensing methods like inductive, capacitive, or magnetic properties. In contrast, a limit switch requires physical contact with the actuator to operate the contacts.